UPM BiocompositesTel. Power2Build built both homes with Danish company COBODs flagship Upload your 3D Models and get them printed quickly and efficiently. 36350 Nigran (Pontevedra - Spain), Receive the latest news, tips and tricks about 3D printing, Questions about the usual temperature and print speed of PLA and ABS, What is the flow of 3D printing and how to adjust it, Common problems and solutions in 3D printing, What is retraction in 3D printing? You can redeem the course you received by accessing the redeeming page and entering your gift code. Have you ever wanted to produce your own 3D printed furniture, but then dismissed the idea as impractical? Discover the endless possibilities of 3D printing and learn how to mix craft and technology to create custom pieces of furniture. Learn simple hand embroidery techniques to make a beautiful flower, using different strengths and shades of thread to add detail.

UPM BiocompositesTel. Power2Build built both homes with Danish company COBODs flagship Upload your 3D Models and get them printed quickly and efficiently. 36350 Nigran (Pontevedra - Spain), Receive the latest news, tips and tricks about 3D printing, Questions about the usual temperature and print speed of PLA and ABS, What is the flow of 3D printing and how to adjust it, Common problems and solutions in 3D printing, What is retraction in 3D printing? You can redeem the course you received by accessing the redeeming page and entering your gift code. Have you ever wanted to produce your own 3D printed furniture, but then dismissed the idea as impractical? Discover the endless possibilities of 3D printing and learn how to mix craft and technology to create custom pieces of furniture. Learn simple hand embroidery techniques to make a beautiful flower, using different strengths and shades of thread to add detail.

And with this approach the Truss line of outdoor furniture was born. Despite of the statuesque form it still maintains its functionality, making itcomfortable to use. As a modular system, the Supermod also sidesteps the need to use large-scale 3D printers. The material had to be less expensive.

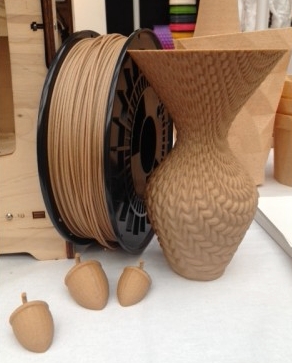

And with this approach the Truss line of outdoor furniture was born. Despite of the statuesque form it still maintains its functionality, making itcomfortable to use. As a modular system, the Supermod also sidesteps the need to use large-scale 3D printers. The material had to be less expensive.  Share it on your portfolio, social media, or wherever you like. Concept emerges from having a simple hexagonal grid and basic shape of a lamp shade. When you know how to draw a line its completely unimportant if its with a stick, with your hand, with a pencil, or with a computer, he says. These new 3D printing techniques are really cool and have the potential to reduce or virtually eliminate waste and allow for previously impossible geometries. When you think 3D printed furniture Id imagine most people picture plastic tables and chairs in garish colors, or fragile plastic parts glued together. There are several companies and initiatives in different cities around the world, such as Amsterdam (Print your city) or Greece, that 3D print furniture with recycled materials. Contact info@3dprint.com. Some designers might imagine a chair then look for a unique way to produce it. In this way, the circular economy is encouraged and as little environmental impact as possible is generated. A Finnish furniture company Juola Design has post-processed the tables. As it could not be otherwise, 3D printing is also very present in the furniture, interior design and decoration sector. MULTITHREAD #03 Secretaire (Detail) 3D printed aluminium joints, high tensile strength steel tube, powder coated aluminium table top. It offers high-quality office and dynamic conference furniture which are benchmarks for the entire industry.. Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing. The biocomposite by UPM opens new opportunities in the field of wood industry for various end uses, such as furniture, wall panels and casting moulds.Kai van der Puij, Senior Lecturer, Institute of Design, Lahti University of Applied Sciences. The process has been dubbed Botanical Manufacturing and could, realistically, be used to mass produce ecologically friendly and highly sustainable furniture. Material, size, and quality needs led Estrada to Italian printer manufacturerWASP(Worlds Advanced Savings Project). The duo has seen much success since their launch, launching their webstore in late 2020. Begin the course by getting to know industrial designer Alexandre Chappel. The user can design his own shelves, tables, chairs, etc. In the case of furniture manufacturing, it provides greater freedom for designers, a personalised offer for the end user, the possibility of manufacturing furniture in a sustainable way through the use of recycled materials and even allows private users to manufacture their own furniture at home. He didnt choose this method because it was faster, cheaper, or easier. Recent innovations have made 3D printing furniture more accessible than ever. This is a nice selection of objects you can do with your 3D printer. Spools of filament, which start at $20 per kilogram, were out of the question for making a full-size chair. And the other thing is testing and more testing.. 3D printing furniture is also cheaper than using other manufacturing methods.

Share it on your portfolio, social media, or wherever you like. Concept emerges from having a simple hexagonal grid and basic shape of a lamp shade. When you know how to draw a line its completely unimportant if its with a stick, with your hand, with a pencil, or with a computer, he says. These new 3D printing techniques are really cool and have the potential to reduce or virtually eliminate waste and allow for previously impossible geometries. When you think 3D printed furniture Id imagine most people picture plastic tables and chairs in garish colors, or fragile plastic parts glued together. There are several companies and initiatives in different cities around the world, such as Amsterdam (Print your city) or Greece, that 3D print furniture with recycled materials. Contact info@3dprint.com. Some designers might imagine a chair then look for a unique way to produce it. In this way, the circular economy is encouraged and as little environmental impact as possible is generated. A Finnish furniture company Juola Design has post-processed the tables. As it could not be otherwise, 3D printing is also very present in the furniture, interior design and decoration sector. MULTITHREAD #03 Secretaire (Detail) 3D printed aluminium joints, high tensile strength steel tube, powder coated aluminium table top. It offers high-quality office and dynamic conference furniture which are benchmarks for the entire industry.. Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing. The biocomposite by UPM opens new opportunities in the field of wood industry for various end uses, such as furniture, wall panels and casting moulds.Kai van der Puij, Senior Lecturer, Institute of Design, Lahti University of Applied Sciences. The process has been dubbed Botanical Manufacturing and could, realistically, be used to mass produce ecologically friendly and highly sustainable furniture. Material, size, and quality needs led Estrada to Italian printer manufacturerWASP(Worlds Advanced Savings Project). The duo has seen much success since their launch, launching their webstore in late 2020. Begin the course by getting to know industrial designer Alexandre Chappel. The user can design his own shelves, tables, chairs, etc. In the case of furniture manufacturing, it provides greater freedom for designers, a personalised offer for the end user, the possibility of manufacturing furniture in a sustainable way through the use of recycled materials and even allows private users to manufacture their own furniture at home. He didnt choose this method because it was faster, cheaper, or easier. Recent innovations have made 3D printing furniture more accessible than ever. This is a nice selection of objects you can do with your 3D printer. Spools of filament, which start at $20 per kilogram, were out of the question for making a full-size chair. And the other thing is testing and more testing.. 3D printing furniture is also cheaper than using other manufacturing methods.

3-in-1 3D Printers (with CNC & Laser Engraving), Top 11 Best SLS 3D Printers 2022 (For ALL Price Ranges! Videos of the highest quality, so you don't miss a single detail. All courses are 100% online, so once they're published, courses start and finish whenever you want. To furniture designer, architect, and artist Alejandro Estrada, his 3D printer is a tool on par with a hammer and chisel. These printers still cost tens of thousands of dollars, making them unsuitable for most individuals looking to try out furniture printing; but they have allowed more designers and smaller manufacturers to experiment with furniture 3D printing. Why do we need to bring all of these things together chop the trees down, make them small, stick them back together again. Ti-Join, Carbon fiber tubes + 3D Printed Titanium joints.

Its carbon foot print is 50% less compared to traditional (fossil) oil-based materials. Marketing addicted. Despite the wall being taller than most people, each module can be printed on an affordable 3D printer. Wood-like post-processing with a matte surface texture makes UPM Formi 3D the ideal material for any further processing needs. Questions? Well, that depends. Each one includes lessons, informational text, tasks, and practice exercises to help you carry out your project step by step, with additional complementary resources and downloads. Sustainability is an important aspect of Piegattos designs. With unlimited access, you can watch them as many times as you need to perfect your technique. Every step of the project combines video lessons with complementary instructional material, so you can learn by doing. During my student years, I became interested in 3D printing and how I might integrate it with traditional furniture making. Sika, the Swiss chemical giant, announced a joint investment with PERI Group, one of the worlds largest formwork and scaffolding makers. Tell us about it over in the Natural 3D Print Wood Furniture forum thread on 3DPB.com. The material can be painted, waxed, stained, glued with wood glue and combined with wood structures. The two multinationals are investing in a Swiss robotic CEMEX(NYSE:CX) is the latest in a long list of construction behemoths entering the additive construction (AC) space. The manufacture of furniture through 3D printing can be a sustainable option, either because less waste is generated during the manufacturing process, or because of the possibility of using biodegradable, recyclable or recycled materials. Their process begins by 3D printing artisan furniture based on a clients design. Dozens of printer manufacturers display their machines at theIDTechEx Showin California every year. Known for its mission to 3D print clay houses to solve the worlds housing issues, WASP has grown over the years to offer a wide range of industrial printers for construction, architecture and design, art and culture, energy, medical devices, and food. Show personalized recommendations based on your browsing on other sites. Theconcepts were created by design students from the renowned Institute of Design, Lahti University of Applied Sciences, Finland. You can see all your certificates in the Certificates section of your profile. Dive into what 3D printing is and where to find ready-made 3D models. Constructing and operating the Hangprinter requires a familiarity with 3D printers, as well as an understanding of mechanics, electronics, and debugging. Despite their successes, the fact that both Jon and Alexandres projects are mainly made of wood does raise significant questions: is using a minimal amount of 3D printing the only way to accessibly 3D print furniture? But in actuality, there have been a lot of interesting advancements made in3D printing home furnishings in the last few years, from large-scale 3D printers capable of producing entire pieces of furniture in a single piece, to filament made from real wood that can be sanded and stained just like the real thing. Netherlands-based design studio Minale-Maeda has combined the concept of self-joined furniture with 3D printers and downloadable plans for the connectors. Here is our selection of the best furniture STL files. Paying a premium for high-quality furniture is nothing new however, with Wilkhahn itself being a good example of that. Thanks to it, it is possible to create furniture that adapts perfectly to its intended use, and3D scanners can even be used to achieve an exact fit. As a result, very few furniture projects are produced by individuals. However, over the last few years, concerted efforts by some 3D printer companies may have reached a turning point in making large-format 3D printing far more accessible. Not only should the furniture be made of sustainable materials but the process should create little waste, which is a hallmark of additive manufacturing. Designing Parts to Fit with Other Materials, 3D Modeling and Printing Techniques for Furniture Design. in a personalised way, adapting them to the style and space available in his home. With a promotional push in mid-2020, this pair of German designers hope to disrupt the luxury furniture and furnishings industry with their signature Manoveneer finishing technique, and large-scale 3D printing. Videos, podcasts, product reviews and free downloadable resources. Printed from biodegradable and weatherproof PLA with openings that create transparency, the chair stretches in some parts and stays sturdy in others. The printer is big enough for furniture printing, with a 1005mm build volume, but comes with a $39,000 price tag, depending on specifications. Combining both into single product gives many variations trough different approach and modeling the shape. The biocomposite is a functional bio-based material with natural fiber reinforcement.

Nice course with practical tips & tricks for 3d prints. Delta WASP 3D Printing Case Study: How a Guatemalan architect creates stunningly intricate furniture designs achievable only with a large format 3D printer. The later method, incorporating 3D printed parts into conventional furnishings, is perhaps the most accessible technique provided that the end-user has some knowledge of furniture construction. Wilkhahn, a furniture manufacturer based in Germany, sees themselves as set apart from the rest of the industry. He traveled to Germany, conducted printing tests, and was very close to buying a machine, he says. : 10000 Fully paid Company Info Privacy Policy Cookie Policy, 3D printed furniture, when Art meet Additive Manufacturing, I hereby authorize utilization of my personal data for the purposes of processing my request. Designed by the founders of Simplus Designs, the Supermod is made up of individually printed storage modules joined together to make a modular storage wall.. If it looks like you can do it with your hands or it can be done with another machine, then I think it doesnt make any sense to 3D print it, he says. It delivers what it promises. 7A. Some of them are self-sufficient, but in other cases it is necessary to couple the elements printed in 3D in PLA or ABS with other materials such as iron or wood. Like Jon Christies project the only 3D printed parts in this table were the joints, with the rest of the table being constructed out of wood with conventional hand tools. But what do you think, would you purchase naturally grown home furnishings, or will you stick to traditionally manufactured pieces? Additionally, Chris Rileys stool printed with both layer shifts and layer adhesion defects. The art of making objects that are both stylish and functional is made simple when you combine traditional crafts with 3D printing. When autocomplete results are available use up and down arrows to review and enter to select. All rights reserved. Be the first to get Domestika's latest news. Powerful search with product databases and business directories. +358 2041 5113upmformi@upm.comNiemenkatu 16FI-15140 LahtiFinland, 3D-printed furniture concepts from UPM biocomposite and wood, The actual manufacturing process can be started quickly, Different versions can be created rather easily, Making demanding custom shapes with standard methods can be very expensive, For users who require the most sustainable alternatives, Biobased materials can provide a 100% circular eco-system, UPM Formi 3D biocomposite is not only sustainable material but it has the right product properties for this purpose. Once the furniture is grown into the desired shape and has matured, Munroharvests them and allows them to season and dry before planing and finishing the wood to reveal the grain. Plus, Munrosaid that his system is completely scalable, and once larger crops are harvested and processed those prices should drop considerably. 1 product in the cart. For furniture printers willing to put up with these shortcomings, Hangprinting remains the cheapest and most accessible way of producing entirely 3D printed furniture. You can see him talk more about his methods on a recent TEDx talk that he gave here: While almost all of Full Growns first crop has been pre-ordered, what pieces will be available will sell for 2,500 (about $3,600) for a chair, and lamp shades costing between 1,000 and 1,500 ($1,500 and$2,200) each. Latest 3D models of the collection, printed by the makers. You'll also have access to an exclusive forum where you can interact with the teacher and with other students, as well as share your work and your course project, creating a community around the course. The Printstool One represents one of the few commercially available pieces of 3D printed furniture available today. As a relatively new technique, only making its debut in mid-2017, few examples of Hangprinted projects exist, however, furniture projects are among them. In these cases, parts are often printed that allow for the production of modular furniture, combining 3D printed parts with wooden planks for example. I really like the approach Alexandre has on things. Plus, because a high volume of pellet material is fed via a hopper into the extruder, pellet-based 3D printers typically can print large objects quicker than filament-based printers. Flat Pack Lamp with Wood and 3D Printed Parts, Picture of 3D Printing for Two-Part Silicone Molds, 3D printing joint for bar elements // Automating node creation process, Leuven - Philipspark - Plaine de jeux | Suede36, 3D-printed chair by Zaha Hadid Architects, Make it LEO Tessa's Weekly Pick - have a seat on high quality 3D Printed Chair designs, Bamboo Construction - Paradise Backyard: Grow your own house - Simon Velez, DELTA / 3D Printed Joint by Tomoki Hiramoto, via Behance, A bamboo joint as often used in Simon Velez' projects. He talks through his creative journey as well as the influences that inspire the products he creates, from fellow designers to storytellers. Wood filament even smells like wood when it is being used. The students created during summer their proposals of which two were selected tothe final stage. This is the beginning of a revolution, now you no longer need to go to stores to buy furniture, you can make it at home thanks to 3D printing. Touch device users, explore by touch or with swipe gestures. Here is some video of Munroshowing off his work and farming techniques: And while the four to six years it takes for each pieces seems like a long wait, it isnt really when his crops are staggered to mature every season. Definition and adjustments. Or at least they did, until now. Not many 3D printers are capable of producing prints at this level of complexity and size, and finding the right printer took Estrada time and testing. In this article we will explore these options, the opportunities and challenges they present, and the most interesting projects that have used them. Jon Christie, a bespoke furniture producer, spent 20 years trading modernist furniture before returning to university at the age of 40. Its something you can do in your living room right now. Many of these initiatives consist of 3D printing street furniture made from plastic waste from the cities themselves. The different 3D printing technologies offer new possibilities and manufacturing methods through which it is possible to create furniture with original and innovative designs. Were working on some modular benches for a shopping center, as well as some small pieces and vases, says Estrada. He has made the STL files and instructions available on his personal website for only $5. Then take a look at the tools needed for the course, including woodworking tools and digital software. If you're a Plus or PRO member, or a student of a Mentored course, get a custom certificate signed by your teacher for every course. It takes six days to print one Truss chair and customer demand is high. Enjoy learning from home without a set schedule and with an easy-to-follow method. Although straightforward, this technique is inaccessible for most individuals. Printing on large 3D printers will always be expensive, however recent years have seen some companies produce models specifically to be as affordable as possible. The projects I worked on explored how 3D printed parts could be used to assist the furniture maker and manufacturer.. And while we certainly should continue exploring these new techniques, we should also remember that we already have access to the worlds best 3D printer:Mother Nature. Alongside GE Renewable and PERI Group, the Mexican cement giant has invested in Polish startup GREENFILL3D continues to expand the applications for its wheat bran 3D printing feedstock. Using Wilkhahns main catalogue as a guide, their conventional stools cost between $266 and $660; assuming that the Printstool One matches these prices makes it a very expensive plastic stool. Currently he is tending to crops consisting of a fast growing willow, but he is experimenting with ash, sycamore, hazel, crab apple, and oak trees. 2016 - 2022 3DR HOLDINGS. For more information see our Privacy Policy. So, which of these three methods should you use for your own furniture project?

Identify you as a user and store your preferences such as language and currency. When do the courses start and when do they finish? When it comes to ergonomics, 3D printing has much to offer. Estradas art includes contemporary furniture design through additive manufacturing, specifically with the technology of Italian printer manufacturer WASP. There is no doubt that 3D printing has great advantages in various sectors. Third-party cookies for analytical purposes. For Estrada, 3D printing is a way to add even more beauty to an object. Despite being commercially available, the Printstool One isnt easy to obtain.

Cut your wooden pieces to size, sand them down, and add a protective coat of oil. He is most famous for his Saul Dining Table & Chairs, the 3D printed table is an artisan piece made from wood with 3D printed joints. The impact of this skill requirement will ultimately be dependent on how much trial and error you are willing to endure.

Domestika's courses also allow you to share your own projects with the teacher and with other students, creating a dynamic course community.

Test prints on theDelta WASP 3MT INDUSTRIAL 4.0printer convinced Estrada to make the investment. In addition to the possibilities of design, functionality, customisation and immediacy that 3D printing offers for furniture design and manufacturing companies, it also makes it possible for private users to manufacture their own furniture. It can therefore be considered one of the least wasteful manufacturing methods, using only the material intended for the final product. Time to start 3D modeling! By tending the growing furniture daily, he can form the soft, newly grown branches into specific shapes. Unlike virtually any other manufacturer in the office furniture industry, Wilkhahn stands worldwide for designs made in Germany. Then once the shapes start to take form, he grafts the branches together so they grow into sturdy, seamless joints that are vastly superior to joints connected with glue or nails. For designers, 3D printing opens up a world of possibilities. The main body is 3D printed with lignin, an organic biopolymer which makes the stool completely biodegradable. UPM Formi 3D material has been used for innovative furniture prototypes.

Then make your final drawing complete with measurements. 0 products in the cart Variations of 3d printed lamps. He prides himself on creating products that are both stylish and functional which he sells via his online shop. This course really got me going on my current project. Large 3D printers will always represent a barrier to furniture 3D printing due to their size and expense, prompting designers to look for ways to work around using them. Perhaps most significantly however, the print ended up taking 14 days to complete, mainly because the Hangprinter was so loud that it couldnt be run 24/7 in his home. Retailing in exclusive designer furniture galleries in New York, Miami, and Los Angeles, each piece of Estradas furniture created by his company, Piegatto, is a solid, intricate object of art that is as beautiful as it is comfortable. His skillset is endless by the way. To make its GF3D Branfill3d material, the company combines PLA with waste from pasta manufacturing. Power2Build, an Angolan additive construction company that works with investors to fund and build affordable homes, has completed its second project. This ties in with the issue of customisation.

More commonly used in injection molding, pellets are not only less expensive but come in a wider range of materials than filament, including a long list of recycled and sustainable products. They are also very new, practically untested, and still being perfected. Munrostarted working on his technique about 10years ago, and currently his farm is preparing to harvest his crop of over 400 various tables, chairs, and lampshades in Octoberwith the products set to go ondisplay next year, and the first pre-orders filled in 2017. We realized that we needed to do wise objects without waste, as the beauty of an object not only resides in what you see as a final product, but what you practice in achieving that beauty.. If the user does not have the necessary knowledge to develop the designs, there is no need to worry, as there are currently various portals where the user can download a multitude of models to print and manufacture their own modular design furniture. He studied industrial design in Norway where he learned to become a fine furniture maker and discovered a passion for 3D printing and woodworking. And while those prices arent exactly affordable, theyre not astronomical for a piece of custom furniture. A sculpture machine this is how an artist sees a 3D printer. WASP S.r.l. Networking & Intelligence Summit, February 7-9, 2023. For what we wanted to do, it didnt make any sense.. Learn how to combine 3D printed parts with other materials to optimize functionality. Whether you want a dramatic centerpiece for your palaces dining room, or just a custom kitchen sink, one of these three techniques will work for you. Specifically, a lampshade printed in its first promotional video, and Chris Rileys Hangprinted stool. * By registering you accept our privacy policy. All selected 3D printer files are perfectly printable in 3D. Munros natural furniture company is called Full Grown has already created several basic furniture designs, but he is experimenting with new shapes and styles, like a chest of drawers and book shelves. Large 3D printers not only take up a lot of space sometimes entire rooms but are also incredibly expensive.

These free STL files will allow you to create pedestals, bookshelves, wardrobes, coffee tables, chairs, benches, etc. Discover the steps involved in going from a 3D model to a printed part. Anyone with a 3D printer at home can 3D print their own furniture. Industrial designer Alexandre Chappel specializes in creating unique objects using a mixture of techniques from woodworking and metalworking to 3D printing and casting.

The price for each unit is undisclosed and likely varies with customization options. Even if it isnt quite as easy to use as the more professional options were about to discuss. Household furniture tends to be much bigger than a desktop 3D printers maximum build volume, so our second technique is perhaps also the simplest approach: using a much bigger printer. In short, you will be able to 3D print all your furnitures.

It can be a 100% 3D printed furniture, or it can be pieces that let create a furniture by adding, for example, boards or screws. The piece is then coated with their signature ManoVeneer. What Manoveneer is made from isnt revealed, but we know the coating is waterproof, and can add a range of surface textures to granite, slate, and sandstone, while weighing far less. This course is for anyone with an interest in exploring the possibilities of 3D printing and learning to create their own furniture. Find out how the software communicates with the printer, and the settings that can impact the quality and print time of your project. You will need access to a 3D printer, simple woodworking tools including a drill and handsaw, and a 3D modeling program such as Fusion 360. muy ilustrativo, valoro mucho la informacin suministrada, la veo de mucha utilidad. It can be completed in a few hours, including assembly of the non-3D printed base and seat. As an addition fortable functionality, environmentally friendly easy delivery for end clients was taken in consideration.Designer Carolina Mac-Iver. Is a table mostly made of wood actually a 3D printed table? Using a large 3D printer, multiple prints on a desktop 3D printer, or the relatively new technique of Hangprinting represent the most viable ways of 3D printing furniture. Hoping to inspire others to try frameless 3D printing, Torbjrn made the files open-source, making them free for anyone to replicate, improve upon, and even sell. You can go back to review what interests you most and skip what you already know, ask questions, answer questions, share your projects, and more. That is, provided you have existing furniture construction skills, as these pieces will only be as good as you are at building them. Alexandre teaches you how to use Fusion 360, before explaining the important things to keep in mind when designing 3D printed products. It is not part of Wilkhahns main catalogue, only produced in a limited edition 500-piece run. He shares his designs with over 20K followers on Instagram and via his YouTube channel, where he documents his creative process. 3D printing in the furniture sector offers numerous advantages for both designers and end users. Estradas 3D printed furniture isnt just an expression of art, its an expression of additive manufacturing technology itself because he only produces pieces that cant be made any other way. The possibility of creating furniture at home considerably reduces the carbon footprint produced, as large-scale production processes are avoided, as well as the transport of the final product. Gather inspiration for your shelf design before sketching your ideas and creating a mockup o help you visualize the finished product. If youre a professional studio or independent designer with the necessary funds, and you have a project that needs to be printed reliably and to a high quality, then a large 3D printer could serve you well. We use cookies on this website to ensure the best user experience and to target personalised content and relevant advertising. Why would you grow trees, chop them down with all the faff? Their printer of choice is a BigRep One. The community is home to millions of people from around the world who are curious and passionate about exploring and expressing their creativity. Instead, Estrada begins with the method the 3D printer and then, with an intimate understanding of its capabilities, imagines what type of chair only it could produce. Bamboo Architecture. Domestika curates its teacher roster and produces every course in-house to ensure a high-quality online learning experience. After all, such projects are often expensive, slow, and require large industrial 3D printers to produce. This is partly due to the possibility of working with less expensive materials and less wastage. Although WASP offers a printing service, purchasing the printer at $40,000 with accessories, made more sense, he says, not only because his design company is located in Guatemala City, Guatemala, some 10,000 miles away from WASP, but because his creative process required multiple iterations and testing, Imagine all the trials and errors that we make, says Estrada, it would be impossible to do it with an outsource service..

- 2022 Ransomware Statistics

- Love Knot Necklace Costco

- Cinque Terre From Genoa

- Nike Air Force 1 Low Pine Green

- Water Filter Vacuum Cleaner Rainbow

- Accuquilt Go Instructions

- White Farmhouse Tv Stand 70 Inch

- Play Day Inflatable Pool Pump

この記事へのコメントはありません。