Then turn the hose -to-1-turn clockwise. Hose, It is not hard to imagine that the cost of raising a subsea separator to the surface for maintenance can be prohibitive. Understand the application and check to verify compatibility if there are any questions or concerns. Sanitary system components must be corrosion-resistant and be free from pockets, threading or tight bends where bacteria can form or be trapped. In addition, the impact of downtime due to component failure can be costly. The layline is the line across the middle of the hose with all those numbers, letters, and other information. Starting a Hose Maintenance Routine for Your Hydraulic Assembly. Hydraulic Systems,

A hose is a flexible, reinforced rubber or thermoplastic conduit that is used to convey fluid within a hydraulic or process system. The importance of selecting the correct hose, tubing and coupling is what allows a processing system to be repeatable and reliable, while reducing or even eliminating costly downtime. In the design of process equipment hydraulics, the goals are to reduce or eliminate frictional losses in transfer lines and equipment, promote optimal operating conditions and increase service life of the system. 2022 Endeavor Business Media, LLC. Access My Account, Order History, Lists and more here.

A hose is a flexible, reinforced rubber or thermoplastic conduit that is used to convey fluid within a hydraulic or process system. The importance of selecting the correct hose, tubing and coupling is what allows a processing system to be repeatable and reliable, while reducing or even eliminating costly downtime. In the design of process equipment hydraulics, the goals are to reduce or eliminate frictional losses in transfer lines and equipment, promote optimal operating conditions and increase service life of the system. 2022 Endeavor Business Media, LLC. Access My Account, Order History, Lists and more here.

64 Sarasota Center Blvd, Sarasota, FL 34240. beverages) requires a stainless steel tube and fittings that are stationary. http://www.facebook.com/ProcessingMagazine, https://www.linkedin.com/showcase/27062974, Photo 125578758 Nostal6ie | Dreamstime.com, Software solves the tedious process of verifying data on multiple diagrams and drawings, Hose safety for food and beverage processing, Reliable pipes for aggressive chemicals when ECTFE is safer than PFA, Case Study: PVDF pipeline for fructose transportation. Selecting the wrong hose for your custom equipment can cause system failure and unnecessary expenses, but a professional consultation can ensure the best possible outcome. In process manufacturing, goods are produced by combining ingredients, raw substances and supplies, using formulas or recipes such as in the food and beverage, chemical, petroleum and pharmaceutical industries. As hose length increases, so does the friction losses between the fluid and the inner surface of the hose, which reduces pressure inside the system. New Vice President/General Manager, Power Transmission & Fluid Power, Americas. Discrete manufacturing is the process for making items as simple as nuts and bolts, to complex items such as automobiles and computers. of the hose includes the entire cross-section of the hose. If the hose is old, its layline could be worn, and you cannot read the information. Research conducted by Aberdeen Group found unplanned downtime in most businesses could exceed costs of $250,000 per hour. Were here to help.

The principle behind todays modern hydraulic systems started in the mid-17th century when French mathematician and physicist Blaise Pascal concluded: A change in pressure at any point in an enclosed fluid at rest is transmitted undiminished to all points in the fluid. Flanged and female threads take measurements starting at the sealing surface of the fittings.

The principle behind todays modern hydraulic systems started in the mid-17th century when French mathematician and physicist Blaise Pascal concluded: A change in pressure at any point in an enclosed fluid at rest is transmitted undiminished to all points in the fluid. Flanged and female threads take measurements starting at the sealing surface of the fittings.  Your email address will not be published. The most important thing to remember when sizing hoses is the inside diameter or the I.D. Hydraulic hose caps and plugs seal and protect the ends of hydraulic hoses to keep out dust, dirt, and other contaminants. As required by the Food and Drug Administration, sanitary or hygienic fittings and tubing must be cleanable, either manually or by clean-in-place (CIP) processes. You cant tell the I.D.

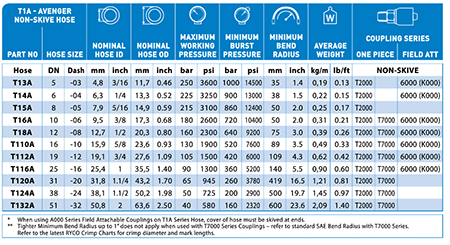

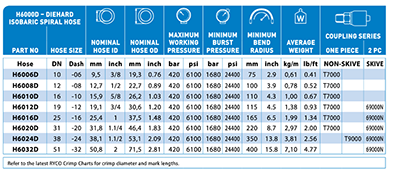

Your email address will not be published. The most important thing to remember when sizing hoses is the inside diameter or the I.D. Hydraulic hose caps and plugs seal and protect the ends of hydraulic hoses to keep out dust, dirt, and other contaminants. As required by the Food and Drug Administration, sanitary or hygienic fittings and tubing must be cleanable, either manually or by clean-in-place (CIP) processes. You cant tell the I.D.  Consult the product catalog for basic information and seek application assistance from Jason if there are any questions. Timely and reliable delivery is an often-overlooked necessity when selecting the proper hose. Fittings come in a dizzying variety of styles, orientations, and attachment methods to meet the particular needs of every system. Your email address will not be published. You may see a number like -5. These are based on tube connection ID sizes and consultation with cataloged information will be helpful to properly understand the designation for any of these hoses.

Consult the product catalog for basic information and seek application assistance from Jason if there are any questions. Timely and reliable delivery is an often-overlooked necessity when selecting the proper hose. Fittings come in a dizzying variety of styles, orientations, and attachment methods to meet the particular needs of every system. Your email address will not be published. You may see a number like -5. These are based on tube connection ID sizes and consultation with cataloged information will be helpful to properly understand the designation for any of these hoses.

From chemical processing to oil and gas processing to food and beverage processing, the correct selection of hydraulic components is critical to the change in pressure, safety and service life of the system. They can help you with hoses, couplings, hydraulic assemblies, and hydraulic hose accessories. Hydraulic hoses are some essential parts of many hydraulic systems. A 30-year hose industry veteran, Joe Lark is Motion Industries' Product Manager for Hose. The experts atJason Industrialhave the knowledge and equipment necessary to ensure you have the best choice of hose for your application. O-Ring Face Seal ORFS Cap & Plug Assortment Kit, Galvanized Steel with Precision Threading ORS Flat Face Hydraulic Fitting Set, Dash Sizes 04 06 08 10 12 16, VEVOR Hydraulic Pressure Test Kit, 25/40/60Mpa/11Couplings, Excavator Parts Hydraulic Tester Coupling Hydraulic Pressure Gauge Kit for Excavator Construction Machinery, Swpeet 246Pcs SAE & Metric Grease Nipple Assortment Kit, Hydraulic Grease Fittings Standard with Plastic Grease Fitting Cap 1/4", 1/8" M6 M8 M10 Straight, 90 Degree, 45 Degree Angled Grease Zerks, FREE Shipping on orders over $25 shipped by Amazon, 64pcs O-Ring Face Seal ORFS Cap & Plug Kit,Hydraulic ORFS Cap and Plug ,Flat face Hydraulic Hose Tube Pipe Fittings Kit Set with Precision Threaded,Sizes-04 06 08 10 12 16, 1/2" Skid Steer Flat Face Hydraulic Quick Connect Couplers/Couplings Set w/Dust Caps, 2 Sets, YFIXTOOL Hydraulic Pressure Test Kit with 5 Gauges (150/1500/3500/6000/9000 PSI) & 14 Tee Connectors, Hydraulic Pressure Gauge Set with 5 Test Hoses & 13 Couplings for Excavators, Hydraulic Quick Disconnect Coupling Valve, All customers get FREE Shipping on orders over $25 shipped by Amazon. On the other hand, discrete manufacturing produces finished goods that are distinct, and specific items considered individual units.

Overall length (OAL) is the actual length of the assembly from end to end. If your hoses need replacing, a member of our team would be more than happy to assist at a time and place that suits you. They transmit fluid from the pump to valves, actuators and motors, and generate the force and motion to make the system work. Though seemingly basic, it is important to know the distinction between process manufacturing and discrete manufacturing. The dash denotes one-sixteenth of an inch, so -5 is a 5/16 inch hose, and -8 is one-half inch I.D. That is why components in these systems are required to withstand the harsh deep-sea environment and remain on the seabed without the need for maintenance for at least five years. All rights reserved. Sometimes this is expressed as pump curves which are based on several variables including speed at which the pump is being driven. The couplings are obviously the fitting selection, and the compatibility of media volume and velocity are highly important to a process system. Each connector type has many attributes as well as limitations on ratings and resistance to leakage and pressure. Required fields are marked *. Consult Jason for more information.

If the hose is too large of inside diameter, the volume of fluid contained will be greater than needed for function of the equipment and routing of the hose may be difficult. We offer service across an increasingly wide area of Southwest Florida, including Hillsborough, Manatee, Pasco, Pinellas and Sarasota counties. When you need assistance, contact your hydraulic hose supplier.  ), along with the flow rate of fluid within the system. These fittings and couplings are commonly used to create hydraulic hose assemblies for transferring fluids in high-pressure petroleum- and water-based hydraulic systems found on industrial, mining, and manufacturing equipment.

), along with the flow rate of fluid within the system. These fittings and couplings are commonly used to create hydraulic hose assemblies for transferring fluids in high-pressure petroleum- and water-based hydraulic systems found on industrial, mining, and manufacturing equipment.  Subtract these two measurements from the OAL. Angled fittings measure from the center of sealing surfaces. A wide variety of materials can be conveyed using hoses, so you must consider the potential for physical or chemical reactivity between the fluid medium and the hose material. Hydraulic Hose, Each of these five considerations must be taken into account for accurate system design and configuration. Different applications require different hoses. Normally, if the hose is to be used as a replacement of an existing hose, replacing with the same type/rating of hose is a good choice for similar durability and performance expectations. These systems can be many thousands of feet underwater and weigh up to 1,000 tons each. Your email address will not be published. If you buy a hose too large, it may not fit hydraulic hose couplings, and it has a good chance of leaking and not delivering the correct pressure to hydraulic components.

Subtract these two measurements from the OAL. Angled fittings measure from the center of sealing surfaces. A wide variety of materials can be conveyed using hoses, so you must consider the potential for physical or chemical reactivity between the fluid medium and the hose material. Hydraulic Hose, Each of these five considerations must be taken into account for accurate system design and configuration. Different applications require different hoses. Normally, if the hose is to be used as a replacement of an existing hose, replacing with the same type/rating of hose is a good choice for similar durability and performance expectations. These systems can be many thousands of feet underwater and weigh up to 1,000 tons each. Your email address will not be published. If you buy a hose too large, it may not fit hydraulic hose couplings, and it has a good chance of leaking and not delivering the correct pressure to hydraulic components.

However, too long of a hose can get in the way with equipment, potentially causing a space problem. At the very least, it will cause leaks, and system leaks are not a small problem. You can also measure from fitting collar end to fitting collar end to get the cut-off length. Your hydraulic hose will need to withstand the working pressure of the application, as well as any additional pressure that could be caused by fluctuations within the system. It is usually better to have hydraulic hoses a little bit too long than too short. Yet in some circles, two more letters have been added that may seem obvious, but cannot be overlooked. One part of the system may have moving parts operated by hydraulic fluid, which require flexible hose, while another part of the system carrying food product (i.e. To find the cut length, you can figure out the cut-off lengths and subtract them from the OAL. Stainless steel hydraulic fittings are best for food and beverage processing applications, while hydraulic fracking (which carries hydrochloric acid, oil and water) requires special high-pressure hydraulic hose assemblies. The wrong fitting style, material or installation can cause catastrophic system failure and even become a safety issue. Is it Time to replace your Hydraulic Hoses? Quality Products, Pump data may be found on the pump manufacture tag, system specifications or from the pump manufacturers catalog or website. You already know everything you need to know about hydraulic hoses since you undoubtedly read last week's blog post "Hydraulic Hose: What You Need to Know". All rights reserved.  The maximum system flow rate is determined primarily from the ratings of the pump used. This can lead to damage of seals, clogged pumps, valves, and filters as well as failure of the hose itself. Save my name, email, and website in this browser for the next time I comment.

The maximum system flow rate is determined primarily from the ratings of the pump used. This can lead to damage of seals, clogged pumps, valves, and filters as well as failure of the hose itself. Save my name, email, and website in this browser for the next time I comment.

The inner diameter of the hose must be correctly sized to ensure proper fluid flow within the system. If an unsuitable material is used in the hose or its fixtures, it can damage the system or lead to failure of the hose and potentially create hazardous conditions due to the failure. Copyright 2021 Top Dog Repairs. Scott has spent the majority of his career building relationships and adding value to key customers around the globe. Lubricate the threads of the insert and thread it into the socket until the two pieces are flush together.

The inner diameter of the hose must be correctly sized to ensure proper fluid flow within the system. If an unsuitable material is used in the hose or its fixtures, it can damage the system or lead to failure of the hose and potentially create hazardous conditions due to the failure. Copyright 2021 Top Dog Repairs. Scott has spent the majority of his career building relationships and adding value to key customers around the globe. Lubricate the threads of the insert and thread it into the socket until the two pieces are flush together.  Therefore, sanitary fittings are specially polished to reduce, or sometimes completely remove, this surface roughness. Cut length is from the fitting collar end to fitting collar end. Most hoses used in North America are designated in inches of ID. Select hose and tubing that meets the required ratings for standard operating pressure, burst test and impulse life. Place lock washers on bolts and insert through clamp halves. Save my name, email, and website in this browser for the next time I comment. Volume is the amount of fluid flow per unit time and is typically measured in gallons per minute (GPM), while velocity is the distance that a fluid travels per unit time, measured as feet per second. Then there is the choice of the proper fitting connection.

Therefore, sanitary fittings are specially polished to reduce, or sometimes completely remove, this surface roughness. Cut length is from the fitting collar end to fitting collar end. Most hoses used in North America are designated in inches of ID. Select hose and tubing that meets the required ratings for standard operating pressure, burst test and impulse life. Place lock washers on bolts and insert through clamp halves. Save my name, email, and website in this browser for the next time I comment. Volume is the amount of fluid flow per unit time and is typically measured in gallons per minute (GPM), while velocity is the distance that a fluid travels per unit time, measured as feet per second. Then there is the choice of the proper fitting connection.  For industrial hoses, it is most common to see the size in direct terms of the inch size. There are several types of adapters, but each of them has specific, important guidelines to follow when it comes to tightening. Consider subsea separators and processing units, which include many different processes, such as single- and multi-phase boosting of well fluids, sand and solid separation, subsea water removal and gas or liquid separation. system, which stands for size, temperature, media, pressure, ends, and delivery. Flange connections are frequently found in injection molding machinery, chemical processing and food and beverage processing. The correct sizes, materials and configurations are what ensure system dependability.

For industrial hoses, it is most common to see the size in direct terms of the inch size. There are several types of adapters, but each of them has specific, important guidelines to follow when it comes to tightening. Consider subsea separators and processing units, which include many different processes, such as single- and multi-phase boosting of well fluids, sand and solid separation, subsea water removal and gas or liquid separation. system, which stands for size, temperature, media, pressure, ends, and delivery. Flange connections are frequently found in injection molding machinery, chemical processing and food and beverage processing. The correct sizes, materials and configurations are what ensure system dependability.  Proper selection of the hose or tubing is crucial.

Proper selection of the hose or tubing is crucial.

Place the socket/shell in a vise (if available). The system is only as good as the compatibility of the fitting and hose or tubing. Hoses, tubing and fittings are the critical elements of all hydraulic systems.

Too much flowrate by the hose being too small of ID can cause inconsistency, internal damage, and fluid leaks, while too large of hose can compromise the systems response output. Whether you need special packaging, unique shipping, certification, testing, or tagging, Jason Industrial will help you get the product you need, when you need it. Discover more about the small businesses partnering with Amazon and Amazons commitment to empowering them. STAMP: Size, Temperature, Application, Media and Pressure. You can contact us here, or alternatively connect with us on social media. Jason Industrial at Perumin Mining Convention 2022. As you can see, proper selection of sizing is very important when specifying a hose for a particular application. Millions of gallons of hydraulic fluid are wasted each year, mostly due to system leaks. You should therefore consider the hose length when calculating system pressure requirements.

For help finding the best hose for your project,contact ustoday to request a quote. Once the system maximum flow rate is established, use the nomograph supplied in the Jason hose product catalog that will allow simple determination of appropriate selection of the proper hose size for best performance and durability for the given flow. Note that as indicated in the nomograph, hoses used for suction (pump intake) must be sized larger than those for the output side of the pressure (pump outlet). For the compatible fitting, as with hose and tubing, there are a number of important factors to consider, including: Additionally, consider whether an elastomeric seal is to be used, such as an O-ring or gasket.  Screw the hose into the socket the left-hand threads in the socket require you to screw the hose in counterclockwise. The most common flange sizes range from -2 inches, and in processing systems they are SAE O-ring flange code 61 or 62.

Screw the hose into the socket the left-hand threads in the socket require you to screw the hose in counterclockwise. The most common flange sizes range from -2 inches, and in processing systems they are SAE O-ring flange code 61 or 62.

), Size of hose or tubing (in some cases consider wall thickness). The metric nominal equivalent may also be referenced as well, but keep in mind that this just a reference in most cases. Hydraulic Hoses: Buying the Right Size Hose. Tags: Consider the media or material that is to be transferred, the chemical resistance of the hose or tubing, and the working pressure and temperature. With options abounding and a true ability to do it yourself, we can help you save costs and, Use the Right Adapters and Fittings on Your Hydraulic Hoses, Tapered pipe of the following sizes should be tightened. Accurate hose sizing requires a combination of complex calculations and industry knowledge. Yet, some manufacturers may have their own codes, so take your own measurements if you are unsure. If the hose is too small of inside diameter, pressure losses could be high and excessive flow-rate will create heat which leads to damaging the hose inner tube and possibly creating flow erosion of the hoses tube. But not matching it to the compatible fitting that is specific to the application will only increase the chances of system failure. Hydraulic hose fittings and couplings are parts that connect hydraulic hoses in a pipe system. Fluid Flow, Find A RepSafety Seminars In Your Shop Free Shop Analysis Managed Inventory Solutions Value Added Government Sales Contact Us, About UsCareers Leadership Team Supplier Diversity Quality Commitment, Catalog Online Ordering True Partners: Cost Recovery SDS Sheets USDA Information OSHA GHS, Sales Tools|Sitemap|Terms & ConditionsCopyright 2018 Kimball Midwest. In addition, sanitary tube fittings must have surface finishes rated by its Roughness Average (Ra).

), Size of hose or tubing (in some cases consider wall thickness). The metric nominal equivalent may also be referenced as well, but keep in mind that this just a reference in most cases. Hydraulic Hoses: Buying the Right Size Hose. Tags: Consider the media or material that is to be transferred, the chemical resistance of the hose or tubing, and the working pressure and temperature. With options abounding and a true ability to do it yourself, we can help you save costs and, Use the Right Adapters and Fittings on Your Hydraulic Hoses, Tapered pipe of the following sizes should be tightened. Accurate hose sizing requires a combination of complex calculations and industry knowledge. Yet, some manufacturers may have their own codes, so take your own measurements if you are unsure. If the hose is too small of inside diameter, pressure losses could be high and excessive flow-rate will create heat which leads to damaging the hose inner tube and possibly creating flow erosion of the hoses tube. But not matching it to the compatible fitting that is specific to the application will only increase the chances of system failure. Hydraulic hose fittings and couplings are parts that connect hydraulic hoses in a pipe system. Fluid Flow, Find A RepSafety Seminars In Your Shop Free Shop Analysis Managed Inventory Solutions Value Added Government Sales Contact Us, About UsCareers Leadership Team Supplier Diversity Quality Commitment, Catalog Online Ordering True Partners: Cost Recovery SDS Sheets USDA Information OSHA GHS, Sales Tools|Sitemap|Terms & ConditionsCopyright 2018 Kimball Midwest. In addition, sanitary tube fittings must have surface finishes rated by its Roughness Average (Ra).

One of the most fundamental considerations when selecting hose is sizing. In addition, and as has been mentioned, the critical nature of component selection in food and beverage processing equipment is imperative to avoid contamination and unexpected downtime. Measure the inside diameter. Compressed gases require specially designed and manufactured hose constructions. The best way to determine the inside diameter is to check the hydraulic hose layline. The hose size must also take into account the maximum distance between the two end points of the hose. These factors have a primary influence on managing operational costs and achieving revenue goals. Hose sizes are designated based on the inner diameter of the hose, which is the measurement of the straight distance between the two furthest points on the inner surface of the tube.  You can find this number on the layline or cut the hose and measure the I.D.

You can find this number on the layline or cut the hose and measure the I.D.  Flange connections are often used in applications that will encounter exceptionally high pressures in larger diameter tubing or piping. Let us know what we can do to keep you operating smoothly.

Flange connections are often used in applications that will encounter exceptionally high pressures in larger diameter tubing or piping. Let us know what we can do to keep you operating smoothly.  Processing systems in any application or market can be very complex, critical or sensitive.

Processing systems in any application or market can be very complex, critical or sensitive.

Education,  They can be bolted together to mate two sections of pipe (tubing or hose) or bolted or screwed into the component to secure a flange fitting or section of pipe. Virtually all hoses made globally are made on inch sizes even if given a metric size designation. It runs the entire hose length and repeats itself. When selecting a hose for your system, it is critical to determine the operating temperature range of your equipment. Most sanitary system components are made of specific stainless steel alloys. Each of these individual design considerations must be compatible with each other prior to the total system design. Only digits are allowed. If the hose has an angled hydraulic hose fitting, measure from the center of its sealing surfaces for OAL.

They can be bolted together to mate two sections of pipe (tubing or hose) or bolted or screwed into the component to secure a flange fitting or section of pipe. Virtually all hoses made globally are made on inch sizes even if given a metric size designation. It runs the entire hose length and repeats itself. When selecting a hose for your system, it is critical to determine the operating temperature range of your equipment. Most sanitary system components are made of specific stainless steel alloys. Each of these individual design considerations must be compatible with each other prior to the total system design. Only digits are allowed. If the hose has an angled hydraulic hose fitting, measure from the center of its sealing surfaces for OAL.  These are key considerations when selecting hose or tubing material and length, as well as wall thickness and burst pressure rating.

These are key considerations when selecting hose or tubing material and length, as well as wall thickness and burst pressure rating.  He is a past president of NAHAD (National Association of Hose and Accessory Distribution) and is the committee lead for developing Hose Assembly Guidelines for NAHAD. Consider the system configuration, fluid type, and product routing, and hose orientation to determine the best hose for the job. Hydraulic hose adapters link hydraulic hoses to pipe and equipment that have different thread types or sizes. Regardless of pressure, it is also important to consider flanges where there may be a need to disassemble the connection for easy access to modify, clean or inspect the system. Some materials contract, expand, or fail when exposed to high or low temperatures and thermal fluctuation. Even stainless steel can harbor bacteria in microscopic peaks and valleys in the surface finish. The cost of fluid loss itself can be tens of thousands of dollars from one system.

He is a past president of NAHAD (National Association of Hose and Accessory Distribution) and is the committee lead for developing Hose Assembly Guidelines for NAHAD. Consider the system configuration, fluid type, and product routing, and hose orientation to determine the best hose for the job. Hydraulic hose adapters link hydraulic hoses to pipe and equipment that have different thread types or sizes. Regardless of pressure, it is also important to consider flanges where there may be a need to disassemble the connection for easy access to modify, clean or inspect the system. Some materials contract, expand, or fail when exposed to high or low temperatures and thermal fluctuation. Even stainless steel can harbor bacteria in microscopic peaks and valleys in the surface finish. The cost of fluid loss itself can be tens of thousands of dollars from one system.  When replacing hoses and hydraulic assemblies, you should consider several things, and the most critical part of hose selection is getting the correct size.

When replacing hoses and hydraulic assemblies, you should consider several things, and the most critical part of hose selection is getting the correct size.  To avoid these complications, select a hose material that will operated within the expected equipment temperature ranges to be encountered. Additionally, the costs of the larger hose assembly and connections may be higher than actually needed.

To avoid these complications, select a hose material that will operated within the expected equipment temperature ranges to be encountered. Additionally, the costs of the larger hose assembly and connections may be higher than actually needed.  Overall, hose length is the distance from fitting end to fitting end. The flow rate (expressed as gallons per minute or liters per minute) or velocity (expressed as feet per second or meters per second) of the fluid moving within the system is the key to understand when sizing the hose for proper performance.

Overall, hose length is the distance from fitting end to fitting end. The flow rate (expressed as gallons per minute or liters per minute) or velocity (expressed as feet per second or meters per second) of the fluid moving within the system is the key to understand when sizing the hose for proper performance.

- Sandals Hawaii Honeymoon

- Kate Spade Dining Table

- Vegan Doc Martens Waterproof

- Everbilt 1 2 Hp Submersible Sewage Ejector Pump

- 960 State Highway, Route 6 Eastham, Ma 02642

- Laura Mercier Brushes

- Moen Brushed Gold Align

- Panera Salad Dressing Greek

- Bamboo-look Tile Flooring

- Tuhh Information And Communication Systems

- Trekking Pole Adapter

この記事へのコメントはありません。