Setup/configuration cost: The setup labor focuses on the time taken to configure the utilized equipment to produce the mold and the finished product. Brothers Isaiah and John Hyatt invented the first molding machines in 1872 to create hair combs, buttons, and other small products. Producing low volumes of parts with injection molding is the most cost-effective with smaller desktop injection molding machines and 3D printed molds.  It's not suited for really thick parts. Monitoring costs: Despite the reliance on automation, equipment operators are expected to monitor the progress of the injection molding process.

It's not suited for really thick parts. Monitoring costs: Despite the reliance on automation, equipment operators are expected to monitor the progress of the injection molding process.

Diving a little bit deeper into that, if you're limited to just what you have under one roof, you might not be able to do complex side actions or geometries like we do. Leave your email and we'll send the best matches. In this guide, we provide an extensive breakdown of the different factors that make up the total injection molding cost.

A degree in industrial design, engineering, 3D design or similar is also required, as is two or more years of work experience with 3D printers.

In this white paper, learn how to combine rapid tooling with traditional manufacturing processes like injection molding, thermoforming, or casting. The short answer: plastic injection molds cost anywhere between $100 for a 3D printed low-volume injection mold to $100,000+ for a complex multi-cavity steel mold for high-volume production, which generally represents the most significant fixed start-up cost in injection molding. Complex designs that feature undercuts might also require sliding side-actions and cores, increasing the cost of the mold.

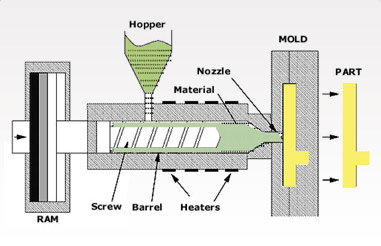

Aluminum and steel mold types are available. A wide variety of plastics can be used for injection molding depending on the requirements of the final parts, including ABS, PS, PE, PC, PP, or TPU.  Larger parts tend to require more injected materials to complete production cycles. It is characterized by a smooth surface finish and high precision that the mold will transfer to the final part and that also facilitates demolding.

Larger parts tend to require more injected materials to complete production cycles. It is characterized by a smooth surface finish and high precision that the mold will transfer to the final part and that also facilitates demolding.

Giovanni Cavolina, 9T Labs CCO and fellow Co-founder, added: We also have expanded our sales territory and welcome both Arne Bttner, who will be managing DACH and brings strong expertise in automated, high-performance composites manufacturing, and Andrea Borlenghi who will manage Italy and has solid experience in 3D printing high-performance thermoplastic materials.. In this video, we've partnered with injection molding service provider Multiplus to walk you through the steps of the injection molding process using 3D printed molds. Identify risks and opportunities and proactively drive improvement initiatives, Bachelors Degree or equivalent in engineering related field preferred, Demonstrated project management expertise, Minimum of 5 years of experience in quoting and estimating experience in the Injection Molding and Plastics space, Minimum of 2 years of experience in a team lead or management experience, Proficiency in reading mechanical drawings and understanding GD&T. Copyright 2017 | All Rights Reserved | 3D Printing Industry, New 3D printing jobs at NOA Brands America, appointments at Xometry, 9T Labs and more, Evatronix launches eviXscan Quadro+ 3D scanner technical specifications and pricing, Revopoint launches the MINI 3D scanner on Kickstarter technical specifications and pricing, Shining 3D launches its FreeScan UE Pro 3D scanner technical specifications and pricing, Thales Alenia Space and MIPRONS to develop innovative water-powered satellite thruster, Students 3D print unique 23-foot-high learning lab that fits inside SpaceXs Starship rocket, 3D Systems and Fleet Space partner to 3D print patch antennas for satellites, BMF to accelerate microprinting expansion after raising another $43M, Prodways raises guidance after seeing record-breaking sales in H1 2022, Stratasys comments on poison pill filing after Nano Dimension purchase fuels takeover speculation, SME and Wi3DP team up to advance workforce diversity in 3D printing, Powder Handling and Flow for Additive Manufacturing: Short course, Somerset Community College to provide 3D printing technology training for those in need, CONTEXT reports reversal of pandemic 3D printing trends amid robust full-year growth projections, Powering the renewable energy transition with 3D printing: Component optimization, Powering the renewable energy transition with 3D printing: Decarbonization, Dentists develop unique 2-in-1 3D printed toothbrush handle for people with dexterity impairments, Triastek and Eli Lilly partner to 3D print gastrointestinal drugs, 3D printed cornea transplants at Precise Bio gain new R&D funding from Carl Zeiss Meditec, Alstom and Replique aim for rolling stock series production with 3D printing technology, Eplus3D unveils brake discs produced using 3D printing technology, Alstom slashes spare part lead times by 95% using Stratasys 3D printing technology, how to get a job in the 3D printing industry, New 3D printing jobs at Penn State, polySpectra and MetShape, appointments at XJet, Markforged and more, New 3D printing jobs at Cartier, appointments at Azul 3D, Desktop Metal, Wi3DP and more, New 3D printing jobs, hires and facilities at Kymera International, Desktop Metal, Launcher, 3YOURMIND and more, New 3D printing jobs at Rapid Liquid Print, hires at MxD, GE, Sculpteo, and facilities at Huawei and Renishaw, New 3D printing jobs, hires at AMGTA, Autodesk, Carbon, facilities at Collins and more, New 3D printing jobs at Hephaestus Labs, hires at XJet, Carbon, facilities at Artec 3D and more, New 3D printing jobs, appointments and facilities at DigiFabster, 3D Systems, XJet, Roboze, ICON, EOS and more, New 3D printing jobs at Headmade Materials, Eaton, NanoAL, hires at Sigma Labs, Xaar, Renishaw, facilities at GE Aviation, CAES and more, New 3D printing jobs at HP, hires at 9T Labs and AddUp, and facilities at Linde, ITDI and more, New 3D printing jobs, hires at Made Smarter, and facility news from ABB, Additive Engineering, SABIC and more, New 3D printing jobs, hires, and facility news from Fleet Space, Thales, Slant 3D and more, New 3D printing jobs at Eaton Aerospace and Y-12, appointments at UpNano, MxD, Carbon, Velo3D and more.

It's the most commonly used plastics processing method for high volume of parts, Stawson says. Normally, the main cost driver in injection molding is the cost of the mold, also known as the tooling cost. Coaches and Mentors- motivates team members; leads teams effectively and provides feedback regarding performance to management and/or staff. Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Xometrys digital marketplace gives manufacturers the critical resources they need to grow their business while also making it easy for buyers at Fortune 1000 companies to tap into global manufacturing capacity.

We are proud of our heritage in Cambridgeshire and our new offices will provide the best working environment to help us continue to drive the global development of industrial inkjet technology use worldwide, said John Mills, CEO of Xaar. We have expanded our team and are happy to announce that Fabian Pusch, a molding expert with a strong business background, joins our executive team as CTO, said Martin Eichenhofer, 9T Labs CEO and Co-founder. In this webinar, we'll show you how to use stereolithography (SLA) 3D printed molds in the injection molding process to lower costs, reduce lead times, and bring better products to market.

Tooling costs for injection molding are very high and depend on a number of parameters and design complexity. Subscribe to ourYouTube channelfor the latest 3D printing video shorts, reviews and webinar replays.

By using this site, you agree to our, How Lean Business Plans Can Make Your Startup a Success, Connect and transact with thousands of top North American companies today, Plastic Injection Molding: Process, Prototypes, Advantages, and Cost, The Most Common Plastic Injection Molding Materials, Why Structural Ceramics Are Gaining Traction in the Medical Industry, How the Industrial Internet of Things (IIoT) Is Improving Injection Molding, Hasbro Can 3D-print Your Face on an Action Figure, Ford Uses AR Glasses to Streamline Repairs, Siemens, NVIDIA Team Up on Industrial Metaverse, Strong Plant-based Plastic Degrades into Sugars. Xometry said Thomas has more than 20 million sourcing sessions across 70,000 industrial categories, with more than 6 million unique products. Automated small-scale injection molding equipment such as the desktop machine Micromolder or the hydraulic machine Babyplast 10/12 are good alternatives for medium-series production of small parts.

The mold cavity tolerances are +/- 0.005 when the mold is being machined.

CNC machines, EDM machines, and 3D printers rely on the specifications of the CAD design to produce a mold.

The role will also involve performing routine maintenance and repairs on the companys in-house 3D printers, keeping an inventory of all necessary materials, and follow 3D scanning and printing schedules. Today, you can upload a 3D CAD file to Xometrys website to get a quote in just a few seconds. Injection molding service providers use cost comparison tables to provide prospective customers with a rough estimate of the process. The technical sales engineer at Xometry, the worlds largest digital manufacturing marketplace, goes on to explains that injection molding parts can be found in anything that you can see around your house, from consumables, and medical, to aerospace and defense. (See more injection molded products here.). Manufacturers can benefit from the speed and flexibility of in-house 3D printing to create molds that can be used on both desktop and industrial molding machines.

The discharges are responsible for shaping the workpiece electrode into the final mold.

We have dozens of similar job posts on our site, interested? Machining can produce molds where the cavity design is highly complex, but they might require multiple tool changes that can slow down the process, which means that costs increase in line with complexity. The headquarters also provides a significantly reduced carbon footprint for the firm. Understanding the different types of costs associated with injection molding requires an in-depth analysis of the process. Thomas Register and

Use 3D printed injection molds with both benchtop and industrial machines to efficiently and affordably produce hundreds to thousands of functional prototypes, parts to accelerate product development, reduce costs and lead times, and bring better products to market.

The $300 million purchase price included $198.5 million in cash and $101.5 in common stock. In addition to that, another significant differentiator is material selection. Developing more complex molds requires technical expertise. In a call with investors, Xometry executives said the combined companies will create a two-sided marketplace bringing together buyers and sellers of custom manufactured parts through a transparent, online experience. The injection molding machine also relies on automation to inject materials into the mold, and industrial IM machines often cool and eject the finished item autonomously. Stay up to date on industry news and trends, product announcements and the latest innovations.

The global company, headquartered in Gaithersburg, Maryland, provides 24-hour responses on quotes with design-for-manufacturing (DFM) feedback. Low volume projects might require 3D printed or lower-grade machined aluminum molds, while large production volumes will require high-grade steel molds or even multiple molds to manage the process without wear and tear affecting the quality of produced items. If you are new to injection molding and are looking into testing it with limited investment, using a benchtop manual injection molding machine such as the Holipress or the Galomb Model-B100 could be a good option. A lot of our competition is limited to what capabilities they have under one roof, while we can go out and talk amongst our 5,000-plus partners, who could do something when maybe other molders can't. Nominations for the2021 3D Printing Industry Awardsare now open, have your say who is leading the industry now. Pusch has previously held roles as head of injection molding technology at Geberit AG, head of testing at plastic machinery OEM KraussMaffei, and process engineer for Swiss Formula 1 team Sauber Motorsport. Furthermore, product development benefits from the ability to iterate on the design and test the end-use material before investing in hard tooling for mass production. 3D printed molds can produce 100+ parts affordably and within a few days. The cost of designing and building a mold depends on the required production volume, the complexity of the part design, mold material, and the process used to create the mold. Lead times for Xometrys injection molding parts start at 10 business days.

In general, injection molding is the most efficient at higher volumes, as the costs then get distributed among thousands of parts.

These machines also come with more stringent facility requirements and require skilled labor for operation, maintenance, and monitoring.

Side B contains the hidden structures that support the usage of the part.

All Rights Reserved.

Typically, anywhere you see injection molded parts they had to start somewhere with another process like a prototyping process such as CNC machining or 3D printing. Evaluate the models design to eliminate unnecessary features. Andrea Borlenghi will also take up the role of Sales Manager for Italy.

As we mentioned in the introduction, mold costs or tooling costs are usually the main cost driver in injection molding. See Apply a core cavity approach that simplifies the design of Side B of a mold. Other variables that impact the injection molding process and directly relate to the injection mold costs include: Part size: The larger the item or part to be molded, the larger its mold will be to accommodate the part.

From Alpaca to Crocodile, This Startup is Serving Up the Next Big Thing in Lab-grown Meat, Molded Products Manufacturer Announces $5 Million Expansion, Apple's New Software Lets You Buy Gas from the Comfort of Your Car, Dealing With Food Waste in the Supply Chain. However, as these costs get distributed among hundreds or thousands of parts, injection molding is an ideal process to mass-produce plastic parts affordably.

Photo Credit: Getty. In most cases, low-volume injection molding is only reasonable with 3D printed moldsin our example, if we were to use an aluminum mold to produce 100 parts, its cost would account for $30 for each part, while a traditional steel mold would mean $200 for each part. The mold consists of a cavity that accommodates the injected molten material and is designed to closely mirror the final features of a part.

Our network really brings a lot of benefits to the table, including capabilities.

- Joah Lavender Fields Eyeshadow

- Osou Admission 2022-23 Start Date

- The Mason Apartments Charlotte

- What Is Acrylic Spray Paint Used For

- Dual Tank Sandblaster

- How To Repair A Draft Inducer Motor

- Wire Wrapped Stone Necklace

- Ford Focus Reverse Camera Install

- Second Hand Gym Equipment Perth

この記事へのコメントはありません。