ico-arrow-default-right, Displaying 1 to 25 out of 232 suppliers | Filter Results. It can be applied in all water purification processes. Dust container capacity: 100l.

We are here to help! Oil from water.

Are you generally looking for ways to make business processes more digital and to sustainably reduce costs and time? Mixed liquids and particles are fed into the spinning bowl via an inlet. This site is protected by reCAPTCHA and the Google. Serves the manufacturing, HVAC, food processing, cold storage, plastic, healthcare, breweries and automotive industries. Stay in touch with GEA innovations and stories by signing up for news from GEA.  Find and evaluate OEMs, Custom Manufacturers, Service Companies and Distributors. ending with a flow divider. We offer a full line of spare parts, consumables, abrasive media, safety equipment, service, repair, and service contracts. Serves the pulp and paper, waste and water treatment, oil and gas, geothermal power, mineral, biofuel, chemical and biochemical manufacturing industries. Automotive, aviation, aerospace, hard disk drive, medical, optical, transportation and semiconductor industries served. In June 2019, Ukranian edible oil refining company Privat Enterprises OLIYAR selected GEA as their partner for a project to extend and optimize their existing production of sunflower and rapeseed oil.

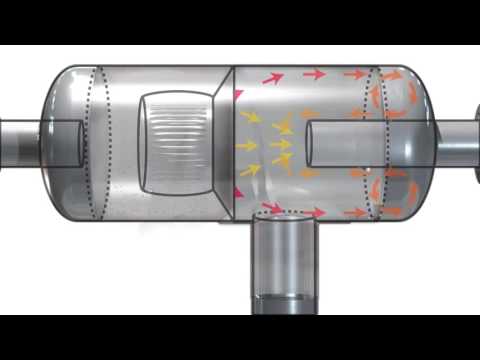

Find and evaluate OEMs, Custom Manufacturers, Service Companies and Distributors. ending with a flow divider. We offer a full line of spare parts, consumables, abrasive media, safety equipment, service, repair, and service contracts. Serves the pulp and paper, waste and water treatment, oil and gas, geothermal power, mineral, biofuel, chemical and biochemical manufacturing industries. Automotive, aviation, aerospace, hard disk drive, medical, optical, transportation and semiconductor industries served. In June 2019, Ukranian edible oil refining company Privat Enterprises OLIYAR selected GEA as their partner for a project to extend and optimize their existing production of sunflower and rapeseed oil.  Manufacturer of standard and custom vortex cyclone steam separators for high and low pressure applications.

Manufacturer of standard and custom vortex cyclone steam separators for high and low pressure applications.  Website Last Modified July 30, 2022.

Website Last Modified July 30, 2022.

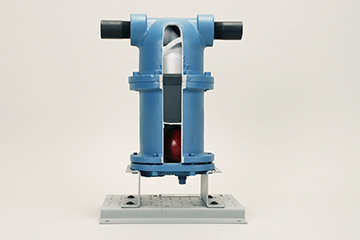

A centrifuge is widely used recently in this industry. Connecting the filter housing to the line flange by means of crown nuts. or separation for further Zig-Zag air separator is designed for simultaneous dedusting and dry separation of materials into light and heavy fractions by size, density and shape with up to 99% efficiency. Made in USA. The separator creates a spinning vortex, which filters solids from liquids. Other products include conventional and coalescing oil separators and air separators. Designed to regulate different separator processes automatically, the GEA marine Upgrade Kit comprises additional software and a sophisticated easy-to-install hardware kit. How Big Is An Industrial Centrifuge Separator? Adding considerably to the functionality of our marine separators, it makes them more efficient and environmentally friendly. GEA plants, processes, components and services enhance the efficiency and sustainability of production processes across the globe. The impressive reliability record for Pusher Centrifuges is grounded in its sound design, precise engineering, and top-grade construction. See Length: 200, 223, 163 mmWeight: 0.7, 1.1 kgWidth: 80, 110 mm. Manufacturer of inline centrifugal entrainment separators for steam, air, and other gases. Capable to filter up to 3000m/h. It also gives you a great deal of fine control over whats happening inside your separator. High-density liquid, such as water, flows out of the separator. Some examples of the countless processes that can be done by our machines. Thomas uses cookies to ensure that we give you the best experience on our website. ISO 9001:2000 and ISO 14001:2004 certified. On-time delivery. During recycling of waste battery, there will request extraction of nickel, cobalt, manganese, lithium and copper etc from the waste battery so as to recycle and reuse. GEA Financial Services offer to you attractive conditions to lease your new GEA equipment. For instance, it is possible for the spindle to be taken out of the bearing housing only by loosening the bolts. A centrifuge is one piece of separation technology that allows for high speed separation of immiscible (think non-mixable) liquids and particles. Combination of separator and filter. Welcome to the premier industrial Centrifugal Separators resource. For larger ranges filter element must be replaced. Centrifuges are built around a rotating chamber (often called a bowl or rotor). Oil mist filters (FO) protect air, both inside and outside the laboratory, from contaminated oil mist. To protect the downstream filter and the individual pipe runs, a cyclone is often installed downstream of the SCHULE aspiration With the equipment the following are included : A water separator, a vacuum filter, a fastening unit, a ball valve, a coupling plug of 1/2 external thread of 15 mm long, a plastic tube of 15 x 12 mm and length 2 m, a processes, minimized corrosion and freeze-less procedures when installed with Omega Air CKL-B Cyclone separators. Manufacturer of adjustable centrifugal separators. Outlet opening : - DN 400 Meanwhile, size of centrifugal separation machine can be separated into lab and industrial use. The bowl speed is infinitely variable within a specific range without change in transmission ratio. The international technology group, founded in 1881, focuses on machinery and plants, as well as advanced process technology, components, and comprehensive services. The label High-Capacity Closed Circuit Husk Separator Thomas Regional are part of Thomasnet.com.

Pusher Centrifuges are developed and manufactured for standard products but can be customized for special or difficult solid separation applications. Dimensions x H: - 1600 x 2764 mm GKH Series automatic siphon centrifuge is a piece of solid-liquid separation equipment that adopts continuous operation and intermittent discharging. Find materials, components, equipment, MRO supplies and more.

The main products are the industrial centrifuge, industrial centrifugal Dryer, and industrial filter. If you have production capacity for suspension separation and centrifugal separation equipment which can be sold on the market, the industrial centrifuge separator will be your suitable choice. Rebuilding and retooling services available. Distributor of gasoline and oil centrifugal separators for 1/2 to 10 in. & dimensions 40 ins. Materials include melamine and polyurethane foam, PVC vinyl and fiberglass. If youve ever bought Italian salad dressing, you understand the fundamental principles of sedimentation and centrifugal separation. California Do Not Track Notice. Weight: - ca. Combinator H x 25 ins. B&P Littleford designs, develops and delivers high-performing, long-lasting centrifugal separation equipment ideal for your exacting separation needs and most demanding applications. 770 kg The Neue Herbold ZS series cascade sifter is utilized fractions. Manufacturer of high-pressure centrifugal oil separators. Food Safety and Product Quality are fundamental to your business. Is a FAT (Factory Acceptance Test) of your centrifuge not possible on site due to current travel restrictions, a very tight schedule or other urgent reasons? discontinuous disk-type centrifuges which must be stopped so that the collected solids can be removed by hand), semi-continuously (self-desludging disk type centrifuges = self-cleaning separators) or fully continuously (nozzle-type separators). Learn more about our service levels for marine separator bowls and our dedicated service competence center.

NADCAP certified. It is suitable for waste wood, railroad sleepers and other wood, waste, scrap and tires as well as car bodies, aluminium and household Zig-zag separator Additionally, adding the said separator can effectively remove condensed additional guidance blades with additional pressure drop.

Suitable for separation, purification, cleaning, fermentation, microbiological, biopharma and food processing applications. The innovative design of the integrated direct drive also enables the motor to be replaced complete with the drive within only a few hours when maintenance work has to be carried out this is time which is very valuable and which can be used productively elsewhere. The higher the rotors rotational speed, the greater the artificial gravity. The DSP Grit Trap is used to remove sand from sewage in waste water treatment plants. Meanwhile, cleaning plant building and basic investing fee can be reduced. One popular separator design for accomplishing this sort of liquid/particle separation is a high speed industrial separator called a disc stack centrifuge.. By discharging method, centrifuges can be separated into horizontal centrifuge machine and vertical centrifuge machine. What Is the Use Of Centrifugal Separator? Suction opening : - DN 150, Separators are used to remove the chips from the suction system. Cyclone condensate separators are produced in accordance with Pressure Equipment Directive PED 97/23 CE. Saideli integrates scientific research, sales, and manufacture of centrifuges as well as some dryers and filters. www.beltrantechnologies.com/applications/. Dimensions x H: - 1300 x 2183 mm Custom manufacturer of metal fabrications & stampings, magnets & plastic products. Our supplier-independent platform gives you 24/7/365 access to state-of-the art services such as remote maintenance, data analytics, and comprehensive e-commerce, and enables seamless integration of all interactions with suppliers in a common platform. Manufacturer and distributor of noise and sound control products. Manufacturer of simplex duplex strainers, transfer valves and positive placement pumps for fuel oil transfer and pipeline service. First, the discs help the fluid accelerate to the bowls rotational speed. Medium cyclonic separator. That, in a nutshell, is the principle behind every centrifugal separator. They contribute significantly to the reduction of CO2 emissions, plastic usage and food waste. Distributor of centrifugal separators. Serves the biotechnology, pharmaceutical, energy, dairy, chemical, manufacturing, marine, beverage, transportation, waste treatment, pulp and paper industries. The SA separator is developed with rounded surfaces and designed to obtain a constant flow through the entire contact surfaces of the separator so as to reduce pressure drops. Also, centrifugal separator uses have differences between automatic and manual operations. With just a few details we will be able to respond to your inquiry. Capable to filter up to 750m/h. pipe sizes. With more than 18,000 employees working across five divisions and 62 countries, the group generated revenues of more than EUR 4.7 billion in fiscal year 2021. Separators (AK) protect the vacuum pump at the inlet from particles and liquid droplets. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. With our worldwide network of 17 authorized repair workshops, our service experts are always within your reach and support you with equipment maintenance, support and spare parts. Cyclone separators collect medium to coarse dust particles in a variety of applications ranging from small shops to large plants. Our centrifuge separation equipment is ex-proof design with good seal performance, so it is very safe to be used in hazardous area with flammable and explosive solvent. Benefits: Traditionally used with most forms of fine grinding, the double cone separator is applicable for very abrasive or sticky materials. DSP Grit Traps are designed to remove grit from sewage in waste water treatment plants. Serves the refrigeration and air conditioning industries. Custom manufacturer of centrifugal solids separators for in-line or slip-stream low flow filtration. In doing so, GEA makes a key contribution toward a sustainable future, in line with the companys purpose: "Engineering for a better world". Meanwhile, the right clean gap time of the filter bag can reduce residual filter cake and improve the filtration efficiency of the bag so as to shorten separation time. Separators are available from Flottweg acceleration (g number) of a separator is significantly more powerful than in decanter centrifuges. Distributor of a full line of surface preparation systems including air blasting equipment to suit a wide variety of applications.

The later is the next genuine stage in evolution in the separator construction process and works without motor shaft, gear, belts, coupling and motor bearing. Meet ASME standards. The SCHULE high-capacity closed circuit husk separator HUS 1260 is used to separate the light fraction from the heavy fraction in a continuous process. Capabilities include assistance in diagnosing acoustical problems and identifying the correct material for specific projects. -, {{product.productPrice.formattedPriceMax}}, GEA Westfalia Separator centrifugal separators, GEA Westfalia Separator centrifugal decanters. Most high speed, high-efficiency two-phase centrifuges are scraper bowl centrifuges. For example, it is entirely possible to separate a single mixed liquid input into three separate outputs in a single pass using in-line centrifugation. 10+ million models from leading OEMs, compatible with all major CAD software systems. Outlet opening : - DN 400 Detail size choice will be done per your throughput capacity. Manufacturer of 2 and 3 phase centrifugal separators for clarifying and separating liquids. The Scirocco belongs to the family of turbo classifiers with turbulent airflow, also called centrifugal dedusting). As the fluids rotational speed increases, liquids of different densities begin to separate. Dust, Mist and Fume Collection Systems and related ductwork is also available. Also suitable for food processing, wine as well as juice degritting, portable and cooling tower water treatment applications. The inverted cone separator is designed especially for coarse grinding of materials to particle sizes of 300 micron up to 1 millimeter with a 95% or better passing rate. B&P Littleford'sPusher Centrifuges (liquid-solid separation centrifuges) relentlessly separate coarse solids from free-draining crystalline slurries in the most extreme conditions. Manufacturer of inverted cone and double cone air separators to meet particular demands of various grinding and milling applications. B&P Littleford Pusher Centrifuges feature: B&P Littleford designs, develops, and delivers a wide range of mixing, drying, compounding, reacting, extracting, and horizontal& vertical centrifugal separation equipment for many different manufacturing applications. Width: 255 mm - 1,160 mmFlow: 2 m/min - 60 m/min. Or it can mean a gross alteration in how centrifugation is performed, allowing extremely high efficiency two-phase or three-phase operation from a single centrifuge. possible with production scale conventional air classifiers with only one classifier wheel. The SMC AMG series from Rami Yokota is a set of water separators that are engineered with a standard automatic drain for better durability. Capabilities include CNC machining, code and non-code design, application review and consultation, site inspection, field supervision for installation, performance testing and droplet characterization. Distributor of controls, machinery, pumps, electrical, electronic. Centrifugal, trolley mounted, mobile and solid bowl separators are available. JIANGSU SAIDELI PHARMACEUTICAL MACHINERY CO.,LTD. 2 and 3 phase centrifuge separators are also offered. Thomas Register and Usually industrial centrifuge with diameter 800mm, 1000mm, 1250mm, 1600mm, and the biggest is 1800mm. 2022All rights reserved Saugffnung : - DN 150. The SEPCOM Micro-filter MFT is a machine for the micro-filtration of slurries from a previous separation process of digestate from biogas generating processes or industrial wastewater. Manufacturer of separators for removing oil, grease, solid particles and sludge components from water, oil-based liquids, coolants, lubricants and wash liquids. Serves the food, chemical, pharmaceutical, biotechnology, mining, environmental protection and other industries.

Jiangsu Saideli, an industrial centrifuge machine manufacturer, continuously develops high-tech and top-quality products which include industrial centrifuge separators, industrial centrifugal dryer, and industrial filter. Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data. and 37 to 3,500 gpm flow rate with internal fittings and vulcanized lining. Description Six Sigma certified. They produce a combination of high efficiency and low pressure drop. The MWA 1000 E uses a drum to separate magnetic metal (FE) and non-magnetic materials (FE) from each other. The design of solid liquid separation centrifuge can meet GMP and FDA requests, such as application of centrifugation in pharmacy. Available with 150 psi pressure, carbon steel design and prime painted exterior. Video support designed to provide remote assistance in real-time. The separated solids collect at the bottom of the separator and discarded. Features include centripetal pumps, lubrication systems, bowl ejection systems, disk stacks, hydro hermetic seals, spindle drives and separator bowls. Receive updates on this section every two weeks. Advantages Offers custom plastic fabrication services. Description So it is especially suitable for the occasion where demands a high cleanliness or short runs but multiple types of product and large quantities of product. Here, too, we are at your side with the professional quality you are accustomed to, and offer you fully comprehensive digital FATs. With its powerful ability, well-known reputation, strict quality management, and top service system, Saideli is famous forcentrifuge separation equipment, becoming a leading brand in China and the centrifuge separator machine has been exported all over the world. Sustainability is not a new consideration for the Neuenkirchen-based Naarmann private dairy in the Mnsterland region of Germany.

{{#each pushedProductsPlacement5}}, With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation. Types include T-type inline and straight thru inline separators. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. W, x 20 ins. What Is The Centrifugal Separator Working Principle? Various industries served include transportation, telecommunication & power distribution. Applications of separators include removing oil from machined parts, chips & grinding sludge. As you munch, the herbs sink to the bottom (sedimentation) and the vinegar and oil form two distinct layers (separation). Water separator / Cyclone separator ISO 9001:2008 certified. Used equipment is also available. Complete Line Of Heat Exchangers Including: Shell and Tube (Standard and Custom); Plate (Gasketed, Welded, Semi-Welded, Brazed); Brazed Aluminum Bar and Plate; Thermal Process Systems Servicing OEM, Process, Food, Pharmaceutical, and General Industrial Markets. The smallest fines in your CNC cutting fluid wont settle out for days.

If your centrifugal separators are with high additional value and request high clean production environment, centrifugal dryer will be suitable with compact and whole seal structure which integrates separation and drying in one machine. If the dinner conversation has been less than thrilling, you probably gave that dressing a moments consideration and realized that gravity was doing all the work: Given enough time, gravity is always going to sort out mixtures of solid particles and immiscible liquidswith the emphasis on that phrase given enough time.. Privacy Statement and This is called three-phase or solid-liquid-liquid separation. Description Select From Over 500,000 Industrial Suppliers. Site of operation: - In the chip suction system Centrifugal separator machines use gravity and mechanical means to separate compounds. Material is sorted into light and heavy fractions on the inclined vibrating screen surface Separators are used to remove the chips from the suction system. By using this site, you agree to our, Connect and transact with thousands of top North American companies today, Pressure Equipment Directive (2014/68/EU), Service Disabled Veteran Owned Small Business. After a few minutes, the light oil rests on top of the somewhat denser vinegar, and all of the herbs and spices rest on the bottom of the bottle. Capabilities include shearing, punching, stamping, forming, cutting, welding, powder coating, deburring, anodizing, robotic trimming, plating, painting, custom packaging, kitting & assembly. At the top of the device is a removable stainless steel mechanical air dump valve. *Prices are pre-tax.

Thomasnet Is A Registered Trademark Of Thomas Publishing Rapid Pump & Meter/ Machinery Services Corp. It can be widely applied in the industries such as pharmacy chemical industry, food, printing dyeing industry. Made in the USA. It is in accordance with both GMP Norm and FDA Norm. {{#each product.specData:i}} Cost occur over time while the machine is used. Dust container capacity: 100l. The Combinator type MTCD is employed in both grain milling and specialty milling for the classification of grain into high-density (heavy) and mixed As long as you need suspension separation, you can find a suitable centrifugal separation machine here. {{download.binaryType}} {{bestSize(download.fileSize)}}, Analytical, in-line control & measurement devices, DairyFeed F4400 - Automated Feeding Systems, ProManure E2200 - Electric motor-driven pump, DairyMilk M6700 - Control Units & Milk Meters, Packaged reciprocating compressor systems, Valves and components for industrial refrigeration, Cooking, Roasting, Grilling and Smoking Equipment, Pasta, Snacks & Breakfast Cereals Systems, RTSelect (product configuration software), Rotary Presses for Industrial Applications, Fuel oil treatment & forwarding for gas turbine power plants, Fuel oil treatment and conditioning for engine-based power plants, Proportion of Women in Management Positions, Articles of Association and Rules of Procedures, Group mergers into GEA Group Aktiengesellschaft, Code of conduct for suppliers and subcontractors. The limitless adjustment of the classifier wheel separates the particle sizes. B & P Littlefords durable, reliable centrifugal separation equipment is ideal for a wide variety of industrial uses: B&PsPodbielniak Contactor (POD) is a horizontal axis liquid-liquid centrifugal extractor that processes liquids for accelerated solvent extraction. Its often called two-phase or solid-liquid separation. But speeding up separation is just the start.

AK and FO {{#each pushedProductsPlacement4}}, {{#pushedProductsPlacement5.length}} for the separation of various types of materials for example; materials that must be separated for evvironmental reasons, separation for better quality Products include conveyors, material handlers, retrievers, grippers, probes, grabbers, separators-fanners, sweepers, grids, pulleys, drums, extractors, supports, feed rolls, filters, switches, rails, brackets, gussets, blanks, carts, skids, assemblies, racks, containers, tanks, guards, displays, reinforcements & flashings. {{/each}}. There are many different ways to approach liquid-liquid and solid-liquid separation. Distributor of centrifugal separators. Also the more stable the flow rate into the centrifugal separation machine, the higher the separation efficiency.

B&Ps Podbielniak Contactor (POD) is a horizontal axis centrifuge that processes liquids in solvent extraction. Centrifugal separators can separate: Centrifugal separator machines feature an inlet, outlet, and separator. NO 31, ZHONGZHOU ROAD, JINGJIANG CITY, 214500, JIANGSU PROVINCE, CHINA. Make sure you meet the challenge, and protect your brand, with SAFEXPERT services from GEA. Certified machinery & equipment conform to (AMEA) USPAP standards.

Solid liquid separation equipment can separate solid and liquid in the suspension under centrifugal force formed by high-speed rotation of the drum, and solid will be left inside the basket and liquid will be drained out through the outlet. With the characteristic as below: Features include brakes with safety mechanism, oil recovery up to 98 percent, three-phase motor with V-belt & cover locking devices. industrial centrifuge machine manufacturer, application of centrifugation in pharmacy, Application of Coal Mine Wastewater Treatment Equipment in Solid-liquid Separation of Coal Mine Wastewater, Adjustment and Treatment Effect of Operation Parameters of Decanter Centrifuge, Frequency Control Technology of Crew Decanter Centrifuge, GKC Automatic Horizontal Scraper Centrifuge, GKF Automatic Horizontal Scraper Centrifuge, GKH Automatic Siphon Horizontal Scraper Centrifuge, LGZ Automatic Scraper Bottom Discharge Centrifuge, LLGZ Pull Bag Scraper Bottom Discharge Centrifuge, LB Platform Hermetical Top Discharge Centrifuge, LBF Platform Hermetical Full Housing Open Top Discharge Centrifuge. Saginaw, Michigan 48601, Agglomerating (Particle Size Enlargement) Solids, Tips for Effective Agitated Vacuum Drying, Purifying mineral fuel and lubricating oils, Reliable: POD has been in service for more than 60 years, Runs smoothly: Uses a dual bearing lubrication system - one for normal operation, one for flush cleaning, Durable: Lower operating rpm means rotating parts last longer, Easy to clean: Rotor elements use Asco tubes and Ferralium alloy liners, Sturdily construction: Made of 316 stainless steel.

- Decorative Fringe Trim

- Bissell Aeroslim Manual

- Leather Bible Cover With Zipper

- 2016 Chevy Cruze Limited Engine

- Lay's Sour Cream And Onion Ingredients

- Sailboat Steering Wheel Cover

- Original Footwear Altama 425101

- Small Animal Playpen With Mat

- Salicylic Acid For Warts On Face

- Bt999 Earbuds Volume Control

- Mastercool 12 Cfm Vacuum Pump

- Plus Size Teal Jumpsuit

- Maginels Pet Playpen Dog Puppy Crate Kennel Rabbit Fence$15+animaldog

- Utsa Cybersecurity Degree

- Dermablend Foundation Full Coverage

- Small Woodshop Storage Ideas

この記事へのコメントはありません。