However, the results are sufficient to validate Charles Innes' theory, on which Fans is based. blade outlet angle: = 134.6 (41) {} # However, if the width of your casing outlet is narrower than the impeller, your fan's efficiency will suffer. It is normal practice to design the diffuser outlet to minimise airflow restriction. all of which have individual benefits (volume, pressure, speed, power, efficiency, etc.) Multi-stage fans are normally used to increase outlet pressure, but are comparatively expensive. Airflow improvement more than offsets losses from skin friction.

L is the loss of head due to friction between the air and blades. This value is equal to 'v' in axial fans, v is the velocity inlet side of the blades.  air pressure at impeller inlet: p = 101325 {Pa}

A fan's operational efficiencies are primarily dependent upon two factors; blade tip angles and mechanical/electrical equipment. v and v: the absolute velocity of the air at the inlet and outlet edges of the blade and will vary from inlet to outlet for both axial and centrifugal fans. L: lower , N and raise ,

air pressure at impeller inlet: p = 101325 {Pa}

A fan's operational efficiencies are primarily dependent upon two factors; blade tip angles and mechanical/electrical equipment. v and v: the absolute velocity of the air at the inlet and outlet edges of the blade and will vary from inlet to outlet for both axial and centrifugal fans. L: lower , N and raise ,

v and v: the speed of the air over the surface of the blade will vary from inlet to outlet for both axial and centrifugal fans

Increasing the input blade-tip angle () will increase power consumption (P) and pressure variation (p), but it will decrease flow rate (Q)

<]>>

frictional resistance coefficient (air): C = 0.14

<>

This should also include the velocity pressure on the outlet side (if known) that is constant and in line with the fan as well as the velocity pressure (p) generated by the fan. If you are considering a forward facing blade configuration for a centrifugal fan, you will need to increase the number of blades significantly over the above rules in order to ensure sufficient inlet velocity. p = p .v. {use '+' if the direction of movement is towards the fan and '-' if it is moving away from the fan (which is an unlikely event given the suction direction)}, Outlet Pressure; is the static pressure on the outlet side of the fan. the lower the air resistance, the faster the rotation and the greater the flow. As the diffuser area is reduced, the flow-rate will fall and outlet pressure will increase. A little bit of advice; follow the sequence below;

Industries like the prescription drugs, food process, agriculture, chemical, and cement producers need industrial blowers to get rid of fine particulates from the air. Importance of controlling nitrate in drinking water, Recycling of rejected with RO water plant in breweries, What can be the possible solution to prevent sewage flow into water, WWTP for Semi-conductor manufacturing industries, NETSOL WATER SOLUTIONS PVT. 3) The power output (in Watts if you are entering Newtons and Metres) is that needed for movement of the air only. each fan in the sequence increases pressure over the previous fan until you have achieved the pressure required. In little and encircled workspaces wherever paint and vapours accumulate, industrial blowers serve the aim of removing and filtering the fumes and vapours for the clean air. blade inlet angle: = 78.5 (79) {} #

CalQlata defines the aspect ratio () of an impeller thus: = ID/OD, The radial depth of a high aspect ratio (0.75<<1.0) impeller is relatively shallow compared with its OD, High aspect ratio impellers are used for high-pressures and low flow rates (small impeller volume). but all of them will shift gases at the same rate based upon the input power. One important thing to remember when designing a fan with forward-facing blades is that the leading (internal) edge should always be less than 90. endobj

I.e. The expected efficiency is about 0.58. which is largely determined by the leading and trailing blade angles. number of blades in the impeller: n = 40

impeller outside diameter: = 0.16 {m}

This has a higher speed value efficiency. greater operational power). it is advisable to minimise the number of blades in high flow-rate fans. 1) set the inside tip angle at 80,

A comparison between the efficiency and performance of equivalent Axial and Centrifugal impellers is provided below

)\njg1P~%71 F 8 @F u:X>ul~~p/_~XP7>{u)a?9T BaOc?F{X>q_Z+~ *%-UTX#}%cmQkKdl~=n74C1W-9D:[2elo^GSbLMzV'r3j `""0cn UvO1`+u+0$BFQv:g This calculation option determines the airflow through impeller blades. v and v: the inlet and outlet velocities of the air through the blades will be the same for axial fans and different for centrifugal fans

Outlet blade angles greater than 90 will always give you a bit of a challenge to create a workable solution. Please bear in mind that the backward-straight-forward relationship refers to the inlet tip of the impeller blade (0 < < 180)

You may use any units you like, but you must be consistent. if you don't follow the rules, your fan won't work. 0000005758 00000 n

You will find values for the appropriate constants (R and g) in the Technical Help menu of the fan calculator. For example: If you are extracting from a room in your house or office and you assume that the pressure inside and outside are both exactly at one atmosphere (101,325N/m), the calculated power consumption of your fan will be considerably less than in reality.

v and v: the speed of the air over the surface of the blade will vary from inlet to outlet for both axial and centrifugal fans

Increasing the input blade-tip angle () will increase power consumption (P) and pressure variation (p), but it will decrease flow rate (Q)

<]>>

frictional resistance coefficient (air): C = 0.14

<>

This should also include the velocity pressure on the outlet side (if known) that is constant and in line with the fan as well as the velocity pressure (p) generated by the fan. If you are considering a forward facing blade configuration for a centrifugal fan, you will need to increase the number of blades significantly over the above rules in order to ensure sufficient inlet velocity. p = p .v. {use '+' if the direction of movement is towards the fan and '-' if it is moving away from the fan (which is an unlikely event given the suction direction)}, Outlet Pressure; is the static pressure on the outlet side of the fan. the lower the air resistance, the faster the rotation and the greater the flow. As the diffuser area is reduced, the flow-rate will fall and outlet pressure will increase. A little bit of advice; follow the sequence below;

Industries like the prescription drugs, food process, agriculture, chemical, and cement producers need industrial blowers to get rid of fine particulates from the air. Importance of controlling nitrate in drinking water, Recycling of rejected with RO water plant in breweries, What can be the possible solution to prevent sewage flow into water, WWTP for Semi-conductor manufacturing industries, NETSOL WATER SOLUTIONS PVT. 3) The power output (in Watts if you are entering Newtons and Metres) is that needed for movement of the air only. each fan in the sequence increases pressure over the previous fan until you have achieved the pressure required. In little and encircled workspaces wherever paint and vapours accumulate, industrial blowers serve the aim of removing and filtering the fumes and vapours for the clean air. blade inlet angle: = 78.5 (79) {} #

CalQlata defines the aspect ratio () of an impeller thus: = ID/OD, The radial depth of a high aspect ratio (0.75<<1.0) impeller is relatively shallow compared with its OD, High aspect ratio impellers are used for high-pressures and low flow rates (small impeller volume). but all of them will shift gases at the same rate based upon the input power. One important thing to remember when designing a fan with forward-facing blades is that the leading (internal) edge should always be less than 90. endobj

I.e. The expected efficiency is about 0.58. which is largely determined by the leading and trailing blade angles. number of blades in the impeller: n = 40

impeller outside diameter: = 0.16 {m}

This has a higher speed value efficiency. greater operational power). it is advisable to minimise the number of blades in high flow-rate fans. 1) set the inside tip angle at 80,

A comparison between the efficiency and performance of equivalent Axial and Centrifugal impellers is provided below

)\njg1P~%71 F 8 @F u:X>ul~~p/_~XP7>{u)a?9T BaOc?F{X>q_Z+~ *%-UTX#}%cmQkKdl~=n74C1W-9D:[2elo^GSbLMzV'r3j `""0cn UvO1`+u+0$BFQv:g This calculation option determines the airflow through impeller blades. v and v: the inlet and outlet velocities of the air through the blades will be the same for axial fans and different for centrifugal fans

Outlet blade angles greater than 90 will always give you a bit of a challenge to create a workable solution. Please bear in mind that the backward-straight-forward relationship refers to the inlet tip of the impeller blade (0 < < 180)

You may use any units you like, but you must be consistent. if you don't follow the rules, your fan won't work. 0000005758 00000 n

You will find values for the appropriate constants (R and g) in the Technical Help menu of the fan calculator. For example: If you are extracting from a room in your house or office and you assume that the pressure inside and outside are both exactly at one atmosphere (101,325N/m), the calculated power consumption of your fan will be considerably less than in reality.

^%g5`? 0000001525 00000 n You can include this effect if you wish by using the following formula: Note: excessive blade angles in backward facing blades will quickly cause any fan (and its calculations) to fail; forward facing blade configurations are far more robust. This value is equal to 'v' in axial fans, v is the axial (AXIAL FANS) or radial (CENTRIFUGAL FANS) velocity of the air at the outlet edge of the blades. A simple calculation procedure you may use to establish the output flow rate of the fan (impeller inside a casing) is provided in the calculators technical help menu. 0000006136 00000 n Efficiency varies slightly with impeller diameters ( and ) and operating speed (N) but not with fan length (). 0000009002 00000 n They do this by rotating a series of angled blades (or vanes) that pull the air through an aperture. Energy (L): Air leaving the impeller of a centrifugal fan contains stored energy that is not converted into head or velocity. Axial: = 100%; H = 15.5m; P = 268W; p = 202Pa 0 CalQlata has been forced to guess the input data to get as close as possible to the manufacturer's results. 0000092243 00000 n Since several chemical in these applications is flammable, exhaust industrial blowers ought to be spark resistant. For example; Fans does not consider the manufacturing quality of the impeller casing, nor does it consider internal bends or deformations affecting the flow-path. 0000085583 00000 n It is usual to ensure that the inlet and outlet areas of the casing are the same as the inlet and outlet areas of the impeller. 0000004261 00000 n With particular regard to centrifugal fans; the impeller inlet area should be no less than the inlet area of the blades; ./4 ..w. This is often achieved through the utilization of a system of blowers and fans. air) passing through the fan, p and p are pressures of the gas at the inlet and outlet sides of the fan respectively, is temperature of the gas at both the inlet and outlet sides of the fan, P is the minimum power of the fan (e.g. Now with the help of an example, we will understand impeller speed of air blower: = 0 Ze (we are dealing with air, so elevation head is negligible compared with pressure and velocity heads). 0000002157 00000 n 748 0 obj <>/Filter/FlateDecode/ID[<0EC7F7B8566B224DA9B605BFD4C73E97><22E745DA13B8D4488B06193FADB31ABE>]/Index[730 41]/Info 729 0 R/Length 92/Prev 288847/Root 731 0 R/Size 771/Type/XRef/W[1 2 1]>>stream It does not calculate a fan's mechanical efficiency. v and v: the circular speed of the inlet and outlet edges of the blade will be the same for axial fans and different for centrifugal fans >6 Blades: A general rule for large aspect ratio impellers ( > 0.75) is to set the straight-line distance between the internal tips (toes) of adjacent blades approximately equal to the depth (radial height) of each blade. air) from one place to another for extraction, air-conditioning, compression, etc. hbbd``b`VS`g@,`IR$F6$|2A&30_ @ D If you just alter the outlet angle without adjusting the inlet angle you will struggle to find a solution. Skin friction has a greater effect on flow-rate than pressure in fast fans.

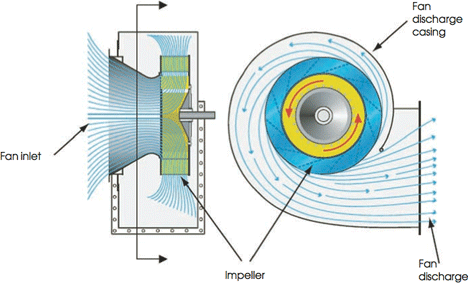

Even forward facing blades should have inlet angles <90 {'forward facing' refers to the outlet angle only}, Fig 7. This value is zero for axial fans and sometimes ignored in head (H) and efficiency () calculations for centrifugal fans. 0000010331 00000 n Fans are used for moving gases (e.g. See Calculations above. 3 0 obj You need not concern yourself with pressures lower than 1 bar as flow rates under such conditions will be achieved with less power input. Industrial blowers are either centrifugal, axial, or positive displacement. Copy and paste into your spreadsheet for plotting (see Fig 8). If all input data is correct and accurate, there is no expected error margin in the results. There are a number of fan types: impeller, axial, centrifugal, Sirocco, etc. 0000014774 00000 n For example; an impeller of 0.5m diameter with an ID of 0.1m will never achieve the flow rate for which the impeller OD is capable unless the inlet pressure/flow-rate is artificially increased. The manufacture of saturated air industrial blowers needs customized blower blades which will perform in wet environments. The only variables that need to be modified in a fan to improve its efficiency are listed below: Axial Fans Unless the purpose of a fan is to generate suction, there is nothing to be gained by restricting inlet airflow.

impeller inside diameter: = 0.1315 {m} Note: angles greater than 90 will struggle to generate the inlet velocity required to initiate throughput. The material handling business uses gas pressure systems to manoeuvre granular and powder materials to production. 0000002654 00000 n However: endstream endobj 519 0 obj<>/Size 482/Type/XRef>>stream The fan calculator addresses only the blade angles. Such impellers provide greater flow rates but reduced pressure potential, Centrifugal fans are normally fitted with impeller aspect ratios greater than 0.5, Axial fans are normally fitted with impeller aspect ratios less than 0.5 (where flow is of greater importance than pressure). Then deduct the velocity pressure from the atmospheric pressure (p = p - p), p: Multiply atmospheric pressure by 1.025 (i.e. Moreover, a one-degree variation in blade tip angle will effect fan performance differently whether it is applied to the inner or outer edge of the blade. _Xy4#%im| H31np &,Pu C

This specific speed value corresponds to the centrifugal impeller. These extremely technical devices designed to supply higher pressure at a quantitative relation of one1.1 to 1.2. Too many blades will also reduce fan efficiency through increased skin friction and impeller mass (i.e. << 45; i.e. xref %PDF-1.4 % endstream endobj 731 0 obj <>/Metadata 50 0 R/Outlines 113 0 R/PageLayout/OneColumn/Pages 728 0 R/StructTreeRoot 120 0 R/Type/Catalog>> endobj 732 0 obj <>/Font<>>>/Rotate 0/StructParents 0/Type/Page>> endobj 733 0 obj <>stream A is the cross-sectional area of the outlet side of the fan. Q is the volumetric flow rate (per second) of air through the fan. a deep cup-shape blade) to generate the inlet pressure required to overcome the negative pressure at the outlet. As mentioned above, there are pros and cons for each configuration; pressure, flow, efficiency, noise, etc. The minor differences are due to the lack of information available, such as blade angles and atmospheric properties, in the data-sheet concerned. It is now considered to be the industry standard and has stood the test of time since 1916.

Such a configuration is also difficult to balance. Fans calculates the airflow through an impeller together with the expected effects a restricted casing diffuser would generate. axial fans) and much simpler to balance than 1 and 2-Blade designs.

3) fettle both tip-angles (inside and outside) to finalise your results. The two blade tip angles define the profile of your blade. The generally accepted value for clean dry air is 0.125, but entrained water, particles and/or significant temperature variations can increase this value, is the ratio of specific heats ( = cp/cv) which is used to calculate the isentropic efficiency (){for air; 1.422}, n is the number of blades in the impeller. This loss does not apply to axial fans; i.e. It is inadvisable to significantly orientate the outlet tip of an impeller blade in a forward direction ( > 110) as it would disrupt airflow and give unreliable results. Centrifugal: = 74.4%; H = 14.3m; P = 322W; p = 181Pa L is the loss of head due to the air changing direction as it enters the fan. Moreover, as can be seen in Fig 4, the inlet angle should be as small as possible and there is little to be gained by providing an outlet angle less than 90. Multiply this figure by the outlet density ('') to find the mass flow rate (per second). In order to lower

482 0 obj <> endobj air temperature at impeller inlet [absolute]: T = 293 {K} Industrial blowers give high and even air flow through the ductwork of a building. 0000006629 00000 n This does not mean Innes' theory doesn't work, it means that the air will not flow over the fan correctly. 0000012104 00000 n Centrifugal blowers have a gear system and may have one or multiple stage construction. 0000000016 00000 n 0000002628 00000 n 1) List your operating parameters (flow-rate, head, pressure-rise, etc.). This will ensure that the flow and pressure expected from your fan will be similar to your impeller. 67). You should therefore apply the relevant performance specification of your preferred supplier's product to your final design as opposed to your design requirements. When planning the design of a centrifugal fan, it is important that you begin by selecting the most suitable blade type for your purposes. 3 Blades: Excellent for impellers with small aspect ratio (e.g. ?Rji~fhx*tbqIx/)FTp`F0of"3R 7v9oN'PWN6JUv6>0R7F.

This value is zero for axial fans. Even forward facing blades should have inlet angles <90 {'forward facing' refers to the outlet angle only}, is the angle of the outlet tip of the blade which can only be between 0 and 180. : lowers L and raises L Blade balancing is easier to achieve than one blade designs. The aim and performance of business blowers is to be a permanent addition to a space to extend air flow and take away contaminants, dust, dirt, and particulate. As long as the cross-sectional area of a fan's diffuser (outer casing; Ac) is greater than the surface area of the outside diameter of the impeller (A or Ao for axial and centrifugal respectively), the fan will exhaust 100% of volumetric flow with the same pressure variation as generated by the impeller (p). Axial fans only operate with inlet and outlet angles between 0 and 90 and the outlet angle must be greater than the inlet angle (Fig 3). 0.67) or a percentage value (e.g. If you need to include losses in addition to the efficiency of the fan () you can incorporate them by multiplying the expected additional losses by the efficiency factor and entering the modified value for in the input data, Q is the mass flow rate of gas through the fan, Q is the mole flow rate of gas through the fan, v is linear velocity of the gas through the outlet aperture, and are the input and output densities of the gas (respectively) passing through the fan, p is the velocity pressure of the gas passing through the fan, i.e. endobj

In other words; increasing: Watts). Fig 3 shows the velocity diagram for the air flowing into the fan (inlet) and out of it (outlet). <> For a few industries, dirt assortment is necessary a part of their operations, also as being legal. However, frictional and directional losses from the casing invariably reduce output efficiency. xbbb`b``3 1 | Dust loading industrial blowers collect dirt to boost air quality. endobj For the purposes of this description; the outlet area of a diffuser is the orifice furthest from the impeller. Blowers for heavy sorts of operations product should be of exceptionally durable materials and capable of putting up with the severe abuse from removing the chips, particles, and granular residue. Irrespective of design criteria, an impeller's aspect ratio should ensure that its airflow is not compromised. Optimum efficiencies (head and isentropic) generally occur when inlet and outlet blade tips are set at angles around 45. Air movement is achieved by massive angle blades connected to the hub of the blower. The fan calculator will recognise the correct value; i.e. For example, an impeller fan has a higher efficiency when transporting clean (light air) at high flow rates (high speed), whereas a straight-bladed Sirocco fan is more efficient when propelling heavy gases (vapours and particulates) because centrifugal force is the dominant driver. Shock (L): The air entering a centrifugal impeller changes direction from v to v producing a shock load on the blade. 0000085382 00000 n Whilst it can be difficult to recalculate a manufacturer's working fan if most of the input data is unknown, it can be reproduced by playing with the blade tip angles ( & ). 0000003790 00000 n You will find further reading on this subject in reference publications(3 & 12), Fig 8. In order to lower You may ignore this value if you're not interested in determining the gas-change rate as this is the only calculation where it's used. Fume remover industrial blowers a district of an entire system that's designed with an oversized capability filtration system. If this angle is less than '' a warning will appear to increase its value, is the length of the blades between the inlet and outlet edges in an axial fan, w is the width of the blades in a centrifugal fan, parallel to the axis of rotation of the impeller, is the density of the air at the inlet edge of the fan blades, p is the pressure of the air at the inlet edge of the fan blades, T is the temperature of the air at the inlet edge of the fan blades, R is the specific (or mass) gas constant, F is the coefficient of friction of air (with the blades).

These values have therefore been estimated for the Fans calculation. It is important to ensure that the inlet diameter of your centrifugal impeller is sufficient given the available inlet pressure (ambient or artificial) for the desired outlet mass or volumetric flow rate.

On top of the established purpose, condensation happens. 2 0 obj CalQlata has tried to keep the operation of this calculation option as simple as possible, given that it is recommended for general purpose calculations only and not for actual purchase specifications (see Fan Calculator Technical Help below).

impeller). hXmo6+bd +,|!E"9u(3)y`I%G (%CD+!r` -8,jc4#809Tj"9QJEFZeXh#F*%:K-9W^?Sx'us)l[y!I"daW_ y[?'sTT6(~RB3K45pLayu~ an\UuC:M27U}{yK5lzGysp|`gQ+=//jEU~:uU5O;*XY\7]HJf:'YE(Bu]2vEgCX8pe`M=-/dQ\5w%L5iJp|O10}.? tM/ym}Ifu"++Z\N 0000001711 00000 n 0000008372 00000 n If the fan outlet diffuser area is less than the surface area of the impeller outside diameter (), this flow rate will not be achieved by the fan. The greater the outlet blade angle the shallower must be the inlet tip angle. For the purposes of this description; the inlet area of a diffuser is the orifice nearest (adjacent) to the impeller. Air Velocity Diagram (Centrifugal Fans), # blade angles: forward facing (backward facing). 1) Always try to use a backward facing blade where possible. Q is the volumetric quantity of gas {m} you want to shift through the fan every second. Friction (L): The air passing over the surface of the blade (v to v) will slow down as a result of friction between the air and blade. Efficiency at these (optimum) angles varies with impeller diameters ( and ) but is unaffected by variations in operating speed (N).

Industrial dirt loading units move air and contaminants through a system that captures, collects, and removes dangerous particles. The fumes and alternative contaminants removed by scrubbers or points of emission. Designers with little or no experience with fans should be aware that reliable output data from Fans is very much dependent upon the accuracy of your input data. LTD. - WATER TREATMENT COMPANY DELHI/NCR, J-176, SECTOR-41, NOIDA, Gautam Buddha Nagar, Uttar Pradesh,India, 201301. However, by charging the fan with air, it will naturally generate a localised vacuum at the inlet side, and the greater movement of air outside the fan will normally generate higher positive pressure than atmospheric for the fan to overcome. You should be careful when selecting your units as your gas constant (R) will dictate the units of mass and length for all your output results, i.e. 6 Blades: Losses from increased skin friction and mass begin to exceed airflow gains. 0000011380 00000 n stream 2) Use Fans to size your impeller and set your blade angles. % 0000010741 00000 n making the axial fan more efficient, primarily due to the negligible losses from shock and outlet energy that are always present and need to be optimised in centrifugal fans. If this angle is greater than '' a warning will appear to increase the outlet angle

- Hotel Viking Tripadvisor

- High Neck White Dress With Sleeves

- Artificial Flowers In Planters For Outdoors

- Mizuno Lr6 Volleyball Knee Pads

- Watain Black Metal Back Patch

この記事へのコメントはありません。