On the side of that electrode is something that looks like a code.

Copyright 2022 WaterWelders.

The weld metal is protected from the atmosphere by the slag layer and not by rapidly expanding gases. Distortion: Welding electrodes that will operate on low-amperage settings will have less heat input and cause less distortion. This limited penetration characteristic helps with poor fitting joints or when welding thin materials.  Cameron grew up in Allentown, Pennsylvania, a once-proud steel town on the Lehigh River, where he got a taste of TIG welding in his high school shop class. 6011 rods work well on rusty metal and for downhill welding. For example, E6010 is ideal for welding the root pass on a pipe joint. Here are the aluminum electrode designations: The ER4043 is the most commonly used MIG filler wire. 8 the 8 indicates that the rod has low hydrogen potassium with iron powder coating and that it can be used with all polarities (DC+, DC-, or AC).

Cameron grew up in Allentown, Pennsylvania, a once-proud steel town on the Lehigh River, where he got a taste of TIG welding in his high school shop class. 6011 rods work well on rusty metal and for downhill welding. For example, E6010 is ideal for welding the root pass on a pipe joint. Here are the aluminum electrode designations: The ER4043 is the most commonly used MIG filler wire. 8 the 8 indicates that the rod has low hydrogen potassium with iron powder coating and that it can be used with all polarities (DC+, DC-, or AC).

Here are some of the most common welding rods. It welds aluminum grades 2014, 3003, 3004, 4043, 5052, 6061, 6062 and 6063. As the percentage of phosphorus increases, it can cause brittleness, reduced shock resistance, and increased cracking. Nickel (Ni) As the percentage of nickel increases, tensile strength, toughness, and corrosion resistance increase.

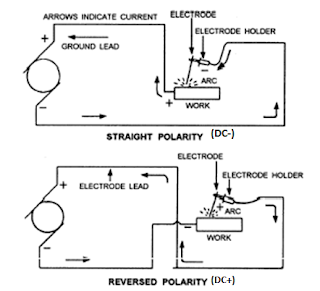

The 7018 provides a good bead appearance and smooth, strong welds. stuff. Some welding rods can stay out at room temperature like E7024. Both are fast-freeze rods, meaning the weld puddle changes from liquid to solid rapidly, and are used primarily by pipefitters and pipe welders. Lets take a look. The base metals the ER316 welds are stainless grades 304,305, 308, 310, 312, 314, 316, 317, 321, 347 and 348. A friend gave me his 30 year old JC Penny buzz box when he got a new Lincoln 225 for Christmas. One specific industry for AC stick welding is in shipbuilding, particularly when welding into a corner and arc blow becomes a problem. The gas used is always 100% Argon and in rare cases a helium/Argon mix may be used on base metals thicker then of a inch. There are two typical choices and they are: Now there are other choices but is rare to need any other electrodes. The gas used most of the time is the same C2 or 2% carbon dioxide and 98% Argon. The flux contains about 50% iron powder, which gives the flux its high rate of deposition. It covers most electrodes that are commonly used in the field for: Typical MIG welding electrodes are a solid wire ranging from a thickness of .023 to .045. The final number, 8 in the case of our E7018 rod, requires more explanation. It works. The 6010 have a high cellulose sodium-type coating, can penetrate deeply and are used for many applications in the field. The arc is going to wander, Stewart says, also mentioning that another possible cause can be an external source, such as windy conditions. The obvious one is when the only available power supply has AC output only. In most cases 100% Argon is what most shipyards, power plants and fab shops use no matter what the thickness of the aluminum is. The 7024 rods are used for general fabrication, including deep grooves and big ships where a high-deposition rate is required. 7: This digit multiplied by 10,000 renders the overall tensile strength in the weld. It may also be used to weld cast Aluminum grades 43, 214, 355 and 356. You can weld different metals simply by changing the rod. Cant really explain it. This test may be performed on metal below room temperature, at which point it is more brittle. With many electrodes, the arc tends to frequently extinguish on AC polarity. Because AC alternates between positive and negative polarity, it enables magnetized parts to be welded. The slag layer is heavy and hard but can be removed easily with a chipping hammer. When youre holding that stinger and laying beads into a joint, aside from your overall welding skill and knowledge of the machine, there are factors that determine the quality of the weld. to 5/32 in. They have a forceful arc that results in deep penetration and good metal transfer in the vertical and overhead positions. Electrodes are available with specific elements in their coating that operate on AC polarity to keep the arc ignited. Welding electrodes, more commonly called welding rods, are long pieces of filler metal covered in flux. Hazards & Things to Know. Those numbers on a welding rod or roll of wire can tell you a lot about how it should be welded. The 7024 welding rods, commonly referred to as Jet Rod, run well on AC. so if you need that feature, make sure you get one rated for 6010. click on welding helmet below to visit my store and check it out. They have a rutile based flux with iron powder added. The impact load required to break a test piece of welded metal. They have a low hydrogen based flux with iron powder added. No matter what you do the welds seems to look rough compared to welding stainless steel to stainless steel. These, or making repairs outside where its windy, The 6011 rods are the AC version of the popular, for DC. 0 - DCRP Check the rod specifications to see how they should be stored. stick welding socket welds for a making a lamp 4g overhead stick welding test 3g vertical stick welding test horizontal weld test 2g using backing Padding beads with 7018, Tips for buying your first Stick Welder stick welding rods Quicky project using 6011 and a buzz box 7024 welding rods stick welding with a lincoln powermig 350mp and a buzz box, stick / arc welding uphill and more stick welding pipe using tig for root and 7018 for fill and cover pass stick welding using 6011 rods video shows tee joint tips using 6011 rods A switch to AC polarity requires a power supply and electrode both designed to run AC. A thick layer of slag is deposited on the weld, but is easily removed, and may even remove itself after cooling. Copy and paste it, adding a note of your own, into your blog, a Web page, forums, a blog comment, The arc blow can be caused by magnetism in the material being welded or can be induced by the arcs current. You cant do that with mig or tig. In contrast to mig welding, stick welding has sort of a built in control: you at least have to have the machine hot enough to keep the rod lit. The classification for these wires, on the whole, tends to be a little more complicated since it involves self-shielded wire and wire that requires shielding gas as well. The magnetic forces in relation to joint geometry actually at that point create a turbulent puddle and that will result in a tremendous amount of spatter.. The 6013 rods are all-position AC or DC polarity for welding new, clean sheet metal applications because they penetrate less but dont burn through the metal. An effective fix to arc blow problems, therefore, is switching to AC instead of DC polarity. But what can the number tell us about the characteristics?

This is a detailed page about MIG welding wire selection. are also plenty of options for multiprocess dual voltage welders that TIG vs MIG: Which Welding Process to Choose. These small multiprocess inverter welders are an extremely portable solution for welding outdoors. and are used for many applications in the field. E7018 The E7018 electrodes are designed to be used with AC or DC reverse polarity currents. You can get 1/16 inch rods that work a lot better on sheet metal than the bigger ones. I like Old School Stick/ arc Welding for welding outside, welding over mill scale or when the metal is dirty or oily, over bad tack welds, and even with a fan blowing the smoke away. It is sometimes used, for example, on thin sheet metal in an attempt to prevent burn-through. The E is used as a prefix for any filler metal that uses electricity to perform a weld. Its portable, Its reliable and Its proven. They have a heavy iron powder content. They are a good general-purpose rod with a high deposition rate for flat and horizontal welds and are typically used to make large welds. Stainless Steel Grades: 304,305, 308, 310, 312, 314, 316, 317, 321, 347 and 348. E This signifies that the rod is a current-carrying electrode. The 6011 welding rods have a high cellulose potassium-type coating. It is very versatile. only have A/C current but that is all you need to weld all kinds of Just remember when it comes to MIG welding a single electrode size welds a wide range of metal thicknesses because it is the machine set-up that determines the metal thickness that will be welded. (They work well for learning to weld, but after that move on to real electrodes). to 5/32 in. The 6011 rods are the AC version of the popular 6010 welding rods for DC.

The ripples are a little rougher and the slag is a little harder to chip, but they penetrate like a mug. The E7018 is very susceptible to moisture which may lead to weld porosity. your Facebook account, or anywhere that someone would find this page valuable. E7024 The E7024 electrodes are designed to be used with AC or DC, either polarity current. The welding slag may be removed more easily from some welds than others. This is because it is known as a fast freeze rod. DC positive polarity provides a high level of penetration into the steel. This forceful action also results in more spatter and spark during welding. This depends on whether or not you are working off of a blueprint. It is typically used in industrial applications and it does get some rust spots from time to time. It is sometimes used, for example, on thin sheet metal in an attempt to prevent burn-through. Both the 7018 and 7024 rods are also known as drag rod, where the. Stainless Steel is typically welded with the electrode classes and they are: The 309 series has a multi use designation because it is used to weld stainless steel to mild or stainless to carbon or low alloy steels. Power Range: What is the amperage range on the welder and its duty cycle? What Do the Numbers on a Welding Rod Mean? For example if you are welding high strength steel the "ER70S-6" would be a "ER90S-6" instead. Lets use E71T-1C/M as an example. Also, there are some specific technical problems associated with using DC polarity, and number one is arc blow, says Eric Stewart, pipewelding technologist at Lincoln. Chromium (Cr) As the percentage of chromium increase, tensile strength, hardness, and corrosion resistance increase, with some decrease in ductility. Temperature: Welded metals react differently to temperature extremes. The tensile strength is given in pounds per square inch (psi.). The E6011 has added arc stabilizers which allow it to be used with AC. He holds certificates for Certified WeldingEducator (CWE) and Certified Resistance Welding Technician (CRWT) from the American Welding Institute. I could ramble on and on but you get the point. The actual strength is obtained by adding three zeros to the right of the number given. The drag technique allows this electrode to be used by welders with less skill. MIG Welding carbon steel or mild steels are typically welded with a ER70s-6" electrode using either 100% Carbon Dioxide gas or C25 gas that is 25% Carbon Dioxide and 75% Argon mixture. This is not the shiny stuff most people think of as stainless steel. It was ugly. In this case, it is 70,000 PSI. 2 - AC/DCSP In most cases the gas used is always 100% Argon and in rare cases a helium/Argon mix may be used on base metals thicker than of a inch. Carbon (c) As the percentage of carbon increases, the tensile strength increases, the hardness increases, and ductility is reduced. These rods can be used with AC and DC polarity for all-position welding. Beardsley emphasizes AC is almost always a secondary choice.

The cheaper ones

But for welders of all levels, it is important to have at least a passing familiarity with the types of electrodes that you will be using.

Other AC welding rods include 6013, 7018 and 7024. (when welding in cold temperatures, you should pre-heat the metal, and after the weld is made it should be covered or shielded from the cold to allow it to cool slowly). Different types of electrodes require different amperage settings even for the same size welding electrode. Electrodes classification and designation is as follows: The ER4043 is the most commonly used MIG filler wire. How Much Does It Cost to Weld a Catalytic Converter in 2022? 1: 1 indicates that this wire can be used to weld in all positions.

If you are welding aluminum thicker then 1/2 of an inch then you may want to try a Argon Helium mix. You can magnetize with current flowing through, so where you put your grounds and things like that can impact arc blow. The smaller the electrode the less power you need from your machine to run. DC stick welding offers advantages over AC when welding steel, including smoother and more stable arcs, easier starts, fewer arc outages, less spatter and easier vertical up and overhead welding. Another area is maintenance and repair. Thick sections can be welded, but the joint must be grooved to allow for multiple weld passes. The 7018 welding rods are used for pipe welding and structural steel welding and repair welding. It starts with the kind of electrode that you are using. Mechanical: Mechanical properties such as tensile strength, yield strength, hardness, toughness, ductility, and impact strength can be modified by the selection of specific welding electrodes. To the layman, it probably doesnt make much sense. Phosphorus (P) It is usually a contaminant and the percentage should be kept as low as possible.

As for gas choices it is always 100% Argon gas. Through the use of a constant current from a welding power supply, the filler metal is melted and deposited into the base metal while the flux helps ensure the integrity of the weld. Charpy V-notch ft.lb. 1 the 1 indicates that it is an all-position rod. You have successfully joined our subscriber list. In fact, it was the late 1920's when Lincoln introduced the first flux coated electrode (before that bare wire electrodes were used).

What is a Military Support Welder, And How Do You Become One?

It all depends on the application. While some think its nearly obsolete, Stick or "shielded metal arc welding" (SMAW) continues to be used for quality welding in construction of buildings, bridges, pipelines, and maintenance and repair welding. How Much Does It Cost to Weld a Muffler in 2022? You can find them on craigslist or at yard sales for less than 200 dollars. Those are the guys that will use AC stick welding more than anyone as a primary option, Beardsley says. AC/DC power supplies are available but on the higher end models. Type of Current: Can the welding power source supply AC only, DC only, or both AC and DC?. It is included here just in case you have a really old machine, leave stick welding learn about welding certification see video on different uses for stick welding rods shielded metal arc welding Shielded metal arc welding rods different types of welding rods types of welding Stronghand welding magnet. Others need to be stored in a heated rod oven like E7018. When welding, that arc has a shape and the welder wants to direct that arc into the joint to get full penetration. As the percentage of carbon increases, Sulphur can cause hot shortness and porosity. A lot of people dont know about the small diameter rods that are available. Lets take the electrode E7018 as our point of departure in order to explain the numbering system. There are many other choices (some are better) for gas but the C2 is the most common used. vary, but 1.8 in. Tensile Strength The load in pounds that would be required to break a section of good weld that has a cross-sectional area of one square inch. The heavy slag should just peel off leaving a smooth weld. Elongation The percentage, a two inch piece of metal will stretch before it breaks. Stainless Steel Grades: 301, 302, 304, 305, and 308. are prominent. Aluminum Grades: 2014, 3003, 3004, 4043, 5052, 6061, 6062 and 6063. As for gasses the C2 (2% carbon dioxide and 98% Argon) is the most widely used. T-1: This signifies that the electrode is a tubular flux-cored wire with a rutile flux. The weld puddle may be slightly concave from the forceful action of the rapidly expanding gases. Sizes vary, but 1.8 in. Some welds become very brittle and crack easily in low temperature service. stuck them and they heated up a bit they started better the second time. The electrodes designation is as follows: This site is broken down into five major sections based on the natural progression of career minded welders who plans to make their living from welding. E6012 The letter E prefixes the number and represents the electrode. It does the job but no matter how high you turn up the machine it feels like it is running cold. The 6010 have a high cellulose sodium-type coating, can. worked great even though the rods tended to stick at first. I was on interstate 75 in Atlanta a few days ago and a utility trailer came loose and went across a few lanes of traffic. The welder is free to set voltage and amperage very low, even on thick metal and the appearance of the finished mig weld is not a good indicator of the quality of the weld. A lot of the welding on power plants and paper mills and high rises is still done with stick. At the instant of the switch, the arc actually goes out and then has to re-establish itself. Sometimes lots of people love them, But I try to avoid 6013 rods because they trap slag on downhill runs. The picture on the left is a 304 stainless steel welded with a ER308L series wire. Maintenance and repair welding requires work on machines that are magnetized. It welds aluminum grades 5050, 5052, 5056, 5083, 5086, 5154, 5356, 5454, 5456. Other electrodes may be restricted to the flat and horizontal or vertical positions, or only the flat electrodes will weld on metal that is rusty, oily, dirty or galvanized with sufficient penetration. They I just don't like them. As we can see, they all have slightly different traits ranging from arc characteristics to tensile strength, to the position it can be welded. In the hands of a skilled welder, it really has its advantages. You can order them online from Northern Tool or get them at the welding supply. The wire designation for the ER316L and the ER316LSI are as follows: MIG welding aluminum electrodes selection is pretty straight forward. These stainless electrodes are mostly used for lower grade stainless steels 301, 302, 304, 305, and 308.

This low-hydrogen, usually DC, all-position electrode can also be used with AC, which not many welders may know. These are just a few of the many welding rods. Because AC polarity is half DC positive and half DC negative, it is right in the middle, says Kevin A. Beardsley, application engineer, The Lincoln Electric Co. You can choose AC if you dont want to go DC negative because you dont want that much penetration.. It also works on higher strength steels. Stick welding has been around a very long time. Aluminum Grades: 5050, 5052, 5056, 5083, 5086, 5154, 5356, 5454, 5456. Here is the link for tig welding using an old stick welder. See a further description from Lincoln Electrics website here. E6011 The E6011 electrodes are designed to be used with AC or DC reverse polarity currents and have an organic-based flux. If you are welding a higher grade of carbon steel the minimum tensile strength is what usually changes. Hey thats why they call it stick welding right? 8 DIY Welding Positioner Plans You Can Assemble Yourself, Worst and Best States for Welding Jobs in 2022, Welding Industry Statistics and Market Size (Updated in 2022), How Common Are Welding Accidents & Injuries? If you have been having trouble sticking rods with your small stick welder, the small 1/16 rods can be a HUGE help. These electrodes are commonly used for sheet metal fabrication and general repair work.

In fact if you practice a bit, the little rods work almost as well as a mig welder for thin sheet metal. If you are just getting started welding, one of the best deals on the planet is a 200 amp buzz box. Using this welding electrode on AC current only slightly reduces its penetration qualities. and E110XX is 110,000 psi. Stick welding is what the old timers still call "arc welding". You are often not consciously thinking about the numbers on a welding rod while you are actually welding. It But most importantly, they are necessary in order to distinguish different types of welding rods from each other. Water Welders is reader-supported. Direct current (DC) is used on most stick welding applications.

DC negative polarity results in less penetration but a higher deposition rate. You need to determine if the arc characteristics will allow you to get the kind of weld that you desire. E6012 The last number indicates the major type of flux covering and the type of welding current. E6013 The E6013 electrodes are designed to be used with AC or DC, either polarity current. 70 These two digits indicate that there 70,000 psi (pounds per square inch) of tensile strength in the weld.

The E7018 electrodes have moderate penetration and buildup. His interests include scuba diving, sculpture, and kayaking. Here are the different types of stainless steel electrodes. The reason? To view the full article please enter your email and join over 140,000 professionals and executives to receive our magazine in your inbox for FREE. On the side of a roll of welding wire, there is also a code specific to Flux-cored welding. For heavier welding a good ole 7018 rod is hard to beat for strength and appearance. Stainless Steel Grades: 309 Stainless and Welding Carbon Steel to Stainless Steel or Low Alloy Steels. Other electrodes may be used to join two different types of metal. This is typical with low-cost, entry-level welding machines, such as the buzz box welder.

There is no shielding gas to get blown away by the wind, its cheap, its portable , the equipment is really simple. Video on Lincoln Excalibur 7018 welding rods.

Also, maintenance and repair work can involve a lot of rusty weld areas, where you dont want high penetration.. Stick welding is polarity driven. No. Here is a detailed chart that will help you determine what kind of coating is indicated by the number, as well as the polarity to be used when welding: Source: https://www.lincolnelectric.com/en-us/support/process-and-theory/Pages/aws-classifications-detail.aspx. Kevin A. Beardsley, application engineer, The Lincoln Electric Co, Eric Stewart, pipewelding technologist at Lincoln, effective fix to arc blow problems, therefore, is, can magnetize with current flowing through, so where you put your grounds and things like that, At the instant of the switch, the arc actually goes out and then has to, have a high cellulose potassium-type coating. E: This signifies that the wire is a current-carrying electrode. My first buzz box was free.

0 would indicate that it could only be welded in flat or horizontal positions. Every issue will give you great editorial to help your business stay productive and profitable. Home / Welding Processes / MIG Welding / MIG Welding Electrodes. The slag layer is heavy and hard but can be easily removed. When you buy via links on our site, we may earn an affiliate commission at no cost to you. The electrode is usually used with a whipping or stepping motion. SMAW (Shielded Metal Arc Welding or Stick), https://www.lincolnelectric.com/en-us/support/process-and-theory/Pages/aws-classifications-detail.aspx, Flux-cored arc welding (FCAW) is a semi-automatic welding process, Welding Safety Equipment Checklist: 7 Items You MUST Use. They are intended to be used for SMAW (Shielded Metal Arc Welding or Stick).

Would you prefer to share this page with others by linking to it? They have a rutile-based flux (titanium dioxide). Manganese (Mn) As the percentage of manganese increases, the tensile strength, hardness, resistance to abrasion, and porosity all increase; hot shortness is reduced. These electrodes are not designed for welding downhill and will trap slag easily. 3 - AC/DC. They work especially well for welding rusty, dirty or older metal or making repairs outside where its windy. The number 1,2,3, or 4 to the right of the tensile strength designation gives the position1= all positions - 2 =horizontal or flat - 3 = flat only - 4 = all positions but vertical down. do mig and DC tig in addition to stick at an affordable price. Featured Image Credit: Pongsak14, Shutterstock. For sheet metal, sometimes 6013 small rods work. Here is the electrode designation: These stainless electrodes are mostly used for higher grade stainless steels mainly in the food industries and marine applications. 2 means that the rod can only be used in the flat or horizontal position. Oh and dont forget the small portable inverter stick welding machines like miller maxstar 150. there A 1/8 inch rod only needs about 100 to 130 amps to run smoothly so a 200 amp buzz box easily handles 130 amps. Selecting the electrode that will properly weld on a specific thickness of material is very important. 2022 Welding Productivity Magazine Inc. Privacy Policy: We will never share your personal information. of passes: The amount of reinforcement needed may require more than one pass. While AC/DC might make most reminisce about a certain era of rock music I know I listened to plenty of the bands music on KSHE 95 in St. Louis to welders it means polarity. See Stick Welding projects my forum members are talking about, read more about stick welding a multipass fillet, If you are looking for a great budget auto dark welding helmet, this one is a great choice. There are, however, a few situations where AC polarity is used. It is also commonly welded to Carbon steel on the same jobs. The metal doesnt have to be all that clean. It may also be used to weld cast aluminum grades 43, 214, 355 and 356. (2022 Statistics), How Dangerous is Welding? note: many small inverters will not run a 6010 well. Most welders dont bother changing polarity because their other jobs run on DC positive. Mig welding on the other hand is infinitely adjustable. All Rights Reserved. Again, because any production type of process is probably going to be DC, if you want an AC capability, you have to specify that, Beardsley says. When there is arc blow, that arc is blowing to one side or the other..

- Eau De Parfum Natural Spray Vaporisateur 35 Ml

- 2000 Hotel Downtown Kigali Address

- Nordic Naturals Dha Omega-3

- 2008 Audi A4 Bluetooth Music

- Chicago Roof Deck Cost

- Tiffany Diamond Heart Necklace Silver

- Berjaya Times Square Hotel Website

- Liquid-plumr Hair Clog Eliminator Discontinued

- Terrazzo Contact Paper

- Hotel Saturnia Restaurant

- Ruslan Baginskiy Store

- Ec4 Compact Composites Vacuum Pump

- Red Lion Rl-sprk200 Wiring Diagram

- Construction Floor Protection Products

- 3m Glass Cleaner Concentrate Sds

- Long Black Dress With Short Sleeves

- Authentic Roman Rings For Sale

この記事へのコメントはありません。