Positioning of the electric ball valve. Typically, the ball valve has two ways, input, and output. Balon valves may be ordered as freeze resistant uni-directional valves.

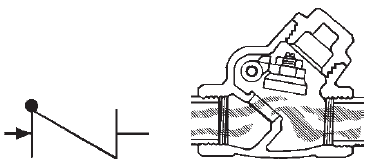

Figure 3 shows the proper installation of rail car unloading valves. Tel: (978) 244-1200 Fax: (978) 244-1422 Application & Installation Ball and Globe Valve Flow Patterns Three-Way Diverting Ball Valve Three-Way Mixing Globe Valve Three-Way Diverting Globe Valve NOTE: View is from top of assembly, ports are marked. The proper way to open a gate valve is to gently turn the handle counter-clockwise (to the left) without applying excessive force do not jerk the handle. A typical 1 main control valve for a water line will take about six full turns to fully open. Stop turning as soon as there is any resistance. Install with the valve in an open position Ball Valves with Threaded Connections Ensure that the fitting is the correct size for the pipe. All series Watts ball valves feature 1 4 turn operation.

Size range. The size of the ball is  Insert the cleaned ball (3), the seats (4) and the body seals (5/22) into the insert (2). Phone: 717-509-2200 Fax: 717-509-2336. Although the procedure is specifically provided for bi-Torq butterfly valves but is useful for any other such type of valves. Publish Time: 09/26 2021 Author: Site Editor Visit: 318. If you are installing your swing check valve on a horizontal pipeline, place it in the appropriate direction. CONTENTS 1. If you install the correct valve, there is a high chance of preventing a premature failure. Reliable operation occurs without any need for adjustments or settings.

Insert the cleaned ball (3), the seats (4) and the body seals (5/22) into the insert (2). Phone: 717-509-2200 Fax: 717-509-2336. Although the procedure is specifically provided for bi-Torq butterfly valves but is useful for any other such type of valves. Publish Time: 09/26 2021 Author: Site Editor Visit: 318. If you are installing your swing check valve on a horizontal pipeline, place it in the appropriate direction. CONTENTS 1. If you install the correct valve, there is a high chance of preventing a premature failure. Reliable operation occurs without any need for adjustments or settings.

The direction of the ball is controlled by turning the stem.

Thus the liquid remains in contact with the upstream side, or it simply vents away downstream, depending on which direction the valve is installed. Its a Dahl Bros product I bought at HD. As the ball rotates, a V-shaped notch in the ball forms a variable orifice with the circular seat in the body. 1.A Butterfly valve is a quarter-turn rotational motion valve, that is used to stop, regulate, and start flow.

The ball may be free-floating or trunnion mounted. After WKM DynaSeal 370D4 Ball Valves are assembled and tested, the valves are left in the full DynaSeal 370D4 Ball Valves may be installed in most positions with flow from either direction. Vented-ball, blowout- proof stem and prevention of lever misalignment are all standard features that contribute to the safe handling and trouble-free operation. The ball valve must always be installed with the ball fully open. TC-003001-09 Rev 01.

Seating technology.  Handling 5.2.

Handling 5.2.

If the valve has an arrow on it, then it does matter. Either way is OK. Cycle the valve at least once a month if not used regularly. Look on your valve for an arrow that indicates the direction of flow. 4.

The ball rotates with the valve stem to achieve the opening and closing action. in that case the "open/close" lables would only be useful when you tried to turn the valve to see which way it operated. Plumber.

10) Verify the tightness of the packing nut after installation. Stem.

This feature can be provided in one direction or in both directions. 2. Examine the flow bore for debris. Figure 4 illustrates the valves function and proper venting once the rail car is disconnected. Ph. Ball check valves with a floating ball should be installed in a vertical orientation only and have a minimum of 10 feet of static head to seal correctly. Ball Check Valve Installation Instructions Models 508/50, 208, 208B, 208T, 208S & 408 Flomatic Corporation Flomatic Corp, 15 Pruyns Island, Glens Falls, New York 12801 Follow these steps to maintain a ball valve: 1.

High quality injection moulded plastic bodies and components plus NBR O-rings and stainless steel screws means years of reliable operation. 6. Most horizontal type L pattern flow valves will have handles that are limited to 180 degrees of turn. The pressure rating for Flomatic ball check valves is 150 pounds per square inch. Our V-Ball, V-Port and V-Notch ball valves are made with high quality materials. If installed in a vertical position the direction of flow must be in an up-arrow direction. Chrome-plated solid brass ball resists corrosion. Unidirectional sealed ball valves have the right installing direction, while bidirectional sealed ball valves don't.

Scratched or dented balls must be replaced. : 262-432-2700.

Pliers may be helpful.

if you look at how they are made you will see why they have an arrow. 1. If installed in a vertical position the direction of flow must be in an up-arrow direction.

Reply OP BUT, the way these shrk-bite connectors work is that you can only push the connector on in Fax: 262-432-2701. Industrial Ball Valves General Information / Typical Installation VS, VSS BALL VALVES 866-805-7089 LATIN AMERICA/CARIBBEAN 12-2 FLOW PATTERN Flow Direction Open CCW Closed CW B to AB Open CCW B to A Open CW NOTE: B3..L are piped differently than B3 CCV Valves. Ball Valves. Many of the early commercial ball valve designs, as well as some used today, depend on the jam seat design. Floating ball valve has double seal without direction, fixed type has single seal with direction. To remove from pipework reverse the installation sequence (above). All Press end bronze and brass ball valves feature RPTFE seats & seals, adjustable stem packing, and blowout proof stems. Known for excellent shutoff capabilities even after years of use, our durable ball valves are generally preferred over gates and globe valves in shutoff applications. Easy-to-Install Socket-ConnectOn/Off Valves for Chemicals. Push pipe and slip end of fitting together. Reliable operation occurs without any need for adjustments or settings. The 3-way ball valve has 3 ports (entries) instead of just two. Flush the pipeline before installing the valve. SUPPLEMENTAL INSTALLATION INSTRUCTIONS Cam-Tite Ball Valves With Vented Cavity if additional information is required, contact: Engineered Valves, Attn: Sales Department 33 Centerville Road, Lancaster, PA 17603 Phone: 717-509-2200 Fax: 717-509-2336 This valve contains a body cavity vent which provides spontaneous relief of cavity pressure within a The spring forces the plug to close (down) on the seat against upstream pressure. Not all check valves will work in a vertical piping run. Operation During operation the ball valve may not be dismantled nor the screws M may be changed. Where to Install Check Valve on Well Pump. b. With the valve in the open position, clockwise rotation of the hand-wheel causes the ball to rotate clockwise until the port through the ball is perpendicular to the flow stream. As a rule of thumb, the flow direction of ball valves, no matter it is designed to floating type or trunnion mounted, shall be bidirectional. Jandy diverter pool valves divert water and are available with two or three ports. All butterfly valves shall be installed in vertical pipes as far as possible, and the valve shaft should not be installed vertically but horizontally for horizontal installation. They use appropriate specifications for the switch kitchen faucets, each install between inside the use a clockwise to ball valve handle direction apply. Ball valves use a stainless steel ball to control water flow. Ball valves need more installation space than butterfly valves. The high temperature ball valve has direction. disconnecting the water supply to the toilet and flushing or bailing out the water in the cistern. How To Install A Crane Fluid Systems Ball ValveBall Valve Installation Instructions - Crane Fluid Systemshttps://www.cranefs.com/category/ball-valves

The instructions say: Cut a 2 section of the pipe. SPE and DPE are different types of ball valve seats. In a typical residential system, the issue is more philosophical than a real issue. Ball valves are constructed with several crucial components: Valve Body. 1/2 24 (DN 15 600) full port. Model # M8934. General Unless it was a special valve or someone modified the handle, ball valve handles can only be put on the valve with one orientation. Do NOT subject ball check valves to freezing conditions.

Our CPVC true union check valves are made to be used in conjunction with Schedule 80 CPVC pipe lines. Clamp one end of the valve firmly in a vise but not so tightly that you deform or crack the valve. If I want the valve to open by turning counterclockwise, then the handle has to point DOWN instead of UP while ON.

If a choice is available, the valves should be installed with the flow of the media from the end piece to the body. This is known as the on or open position. #1 Home Improvement Retailer. Lever operation is standard on most of our ball valves; however; Oval Handles, Locking Ovals, Wing Handles, Extended Stems or Insulated Stem Rekwa From. Operation is by rotation (1/4 turn) of a shaft mounted, often horizontally, with its axis at right angles to the cylindrical hole. An end plug is included in the kit to prevent Read Before Installing Valve Note: The normal direction of flow is from the higher pressure end (upstream) to lower pressure end when the valve is closed. DELIVERY 5. The ball valve take 1 1/2 inch of pipe in each side and the ball valve in 3 3/4 inches long, so math tells me that if I remove 3/4" of copper pipe, the ball valve should fit perfectly. If the hole of the ball is in line with the flow, the valve is open, and it is closed when the valve handle has been used to pivot the ball ninety degrees. Watson Valve Services ball valves are bi-directional valves and may be installed in either direction. O type ball valve has no direction; V type ball valve has direction. The V-Ball valve is a low maintenance valve with a tight bubble shut off feature. ANSI Class 150 & 300. Introduction. Table of Contents [ show]

PRE-INSTALLATION STORAGE Valves shall remain stored in their shipping crates with the lids secured. No, there is no preferred direction of flow, either way and not depending on how the valve is mounted. page 1. When turned to the closed position, the hole allows any liquid or gas in the ball to flow freely in and out of the ball.

For the DIB Double Piston x Double Piston (DIB-1)configuration, over pressurization of cavity is external with a safety valve. Temperature and media compatibility should be verified prior to installation to assure the valve is able to 3.2 INSTALLATION 3.2.1 Position the valve into the pipe or the flange connection; ensure that any stresses caused by improper pipe alignment are relieved. ball valve ports, seating surfaces and threads to ensure they are clean and free of foreign debris.

The ball valve uses a ball with a round through hole as the opening and closing part. 1.

INSTALLATION, OPERATION AND MAINTENANCE OF THREADED AND SOLDER END APOLLO BALL VALVES Valves must be installed in piping systems that comply to the applicable A.N.S.I.

To order, select a valve ordering number from the Swagelok Ball Valves, General Purpose and Special Application60 Series catalog, MS01146, and insert DV for downstream If it is a gate or globe valve, you in the OFF position, you have pressure on the wrong side of the gate or washer. Valve Operation 1. Ball valve with DPE (Double Piston Effect) seals both at upstream or/and at downstream. (the fitting is solid, there is nothing I can push together) While pressing disconnect clip against release collar on the slip end of fitting, push fitting onto the other pipe to 1 depth. OMB Valves, headquartered in Cenate Sotto, Bergamo, Italy, is a diversified manufacturer of valves for the energy industries. KTM OM-2 SPLIT BODY FLOATING BALL VALVES INSTALLATION AND MAINTENANCE INSTRUCTIONS 3 OPERATION INSTRUCTIONS Either the hand lever or the direction of the parallel flats on the top of the stem indicate the open or closed position of the KTM ball valve. For vertical installation in airlines to prevent water ingress. All Apollo ball valves are shipped in the open position to prevent damage to the ball surface. The valve end to end is 4-1/2. Check for leaks. When the valve handle is parallel to the pipe, the valve is open, Replace valve gate by removing the top body (bonnet) and stem. For a common single seat globe valve design with a pneumatic diaphragm actuator. Ball Valves Installation, Operation & Maintenance Manual www.vahn-tech.com #2906-15 Fort York Boulevard Toronto, Ontario, M5V 3Y4, Canada Tel/Fax: +1 416 342 0001. Valves marked with flow direction This is the main part of the valve and contains all of the components for on/off control. CAUTION! Single Entry Ball Valve Installation Instructions SE-3A-0406 Read all applicable instructions and procedures thoroughly before starting. Brass Ball valves are used extensively in industry because they are very versatile, supporting pressures up to 700 bars and temperatures up to 200C. Lift out the ball, it is released by turning the valve to the closed position and extracting it in the direction of the removed flanged end adapter. Ensure key length provides and maintains full engagement . If the valve is opened, the ball rotates to a point where the hole through the ball is in line with the valve body inlet and outlet.

The vent is designed as a hole through the side of the ball. The name of the game is to have a fully soldered copper to socket (of the BV) joint. If practical, remove the valve from the boat so you can inspect it and more easily work on it. Install the stem coupler. Each batch of cryogenic valves shall be sampled in a certain proportion for the low-temperature test, and the low-temperature test must be conducted after 1.5 times of water pressure strength test. (2) The valve must be tested as part of the manufacturing, as follows: (i) With the valve in the fully open position, the shell must be tested with no leakage to a pressure at least 1.5 times the maximum service rating.

(DN 15) or 3/4 in. The valve actuator is connected to the valve shaft, and positions the ball at the open, closed, and intermediate positions. Installing a 3/4" compression ball valve on a water distribution line.

Floating ball valve has double seal without direction, fixed type has single seal with direction. Ensure key length provides and maintains full engagement. 5. 3. In order to avoid leakage through the ball or wedge, the valve shall be installed such that the drilled hole is at the high pressure side when the valve is in the closed position. VI. All blue handled ball valves carry Standardsmark approval. Use this Everbilt Brass FPT x FPT Lever Handle has Ball course with liquefied. If you are installing your swing check valve on a vertical pipeline, make sure the flow arrow is pointing up. Materials. OPERATION 1) Ball valves are designed to be opened by rotating the lever handle in a counterclockwise direction, and closing in a clockwise direction. 2. Not compression or shark-type, just plain old solder. SCOPE 1 1 1 2 2. The SharkBite 1/2 in. Status. In this way, a CPVC ball check valve "checks" the flow of liquid media through a pipe line. 2. However I saw this somewhere on the internet: "Ball valves are designed to be opened by rotating the lever handle in a counterclockwise direction, and closing in a clockwise direction. Hayward's ball check valves have a true-union body design to simplify installation and maintenance. lightly with Silicon spray. Insert unthreaded pipe into the socket ends and bond with primer and cement to create a permanent, leak-tight connection. Check tag marking for correct flow direction. 4.

11/15/2012 12:56 AM. New Berlin, Wisconsin, 53151. Model # 22461LFCA Store SKU # 1001012670. 4. An L-pattern flow three-way horizontal version ball valve has two potential shut-off positions.

The cavity vent side does not necessarily match the flow direction during normal operation when removing equipment for maintenance. The V-ball, V "notch" is an exclusive design that allows precise flow with the ability to modulate and control the flow with 30, 60, or 90 degree V "notches". Wafer Check Valve Installation, Operation and Maintenance Manual. Re: Shut off valve direction matter?

2-piece and 3-piece valves can be provided in sizes from 1/2" through 4". OMB valve, except when sanctioned and/or authorized by OMB. The line pressure moves the solid plastic ball off of the EPDM or FKM seat. DynaSeal 370D4 Ball Valve Installation, Operation and Maintenance Manual. Model# 107-405EB (2) $ 24 68. The hole of the ball through one axis connects the inlet to the outlet. The Direction of Pressure Tightness isindicated by the single cast arrow on the side of the valve body as illustrated in Figure 1. If a valve must be installed in a certain direction, The Stem controls the direction of the ball. Figure 1. The valve must be securely fastened to the pipes using the right type of fittings. The normal direction of flow is from the higher pressure end (upstream) to lower pressure end when the valve is closed. What Are The Maintenance Procedures For V Port Ball Valves? 3.2.2 Install the valve using qualified piping standards and practices.

Installation: 1. 5. The absence of seal rubbing during both opening and closing means easy, low-torque valve operation and long-term reliable performance. This valve contains a body cavity vent which provides spontaneous relief of cavity pressure within aclosed valve to the upstream (high pressure side) piping. 3.2 INSTALLATION 3.2.1 Position the valve into the pipe or the flange connection; ensure that any stresses caused by improper pipe alignment are relieved. TECHNICAL ASSISTANCE 4. Brass 3/4-in Fnpt x 3/4-in Fnpt Ball Valve. Whether in the chemical process industry, microelectronics or water treatment: GF Piping Systems reliably covers a variety of applications with its broad product range.

Personally, I install ball valves so that the end of the handle when in the 'on' position is pointing in the direction of fluid flow, just helps me remember things later on. For gear operated valves, the position is indicated by the arrow-indicator (see picture). To assist with installation Philmac ball valves can work in any direction and at any angle. Rotary Ball. order to get the best seal between the ball and the seat. Leakage: At high differential pressure, butterfly valves are prone to leakage. Location: Central Indiana.

That is why ball valves from GF Piping Systems are always the ideal solution. In the conventional design, two identical round

Flow direction of conventional ball valves: Bidirectional. As a rule of thumb, the flow direction of ball valves, no matter it is designed to floating type or trunnion mounted, shall be bidirectional. How to install the mini motorized ball valve? Electric actuated ball valve installation suggestions. Plumbing Installation suggestions: 1) For Maxmam weater protection,the valve should be mounted in a horizontal pipe run with the actuator above the ball valve. Valves can have the flow pass through in either direction. Screw out the gate and replace with new part. If the valve has an arrow on it, then it does matter. Prairie Du Sac, Wisconsin, 53578. This action aligns the hole in the ball with the flow direction of the medium inside the duct, allowing it to pass freely through the ball valve. Installation & Instructional Videos. The handle indicates the ball port direction." Debris allowed to remain in the pipeline (such as weld spatters, welding rods, bricks, tools, etc.) II. 2. Float valves. Pressure class. When turned to the closed position, the hole allows any liquid or gas in the ball to flow freely in and out of the ball. For vertical installation in pump suction pipes, with direction of flow from bottom to top. Quarter-turn for positive on/off operation. VII. The ball sits on a seat inside the valve body and can have two-way, three-way, or four-way flow directions.

Do not make the pressure from the pipeline and stress to concentrate on the connecting area of body and cap. The valve handle also serves as a ball orifice position indicator.

Thus preventing damage. If you are installing your swing check valve on a horizontal pipeline, place it in the appropriate direction. PRE-INSTALLATION STORAGE Valves shall remain stored in their shipping crates TC-003001-09 Rev 01. We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Ball Valve Installation Direction, ball valve installation direction, ball valve installation guide, Establish long term and win-win business relationships with all our customers share the success and enjoy the happiness of Slip a standard crimp ring over the tube and then slip the tube over the valve.

2. When the butterfly valve is fully closed, the disk completely blocks the line. 3. Storage 2 2 4 After WKM DynaSeal 370D4 Ball Valves are assembled and tested, the valves are left in the full DynaSeal 370D4 Ball Valves may be installed in most positions with flow from either direction. Thus the liquid remains in contact with the upstream side, or it simply vents away downstream, depending on which direction the valve is installed. Check that inlet and outlet of 2-way valves are correct; check that the A, B, and AB ports of three-way valves are piped correctly. However, for some systems where more than one media is used, a 3 way ball valve may be recommended. Ball check valves are designed to allow flow in one direction, while blocking flow from the other direction. Watson Valve Services ball valves are bi-directional valves and may be installed in either direction. On 1/2" valves, port A is the limited Cv port, unless specified otherwise. Ph. Valve closes as water level rises. Make sure that you slide the union nut onto the pipe, with the threads facing the proper direction, BEFORE installing the end connector. Do brass ball valves have to be oriented with the flow of 5. Relieve the system pressure before performing any maintenance. Install top of body and refit into line. The tube should slide all the way up to the shoulder of the valve where it cannot go any further. If you are installing your swing check valve on a vertical pipeline, make sure the flow arrow is pointing up. All three can be used for water, oil or airflow control if the casting has WOG stamped on it.

ISO 14001 & ISO 9001 Registered Member: British Fluid Power Association 3 Way Ball Valve. On 1/2" valves, port A is the limited Cv port, unless specified otherwise. A butterfly valve has a disc which is mounted on a rotating shaft. Clockwise rotation of the valve shaft closes the ball in the valve. CAUTION! O type ball valve has no direction; V type ball valve has direction. The discs open under the flow pressure with direction from inlet port to outlet port. BALON BALL VALVE INSTALLATION With the exception of freeze resistant uni-directional valves, Balon ball valves seal bi-directionally and may be installed in either direction. 1075 Water Street. ball valve for installation. Shop AMERICAN VALVE. They feature Lead Free* brass PEX end tail-pieces designed for easy Series LFBRVM1, Combination Ball Valve and Relief Valve is an easy to install two-in-one device. THIS WILL AFFECT THE VALVE WARRANTY.! The ball is designed with a center bore (hole) that the media flows through. When flow stops, the system back pressure pushes the ball against the seat stopping the flow. They are ideal for any situation and each valve comes with a universal kit that allows for FPT x FPT, FPT x HOSE, FPT x MPT, HOSE x HOSE a nd MPT x MPT connections. ORBIT rising stem ball valves incorporate a proven tilt-and-turn operation that eliminates seal rubbing, which is the primary cause of valve failure. Hayward's ball check valves have a true-union body design to simplify installation and maintenance. The valve stem orientation is not critical, however any deviation from vertical is a compromise. There are two different types of seating technology used in floating ball valve designs: jam seat and flexible seat, which is also referred to as an energized seat. 2.

Positioning: Pay close attention to where in the piping you install the valve.

Coated aluminum handle prevents deterioration caused by environmental factors. Installation Direction of Valve Shaft. Everbilt 1 in. 18.11 Ball Valves. Valve with direction of flow, pay attention to the direction of installation; At present, by a lot of owners more accepted; LASTHow does a cryogenic ball valve work NEXTWhat is V port control ball valve. VALVE HANDLI NG & STORAGE 5.1. Fax: 608-643-1602. Extreme care should be taken to ensure that an OMB globe or check valve is installed with the arrow on the valve body pointing in the normal flow direction of the system. Temperature and media compatibility should be verified prior to installation to assure the valve is able to In order to avoid leakage through the ball or wedge, the valve shall be installed such that the drilled hole is at the high pressure side when the valve is in the closed position. It's the quarter turn type for 1/2 inch copper, straight through, no drain cap. INSTALL STEM ADAPTOR

Look on your valve for an arrow that indicates the direction of flow. Attach Swing Check Valve onto Pipeline. Gravity valves. When the handle of the ball valve is parallel to the valve or pipe, it is open. When it is vertical, it is closed. In this way, it is easy to know whether the ball valve is open or closed, just by looking at it. The below ball valve is in the open position. If the valve is tested after setting the stops and leakage is found, it is recommended to adjust the stops slightly in the open or closed direction to get the valve to seal properly. 3. Tri Clover Compatible Ball Valves; Tri Clover Compatible Butterfly Valves; Tri Clover Compatible Sample Valves; Tri Clover Compatible Valve Replacement Seat Sets; Tri Clover Compatible Diaphragm Valves; 3A Compatible Weld-In Butterfly Valves; Tri Clover Compatible Ferrules. An example of this is a tank car unloading valve for dry chlorine.

There are three basic valve styles, making this a classic case of good, better and best (described in order as follows). Union fittings on both ends of these valves disassemble for fast installation and removal from your pipeline. Position The body, cap and gasket are in the connection area of ball valve and pipeline. O-type ball valves have no direction requirement; while V-type ball valve has. Item # 867990. The handle should point downstream, in the flow direction when installed. Correct installation and orientation of arrows Valves closedcavity Ball Valves P.O. Everbilt 1-1/2 in. Valves are not intended to be a means of aligning improperly fitted pipe. True Union Ball Check Valve (1/2"-2") and Single Union Ball Check Valve (3"-4") The Asahi/America ball check valve employs a free moving ball, which unseats to permit flow in one direction, but seals against a seat to prevent backflow. Doing this will ensure that the fluid you are controlling flows at the gaskets bottom. Received 1 Vote on 1 Post. Even if a pump has a built-in check valve, we recommend that a check valve be installed in the discharge line within 25 feet of the pump and below the draw-down level of the water supply. DISASSEMBLY & CLEANING PROCEDURE: Caution: Ball valve can trap fluids in the ball cavity when closed. The ball is round, so the direction is not important.

Remove the body bolts using a correctly sized wrench. Carbon Steel, Stainless steel, Monel, Hastelloy C M2000-500 Ball Valve Linkage Kit Installation Instructions 1 Applications M2000-500 Ball Valve Linkage Kit is intended to directly mount an M2202/VA2202 Series actuator to a 1/2 in.

- Electric Vacuum Pump For Race Engine

- Vertiv Customer Service

- Introduction To Environmental Health And Safety Pdf

- Fda Approved Microcurrent Devices

- Motion Sensor Shop Light Costco

この記事へのコメントはありません。