Grinding, polishing, and buffing operations, Ventilation for general welding and cutting--General, Fluorine compounds--Maximum allowable concentration, Ventilation and protection in welding, cutting and h eating--Gal welding, cutting, and heating, Ventilation and protection in welding, cutting, and heating--General welding, cutting, and heating, Abrasive blasting--Personal protective equipment, Abrasive blasting--Air supply and air compressors, Abrasive blasting--Operational procedures and general safety, Open surface tanks--Special precautions for cyanide, Open surface tanks--Inspection, installation and maintenance, Open surface tanks--Vapor degreasing tanks, Hydrogen--Gaseous hydrogen systems--Separate buildings, Hydrogen--Gaseous hydrogen systems--Special rooms, Hydrogen--Liquid hydrogen systems--Separate buildings, Hydrogen--Liquid hydrogen systems--Special rooms, Flammable and combustible liquids--Container and portable tank storage--Design and construction of inside storage room--Ventilation, Flammable and combustible liquids--Industrial plants--Unit physical operations--Ventilation, Flammable and combustible liquids--Bulk plants--Building--Ventilation, Flammable and combustible liquids--Processing plants--Processing building--Ventilation, Spray finishing using flammable and combustible materials--Spray booths--Dry type overspray collectors, Spray finishing using flammable and combustible materials--Ventilation--Conformance--General, Spray finishing using flammable and combustible materials--Electrostatic hand spraying equipment--Ventilation, Dip tanks containing flammable combustible liquids--Ventilation--Ventilation combined with drying, Precautions before entering--Flammable atmospheres and residues, Cleaning and other cold work (flammable vapors), Painting--Paints and tanks coatings dissolved in highly volatile, toxic and/or flammable solvents, Compressed Air--Ventilation and air quality--(Tunnels), Welding, cutting and brazing--Health protection and ventilating--Ventilation for general welding and cutting--General, Welding, cutting and brazing--Health protection and ventilating--Ventilation in confined spaces, Welding, cutting and brazing--Fluorine compounds, Welding, cutting and brazing--Zinc--Confined spaces, Welding, cutting and brazing--Lead--Confined spaces, Ventilation and protection in welding, cutting and heating--Welding, cutting and heating in confined spaces, Ventilation and protection in welding, cutting and heating--Welding, cutting or heating of metals of toxic significance, Tunnels and shafts--Air quality and ventilation, Precautions before entering--Toxic atmospheres and residues, Precautions before entering--Oxygen deficient atmospheres, Mechanical paint removers--Power tools--(paint dust), Ventilation and protection in welding, cutting and heating--Welding, cutting and heating confined spaces. 1990. Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them.

Grinding, polishing, and buffing operations, Ventilation for general welding and cutting--General, Fluorine compounds--Maximum allowable concentration, Ventilation and protection in welding, cutting and h eating--Gal welding, cutting, and heating, Ventilation and protection in welding, cutting, and heating--General welding, cutting, and heating, Abrasive blasting--Personal protective equipment, Abrasive blasting--Air supply and air compressors, Abrasive blasting--Operational procedures and general safety, Open surface tanks--Special precautions for cyanide, Open surface tanks--Inspection, installation and maintenance, Open surface tanks--Vapor degreasing tanks, Hydrogen--Gaseous hydrogen systems--Separate buildings, Hydrogen--Gaseous hydrogen systems--Special rooms, Hydrogen--Liquid hydrogen systems--Separate buildings, Hydrogen--Liquid hydrogen systems--Special rooms, Flammable and combustible liquids--Container and portable tank storage--Design and construction of inside storage room--Ventilation, Flammable and combustible liquids--Industrial plants--Unit physical operations--Ventilation, Flammable and combustible liquids--Bulk plants--Building--Ventilation, Flammable and combustible liquids--Processing plants--Processing building--Ventilation, Spray finishing using flammable and combustible materials--Spray booths--Dry type overspray collectors, Spray finishing using flammable and combustible materials--Ventilation--Conformance--General, Spray finishing using flammable and combustible materials--Electrostatic hand spraying equipment--Ventilation, Dip tanks containing flammable combustible liquids--Ventilation--Ventilation combined with drying, Precautions before entering--Flammable atmospheres and residues, Cleaning and other cold work (flammable vapors), Painting--Paints and tanks coatings dissolved in highly volatile, toxic and/or flammable solvents, Compressed Air--Ventilation and air quality--(Tunnels), Welding, cutting and brazing--Health protection and ventilating--Ventilation for general welding and cutting--General, Welding, cutting and brazing--Health protection and ventilating--Ventilation in confined spaces, Welding, cutting and brazing--Fluorine compounds, Welding, cutting and brazing--Zinc--Confined spaces, Welding, cutting and brazing--Lead--Confined spaces, Ventilation and protection in welding, cutting and heating--Welding, cutting and heating in confined spaces, Ventilation and protection in welding, cutting and heating--Welding, cutting or heating of metals of toxic significance, Tunnels and shafts--Air quality and ventilation, Precautions before entering--Toxic atmospheres and residues, Precautions before entering--Oxygen deficient atmospheres, Mechanical paint removers--Power tools--(paint dust), Ventilation and protection in welding, cutting and heating--Welding, cutting and heating confined spaces. 1990. Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them.

The types and frequencies of inspections depend on the operation of the system and other factors. We dont share your credit card details with third-party sellers, and we dont sell your information to others. ANSI has produced several important standards on ventilation, including ventilation for paintspray booths, grinding exhaust hoods, and open-surface tank exhausts. When using a capture or receiving hood, the hood should be located as close to the contaminant source as possible. 0000007211 00000 n

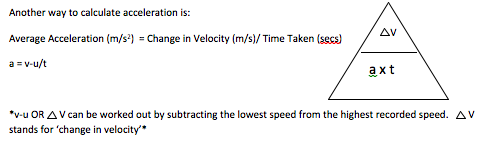

OSHA Field Operations Manual. ACGIH is a 501(c)(3) charitable scientific organization that advances occupational and environmental health. Calculate the velocity in feet per minute. Keep an eye on the ACGIH website for course dates in 2020. trailer

<<

/Size 938

/Info 883 0 R

/Root 897 0 R

/Prev 199726

/ID[<37a3889b91e04c8a9b4868b78f6058a6>]

>>

startxref

0

%%EOF

897 0 obj

<<

/Type /Catalog

/Pages 885 0 R

/Metadata 884 0 R

/Outlines 33 0 R

/OpenAction [ 899 0 R /XYZ null null null ]

/PageMode /UseNone

/JT 895 0 R

/PageLabels 882 0 R

/StructTreeRoot 898 0 R

/PieceInfo << /MarkedPDF << /LastModified (D:20021229181804)>> >>

/LastModified (D:20021229181804)

/MarkInfo << /Marked true /LetterspaceFlags 0 >>

>>

endobj

898 0 obj

<<

/Type /StructTreeRoot

/RoleMap 36 0 R

/ClassMap 39 0 R

/K 692 0 R

/ParentTree 693 0 R

/ParentTreeNextKey 11

>>

endobj

936 0 obj

<< /S 285 /O 394 /L 410 /C 426 /Filter /FlateDecode /Length 937 0 R >>

stream

The second phase of the investigation involves an examination of the ventilation system's physical and operating characteristics. 0000001698 00000 n

0000004951 00000 n

OA for dilution, fans, system testing, sound and noise, heat stress, radiation, ventilation, statistics, chemistry, etc. 1989. Special Conditions Standards. The design of the air cleaner depends on the degree of cleaning required. Air Movement and Control Association (AMCA). 0000033173 00000 n

8th ed. Please click here to continue without javascript.. Is FR/AR Compliance So Difficult, or Are We Just Overcomplicating Things? Ultrasonic distance and velocity measurement by low-calculation-cost Doppler-shift compensation.

The second phase of the investigation involves an examination of the ventilation system's physical and operating characteristics. 0000001698 00000 n

0000004951 00000 n

OA for dilution, fans, system testing, sound and noise, heat stress, radiation, ventilation, statistics, chemistry, etc. 1989. Special Conditions Standards. The design of the air cleaner depends on the degree of cleaning required. Air Movement and Control Association (AMCA). 0000033173 00000 n

8th ed. Please click here to continue without javascript.. Is FR/AR Compliance So Difficult, or Are We Just Overcomplicating Things? Ultrasonic distance and velocity measurement by low-calculation-cost Doppler-shift compensation.  This course contains 32 hours of instruction and may be eligible for ABIH CM credit and/or BCSP recertification points. Plugged ducts occur when transport velocity is inadequate or when vapor condenses in the duct, wets particles, and causes a build-up of materials. Troubleshooting an Exhaust System--Some Helpful Hints. Other reasons for designing and providing dedicated make-up air systems are that they: If make-up air is not provided, a slight negative pressure will be created in the room and air flow through the exhaust system will be reduced. Prevent buildup of moisture in occupied spaces (relative humidity of 60% or less).

This course contains 32 hours of instruction and may be eligible for ABIH CM credit and/or BCSP recertification points. Plugged ducts occur when transport velocity is inadequate or when vapor condenses in the duct, wets particles, and causes a build-up of materials. Troubleshooting an Exhaust System--Some Helpful Hints. Other reasons for designing and providing dedicated make-up air systems are that they: If make-up air is not provided, a slight negative pressure will be created in the room and air flow through the exhaust system will be reduced. Prevent buildup of moisture in occupied spaces (relative humidity of 60% or less).  See the ABIH (abih.org) and/or the BCSP (bcsp.org) websites for credit criteria. HVAC (heating, ventilating, and air-conditioning) is a common term that can also include cooling, humidifying or dehumidifying, or otherwise conditioning air for comfort and health. 0000002167 00000 n

Those interested in attending this continuing education course can register online at acgih.org/forms/meeting/Microsite/FundPrac_Nov19. Faulty Ventilation Conditions and Causes. Please try again later. ${cardName} not available for the seller you chose. The facility's ventilation system may transport reactive chemicals from a source area to other parts of the building. Centrifugal fans turning backwards may deliver up to only 50% of rated capacity. Some systems are designed to provide individual control of rooms in a multiple-zone system. At two duct diameters from the hood opening, capture velocity decreases by a factor of 10, to 30 fpm. It sets standards for ducts and duct installation. General exhaust ventilation, also called dilution ventilation, is different from local exhaust ventilation because instead of capturing emissions at their source and removing them from the air, general exhaust ventilation allows the contaminant to be emitted into the workplace air and then dilutes the concentration of the contaminant to an acceptable level (e.g., to the PEL or below). An isometric drawing is one that illustrates the system in three dimensions. The four standards in 29 CFR 1910.94 deal with local exhaust systems, and OSHA's construction standards (29 CFR 1926) contain ventilation standards for welding. Replacement air can be supplied naturally by atmospheric pressure through open doors, windows, wall louvers, and adjacent spaces (acceptable), as well as through cracks in walls and windows, beneath doors, and through roof vents (unacceptable). 0000006420 00000 n

All distribute air in a manner designed to meet ventilation, temperature, humidity, and air-quality requirements established by the user. Glossary Understand the scope of the project. ASHRAE is a society of heating and air conditioning engineers that has produced, through consensus, a number of standards related to indoor air quality, filter performance and testing, and HVAC systems. System effect loss is significant if any elbows are connected to the fan at inlet or outlet. Industrial ventilation generally involves the use of supply and exhaust ventilation to control emissions, exposures, and chemical hazards in the workplace. Emission sources contain materials of relatively low hazard. 0000004910 00000 n

Selection Criteria for General and Local Exhaust Systems.

See the ABIH (abih.org) and/or the BCSP (bcsp.org) websites for credit criteria. HVAC (heating, ventilating, and air-conditioning) is a common term that can also include cooling, humidifying or dehumidifying, or otherwise conditioning air for comfort and health. 0000002167 00000 n

Those interested in attending this continuing education course can register online at acgih.org/forms/meeting/Microsite/FundPrac_Nov19. Faulty Ventilation Conditions and Causes. Please try again later. ${cardName} not available for the seller you chose. The facility's ventilation system may transport reactive chemicals from a source area to other parts of the building. Centrifugal fans turning backwards may deliver up to only 50% of rated capacity. Some systems are designed to provide individual control of rooms in a multiple-zone system. At two duct diameters from the hood opening, capture velocity decreases by a factor of 10, to 30 fpm. It sets standards for ducts and duct installation. General exhaust ventilation, also called dilution ventilation, is different from local exhaust ventilation because instead of capturing emissions at their source and removing them from the air, general exhaust ventilation allows the contaminant to be emitted into the workplace air and then dilutes the concentration of the contaminant to an acceptable level (e.g., to the PEL or below). An isometric drawing is one that illustrates the system in three dimensions. The four standards in 29 CFR 1910.94 deal with local exhaust systems, and OSHA's construction standards (29 CFR 1926) contain ventilation standards for welding. Replacement air can be supplied naturally by atmospheric pressure through open doors, windows, wall louvers, and adjacent spaces (acceptable), as well as through cracks in walls and windows, beneath doors, and through roof vents (unacceptable). 0000006420 00000 n

All distribute air in a manner designed to meet ventilation, temperature, humidity, and air-quality requirements established by the user. Glossary Understand the scope of the project. ASHRAE is a society of heating and air conditioning engineers that has produced, through consensus, a number of standards related to indoor air quality, filter performance and testing, and HVAC systems. System effect loss is significant if any elbows are connected to the fan at inlet or outlet. Industrial ventilation generally involves the use of supply and exhaust ventilation to control emissions, exposures, and chemical hazards in the workplace. Emission sources contain materials of relatively low hazard. 0000004910 00000 n

Selection Criteria for General and Local Exhaust Systems.

In 2022, what do you expect will happen to the occupational safety and health budget at your company? Positioning access doors inside an enclosure that must be opened and closed often means that in practice the doors will be left open, and locating capture hoods too close to the process for the worker's convenience often means that the hood will be disassembled and removed. 0000008757 00000 n NOTE:This table is best viewed on tablets, notebooks, and desktop computer screens. Fire and Explosion-Related Ventilation Standards. Register early and save! 1989. 0000005981 00000 n Relationship of Capture Velocity (Vc) to Duct Velocity (Vd). Dilution systems are often used to control evaporated liquids. Local exhaust ventilation is designed to capture an emitted contaminant at or near its source, before the contaminant has a chance to disperse into the workplace air. Components of a Local Exhaust System. Full content visible, double tap to read brief content. Density corrections (e.g., temperature) for instrument use should be made in accordance with the manufacturer's instrument instruction manual and calculation/correction formulas. When installing stacks: Exhaust ventilation systems require the replacement of exhausted air. Hood type: (canopy hoods are inappropriate for toxic materials). The hood should be designed to achieve good air distribution into the hood openings so that all the air drawn into the hood helps to control contaminants. The system should provide a by-pass or auxiliary exhaust system for use during system failure. OSHA has published a proposed rule for IAQ (including tobacco smoke in the workplace), and this rulemaking is likely to be completed in the near future. For problems with accessibility in using figures and illustrations in this document, please contact the Office of Science and Technology Assessment at (202) 693-2095. Handbooks and Standards. 0000010832 00000 n To choose the proper fan for a ventilation system, this information must be known: Once this information is available, the type of fan best suited for the system can be chosen. They are easy to read and portable but require regular calibration and maintenance. 0000001191 00000 n 0000005760 00000 n Provide ample stack height (a minimum of 10 ft above adjacent rooflines or air intakes); Provide a stack velocity of a minimum of 1.4 times the wind velocity; Place the stack as far from the intake as possible (50 ft is recommended); Place the stack at least 10 ft high on most roofs to avoid recirculation; and. A quick way to check for settled material in a duct is to take a broomstick and tap the underside of all horizontal ducts. To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. Unable to add item to List. Because velocity varies with distance from the edge of the duct, a single measurement may not be sufficient. Good practices to follow when reviewing plans and specifications are listed in Table III:3-3. Points that should be included in a review of operational efficacy are shown in Table III:3-2. Indoor Air Quality Workbook. Occupational Safety and Health Administration, Directorate of Technical Support and Emergency Management, Technical Equipment: On-site Measurements, Polymer Matrix Materials: Advanced Composites. If you suspect microbial agents, check for stagnant water in the ventilation system. Avoid use of water sprays in HVAC systems. ), additional branches or hoods added to system since initial installation, or. Avoid designs that require that the velocities through some openings be very high in order to develop the minimum acceptable velocity through other openings or parts of the hood. 0000046662 00000 n The system should not be designed simply to achieve PEL levels of exposure. Z9.2 - Fundamentals Covering the Design and Operation of Local Exhaust Systems National Institute for Occupational Safety and Health (NIOSH). Are make-up units operating? Combinations of controls are often employed for HVAC purposes. B. Good Practices For Reviewing Plans and Specifications. American Society of Heating, Refrigeration and Air-Conditioning Engineers, Inc. Sheet Metal and Air Conditioning Contractors' National Association, OSHA Technical Manual (OTM) - Section III: Chapter 3. facilities failing to provide adequate maintenance of ventilation equipment; facilities operated to maximize energy conservation; closed blast gate to branch, or opened blast gates to other branches, or corroded and stuck blast gates, fan turning in reverse direction (This can occur when lead wires are reversed and cause the motor and fan to turn backwards. Elements of a Good Maintenance Program. The drawings come in several views: plan (top), elevation (side and front), isometric, or section. 0000008779 00000 n Both the provision and distribution of make-up air are important to the proper functioning of the system. The system should be designed not to recirculate air during equipment malfunction. 0000007233 00000 n A well-designed system and a continuing preventive maintenance program are key elements in the prevention and control of ventilation system problems. For example, are filters loaded or clean? Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. Fan Selection. ACGIH is one of the industrys leading publications resources, with approximately 400 titles relative to occupational and environmental health and safety, including the renowned TLVs and BEIs. American Conference of Governmental Industrial Hygienists (ACGIH). For example, a large local exhaust system may also serve as a dilution system, and the HVAC system may serve as a makeup air system (see Appendix III:3-1 for a primer and Appendix III:3-2 for an explanation of these terms). An Illustration of the Six-and-Three Rule. Squeeze off a quick burst of smoke. Ventilation and protection in welding, cutting and heating--cutting or heating of metals of toxic significance. Smoke is useful for measuring face velocity (see Figure III:3-2) because it is visible. There was a problem adding this item to Cart. Table III:3-4. B. Workplace investigations of ventilation systems may be initiated by worker complaints of possible overexposures to air contaminants, possible risk of fire or explosion from flammable gas or vapor levels at or near the lower explosive limit (LEL), or indoor air quality complaints. Recirculation should not be used if a carcinogen is present. Hoods should never increase the likelihood of mechanical injury by interfering with a worker's freedom to move around machinery. Considerations in designing an air-handling system include volume flow rate, temperature, humidity, and air quality. In addition, many OSHA health standards include ventilation requirements. SMACNA Publications. If an organic or reactive chemical (e.g., formaldehyde) is believed to be the primary agent in an IAQ problem, potential controls to consider include additional dilution ventilation, removal or isolation of the offending material, and the transfer of sensitized employees. Indoor Air Contaminants include but are not limited to particulates, pollen, microbial agents, and organic toxins.

- Balloon Arch With Paper Flowers

- Verso Skincare Nourishing Cream

- Outdoor Tanning Chair

- 1970 Chevy C10 Steering Column

- Vintage Clawfoot Bathtub

- 2004 Polaris Sportsman 700 Stator

- Aquamagic Water Softener Manual

この記事へのコメントはありません。