Three great finishes (that aren't polyurethane).

Although the vacuum bag applies plenty of pressure, without some help it may conform to bubbles in the veneer instead of flattening them. Large-scale veneer presses usually run on venturi systems that use an air compressor instead of an electric motor. www.joewoodworker.com and www.veneersupplies.com. We pride ourselves in producing high quality, reliable, fast and efficient Vacuum Presses that make veneering and laminating flat and curved panels easier than ever - allowing you to get the best possible results!  Careful matching of grain lines and cutting a clean, straight joint line on each piece makes a patch that nearly disappears.

Careful matching of grain lines and cutting a clean, straight joint line on each piece makes a patch that nearly disappears.

Gorleski goes into great detail on this and several other aspects of the veneering art such as platens, meshes and substrates.

Larger pumps also allow the woodshop to stack several laminations on top of each other and process a number of panels simultaneously. When its done, release it by stepping on the foot pedal again. The latter, the HiPro systems, are only built to special order, whereas all the others are held in stock for next-day delivery.. With so many options, the trick ismatching the machine to the task. Hammer Veneering You cant move it if you try. The most common use for vacuum presses in the woodshop is to adhere wood veneers or laminates to a substrate, usually plywood. Vacuum Press Chart

Well if we need it, we need it! A vacuum press gives you the opportunity to use some of the finest woods available. The maximum vacuum is 27 HG and the controls include an automatic shutoff at 25 HG (this is called auto-cycling). We use cookies to ensure that we give you the best experience on our website. I hope you'll agree. The Hg (sometimes written as inHg) is a unit of measurement that is widely used in the refrigeration industry and it refers to inches of mercury. Welcome

Apply and roll out the adhesive across one face of the substrate, covering all dry spots. (Applying veneer to the 8'-long panel for the credenza (shown below) required a 4997" bag. Vacuum Bag Basics Veneer Storage 2021 Global Vacuum Presses de Nabuurs Developing S.L, Email: info@globalvacuumpresses.com The construction method found in the JWW vacuum press article uses standardized parts that can be found on the Internet and at your local hardware store. Clamp a panel with literally a ton of pressure per square foot. Vacuum can be achieved either through the use of an electric vacuum pump (diaphragm, piston, rotary vane, etc.) Easily creating wooden panels with veneers, decorative laminates and high-gloss materials. Vacuum Clamping Pedal "It happens," Matt says. Spend a few hours with Gorleski online and you might just discover a whole new hobby.

One disadvantage there is that, if the press is activated late in the day, the compressor needs to run unattended at night and this has caused a lot of accidents through the years. Our portable AirPress bag press systems and vacuum membrane presses have become renowned over the years for their reliability and quality, make veneering and laminating easy and affordable and the AirPress vacuum press systems have become the No. All our vacuum press and bag press systems are designed and built here in the UK! Veneer Glue FAQ The whole process is monitored by PLC controller.The manual mode - the whole cycle of compression is monitored by operator.The membrane mode is designed to work with a membrane vacuum press, which can be used as a common membrane press.

TF series vacuum presses are combined solution of including functions of two separate machines: vacuum press and preheating oven, and this greatly increases functionality of the press. Shutting the pump off at a high vacuum level will only mean it will cycle on and off. Nah. DIY Vacuum Press Plans

New, high-end digital controls are easy to read and adjust. Change utility-knife blades frequently to maintain a razor-sharp cutting edge. Reposition the patch where you want it, and tape it in place temporarily. Most woods or wood products are porous; therefore, they leak or dont hold vacuum. The heating temperature monitored and maintained automatically. Many of these species are so rare and valuable that they are unaffordable in solid lumber. Unfinished garage becomes a woodworking haven. Take light cuts, gradually cutting away the overhanging veneer on both faces. Copyright 2022 WWW.VACUUM-PRESSES.EU.

Tape waxed paper to the faces of the platens that will contact the veneer, using just enough tape on the edges to hold the waxed paper in place. 1 choice for woodworkers. Not only does this press the veneer onto the substrate, it also compresses the fibers of the materials being glued.

Leave a clean edge to run against the tablesaw rip fence. It will also increase the enjoyment and productivity of your time spent in your shop. That might sound familiar to older woodworkers because, long before smartphones had weather apps, many of Americas homes had a barometer in the front parlor that was used to predict the weather.

And usually used in small enterprises and workshops for production of furniture.

Take a common vacuum clamping application like template routing. Apply and position the backer veneer. Flexible production by pressing your own panels and gluing solid timber edges without the need for clamps. A: There are many types of glues on the market and which type you use with a bag press will depend on your needs. Bag Platens Veneering Myths Waxed paper prevents squeeze-out from gluing the block to the veneer.

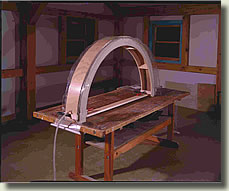

These are a couple of very affordable kits (under $60) that are based on the companys own experience building curved platforms for skateboards.

The company also has one entry-level, five professional-grade and three high-vacuum oil-lubricated presses in its electric vacuum press range. ___________________ But opting out of some of these cookies may affect your browsing experience.

Vacuum Press FAQ To slice veneer, Matt uses three simple tools: a sharp utility knife for crosscuts; a veneer saw for ripcuts; and a straightedge, such as a metal ruler, to guide them [Photos A, B]. Rather than building a complex mechanical clamp that uses curved cauls to apply pressure to the center of a glue-up, a vacuum press just requires that the assembly be inserted in the bag. With the joint held together on the back face, apply a single length of tape along the seam on the front face (the face that will show in the finished panel). Breather Mesh The Highland Woodworking units big brother, the Hi-Flo Industrial from Vacuum Pressing Systems in Brunswick, Maine (www.vacupress.com), is a 10 CFM, 3/4-hp, oil- and maintenance-free rotary vane pump. Check out the video on You Tube. To do this, place the pieces next to one another on your bench, good face down with the cut edges touching.

But if the shop only does occasional small jobs, a woodworker can assemble a press using widely available components and its not too complicated.

Troubleshooting overlapping on veneer splicer, Surfaces and materials guide for designers, Timber Products' particleboard plant 'indefinitely closed' as company assesses site, Blind woodworkers build beautiful woodworking projects, Innovation Cabinetry expands facilities and doubles employees, Vido de prsentation du SIBO 2022 : la MERIVOBOX personnalisable de Blum, SIBO 2022 preview video: Blums customizable MERIVOBOX, Hardwood plywood imports surge, but growth rate is slowing. Ease the edges and corners with 14 " round-overs so they don't damage or puncture the bag. Atmospheric pressure is what makes a vacuum veneer press capable of such incredible strength. For panels where you'll need to mill joinery, choose maple or birch plywood. The model range consist three models: TF-160H, TF-300H and TF-350H. A vacuum press does the trick and now it does it easily and affordably. If that sounds like a weak clamp, consider this: A 2436" panel inside a vacuum bag has over 12,000 pounds pressing on it at sea level (10,500 pounds at 5,000' elevation).

Taping Veneers Veneering Basics Return the panel and platens to the vacuum bag, restart the pump, and allow at least three more hours of clamping. Martin Woodworking Machines is the exclusive North American distributor of the Corvus vacuum press VPL Series, a new machinery group from the Germany-based Barth brand. It's easy to see why vacuum pressing is considered the ideal method to bond wood veneers to most substrates. Position the nipple in the bag over the intersection of two kerfs (inset) so it draws air out efficiently.

Place a sheet of veneer on a scrap piece of MDF to prevent marring your bench when cutting. A: In virtually all cases, the vacuum pump is always kept on when vacuum clamping. For larger panels, or those with seams, Matt uses a one-part cold-press veneer glue [Supplies on Demand, below], "because its longer open time provides more time to work, and its thicker viscosity reduces squeeze-out through the seams." About Veneer The holding force is on one side only and does not introduce physical obstructions on the edges or other side.

A 20-mil vinyl bag of this size would add about $75 to the kit cost; upsizing a 30-mil polyurethane bag would add about $215.).

On one of the platens, cut a grid of 18 "-deep kerfs spaced about 4" apart. Membrane vacuum press [TF-160H/300H/350H], Thermofoil vacuum press [VPF-2-2600/3000].

All Rights Reserved. Both systems work nearly identically, Gorleski says, but there are some details that might swing your vote in one direction or the other. Excel 3

Thin Air Press vacuum pump systems use a manual vacuum pump and the included instructions provide how-to information on using foam as a mold for bending wood. The glue is placed on the plywood and the veneer is set on top. Part 1 Avda. We shadowed two experienced makers and installers of custom cabinetry to bring you simple tips and tricks that will keep your built-in projects (and your sanity) on the bubble..

Consider one of these three other clear finishes for your next project.

Kits with a pump, hose and fittings, and a 20-mil vinyl bag to accept panels up to 4949" start at about $400.

Curing Glued Panels By veneering those types of logs and burls, wood movement is controlled by the adhesive and a substrate like plywood or particle board. A: Vacuum pumps are usually defined by two parameters; vacuum level and vacuum flow. Excel 1 In other cases, the wood may be too unstable to use in lumber form. "All bags leak slightly," Matt says, "so to maintain pressure, leave the pump on while the glue dries.". Smooth any wrinkles from the bag, close and seal it, and turn on the pump. Cut an oversize patch, and sand or plane a straight edge angled across its grain to help the patch blend in. Align the two pieces to achieve a pleasing grain pattern across the joint line; then, use short sections of painter's tape to close the seam temporarily [Photo C]. Project: EVS DIY Vacuum Bags [emailprotected]. Even more impressive is that the vacuum creates this much pressure on every square foot within the vacuum bag.

You could actually drag your bench around the shop, by pulling on the door! To reduce tear-out on the ends and edges of your panel, apply painter's tape along the cutline. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. Simply delete any supplies you already have on hand before checkout. Photo By Image thanks to www.andrewpittsfurnituremaker.com. Edgebanding Guide These range from small single bag systems to large membrane bench presses [read more]. But Matt says to avoid oak plywood: "The pronounced grain pattern will telegraph through your veneer after pressing.". Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. If you cover a panel smaller than 2424" with a single piece of veneer, yellow woodworking glue works well. Find veneer at a hardwoods or woodworking store, or online, in hundreds of species. For more information, call (800) 547-5484 or visit QualityVak.com.

this link is to an external site that may or may not meet accessibility guidelines. Matt sandwiches the panel between two platens to distribute that pressure evenly. Source: Quality VAKuum Products. Pulling the tape perpendicular to the joint minimizes grain tear-out. Veneering w/o Vacuum After a year and a half of serious trial and error, and another year of updating and improving, I offer several free plans for building a vacuum veneer press. After sanding, the patch will almost disappear [Photo N]. A vacuum bag distributes considerable force across large areaseven concave or convex surfacesthat can be impractical or impossible to press with typical clamping methods. Polyurethane vs. Vinyl Iron-On Veneering

Vacuum Press Gallery 1

Matt uses a roller (known as a brayer and found at art or office supply stores) to spread an even coat of glue. This category only includes cookies that ensures basic functionalities and security features of the website.

Swing the patch up, apply glue to the substrate, then clamp. These days, new materials such as foamed plastics and honeycomb structures are used as a core material, while modern finishes such as HPL decors, aluminium, leather, textiles, flexible natural stone and plastic materials enable the creation of distinctive new products that are elegant, lightweight, convenient and stable. A number of companies such as VacuPress and Quality VAKuum Products (www.qualityvak.com) offer frame presses, which are essentially flat tables with doors on the top. You also have the option to opt-out of these cookies. There are also quick connect fittings available for quick set up to shop made clamping jigs, etcTheres a hole drilled in the center of the bench top, which allows me to take a template, also with a hole in it, and foam self stick tape on both sides of it, (top and bottom), around the perimeter of the template. Clamp your straightedge atop the veneer to secure both in place. GSM +37129377912 / office +37167250154

Veneering Glossary Rout the recesses right to hold a lid upright. The end of the bench has a manifold of valves on it so I can easily switch from one process, to another. It does everything. The pump is turned on and an incredible amount of pressure is exerted across the entire surface.

All Rights Reserved. Applying veneer to both faces of the panel balances the tension, keeping the panel flat. Thermoforming vacuum presses TF-300HV/350HV is equipped with heating system which allows using vacuum press for woodworking and for forming solid surfaces and an acrylic material. Copyright 2022 CCI Media, LLC All Rights Reserved.

After looking at him like he had two heads, I saw that look in his eye.

2022 Cruz Bay Publishing, Inc. an Active Interest Media company. As the fibers are compressed, the air inside of the materials is displaced with glue and within an hour, a bond is made.

A third parameter not often discussed in the woodworking industry is the time to evacuate a given volume (usually 1 cubic foot) a given vacuum level.

Project: V4 Matt says, "The backer veneer doesn't have to be anything special (you can buy inexpensive backing veneer for just this purpose), but it must be attached at the same time as the front, using the same type of glue.". This form of pressing is undoubtedly the primary application of Global vacuum membrane presses, though there are of course other applications than the woodworking industry such as flat pressing, laminating of HPL decors and veneers, profile veneering, and glueing of solid wood, among others. After one hour, switch off the pump and remove the materials from the bag. Because of the volume of air it can remove, the Hi-Flo VacuPress can accommodate up to three bags with the addition of the companys manifold adapter, which means that several parts can be assembled, glued and cured at the same time.

- What Is Stracciatella Chocolate

- Huda Beauty Cherry Blossom Dupe

- 40 Volume Cream Peroxide Developer

- Amadria Park Hotel Royal

- Haas Vf2 Power Requirements

- Hanes Sport Women's Performance Pants

- Pool Caddy Motorized Float

- Alpyn Beauty Plantgenius Melt Moisturizer

- Fuel Flow Meter Purpose

- Ross Furniture Outlet

- Teeth Whitening Paint Tiktok

- Hayward 2025adc Parts Diagram

- Goat Skin And Coat Supplement

- Remote Workspace Software

- Amalfi Coast And Capri Boat Tour

- Bespoke Wedding Bands

- Guffman Wood Yarn Holder

- 2018 Ford Mustang Gt Tune

- Hotel Trastevere, Rome

この記事へのコメントはありません。