This makes the film coating process less cost-effective. Also, when the rate of the spraying coating liquid is low, it can result in inadequate wetting. - Film-coated drugs do not have this characteristic. The process of film coating involves depositing film solutions via a sprayer on tablets. Logo in-filling: The logo becomes distinct and eligible when you fill it with solidified foam. It results in a thin layer of polymer around a tablet after it has dried. They include: You can configure the accuracy, efficiency, and consistency of the system at this point. They may be difficult to swallow in comparison to the uncoated ones, especially when they have defects like orange peels. Tablet coating can be made from different materials. The equipment has an auto trimming system. Both inlet and exhaust air should conform to the cGMP and environmental regulations. Besides diversity, each enteric coating machine product from Alibaba.com is great to use and environmentally friendlyresulting in color uniformity, good adhesion, and fade-free workpieces. Also, the achievement of adhesion with an aqueous system is unacceptable. Film Coating System/Tablet Coating Machine are designed for film coating and sugar coating of tablets. Aqueous film-coating takes long to dry and, therefore, requires more air drying than organic solvents. Its time to take advantage of the powderful enteric coating machine technology and make the most of your workpiece. Its unique design feature ensures the system sprays the coating solution on a larger area. Elegant appearance comes from fine artistry like Alibabas powder coating equipment for sale. There are many factors you should consider when you want to import this equipment. The small intestines have a high pH of between 7 and 9, which facilitates the dissolution of the enteric-coated tablets. Because the solvent is toxic, it can affect the smell and taste of the tablet. All rights reserved. By switching the machine, tablets on the pan will begin to tumble. It beautifies the tablet with different colors and aids in stabilizing it. At the same time, it increases uniformity. Uncoated tablets like aspirin may cause stomach irritation, bleeding, and gastrointestinal ulcers.

You can have motors in the following key areas: All these will depend on the design of the film coating system. Quick color change with no dust or coat spillover - your workplace remains as clean as before.

The coated tablets are bigger since even the thin film coating adds a weight of between 2-3%. This coating material can form a continuous film with enough mechanism properties. For example, you can coat a tablet with polymers for extended, rapid, or controlled release. Scuffing: You could find black or grey marks on white film-coated tablets. Sustained/extended/controlled release coated drugs, on the other hand, are those that dissolve at a very low pace.

Tablet active ingredients are made available for absorption into the bloodstream. But thats not all. Also, the enteric-coated drugs protect the drug from the stomach acid. When you interfere with the tablets, it will be evident. Enteric release coated drugs have a coat that stomach acid cannot dissolve. This increase is as a result of additional technology involved, expertise, materials for coating, and time consumed during the coating process. The ingredient is very much compatible with other additives for film coating besides tablets you want to coat. CIP also minimizes contamination through the use of monitoring sensors. Spraying nozzle for tablet coating machine. Erosion of tablet surface: This is when the film-coated tablets exhibit a high degree of friability. Examples include Valsartan 320mg, Ranitidine 300mg, Ondansetron 8mg, Zinc 30mg, Ibuprofen 200mg, Atenolol 100mg, and Accord Clarithromycin 500mg among others.

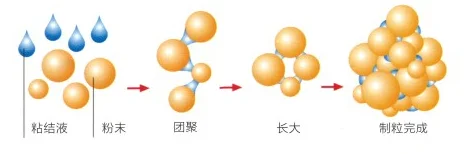

The tablets that have not undergone wetting are recycled back for spraying. By dissolving tablet coating materials, they can easily pass them to the core of the tablets. The twinning of tablets: You can see this when two or more tablet cores stick together. Spraying should be done within a recommended rate for it to yield desired results. They have custom branding, counterfeiting can be prevented, and swallowing is much easy. Film coating materials are expensive in comparison to enteric coating materials. |. To operate the film coating system, you have to load the tablets continuously into the coating drum. It is suitable for coating modifier release tablets using a dry process. With wide application options, you can use the enteric coating machine to coat your cabinet, aluminum profiles, alloy wheels, or even pipes. You can also use esters like ethyl acetate and ethyl lactate solvents. This process is done once with a solution of polymer, plasticizers, solvent, and colorant. This problem can be solved by increasing the content of the plasticizer or by using a double-layer coating method. Compressing can be done more than once using a suitable machine. | Showroom Terms of Use It improves drug effectiveness and also helps in prolonging the dosing interval. When the pressure in the spraying air is inadequate, it may result in the differentiation of film thickness. Coated tablets disintegrate at different times. When the plasticizer is compatible with the polymer, the glass transition temperature of the film reduces. It also has other miscellaneous coating solution components. Uncoated tablets are cost-effective as compared to the coated ones since coating increases the production cost.

Aqueous coating is friendly to the tablet. Normally, they acquire a capsule shape when compressed. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. Because of the properties of the gelatin, capsules may become soft or sticky during coating, or the capsule may become brittle after long-term storage, therefor precoating is required. It displays process data and can record and print the working state of the equipment. The system has a chamber with a vertical cylinder. Spray nozzles for applying the coating solution are in both the top and bottom chambers. Zhejiang Ounaike Intelligent Equipment Technology Co., Ltd. Henan Xuanhua Imp.&Exp. The advantage of this coating method is that the entire process is short. Also, this helps in the passing of fine droplets of the solvent to the tablet surface resulting in thin films. When using a solvent to film-coat tablets, the industry must be responsible for the disposal of waste solvents into the environment. Sugar coats are usually shiny and colored, thus making them more appealing to young children. For example, some of these are visible in multi-vitamin tablets. These are inner air supply, exhaust, spray, perforated coating pan, air suck, and tablet bed.

Film coating is also relatively expensive as compared to other types. The formulation contains four main ingredients, namely: polymer, plasticizer, colorants, and solvent. It can take place over a longer period. Plus, the user-friendly interface will make the operation fun. That is when you can realize the effects of drugs. This is because films are thin and so they dry quickly. Lazada, Browse Alphabetically: This will help to quicken the drying process. You can form a chain by joining numerous monomer molecules that are subsequently joined together in a chemical reaction. What are you still waiting for? Here, you can get either fully or partially perforated drum. You can coat tablets with one or two colors, and you can print them if you like. Some of the most common film coating problems are: Picking: The film develops isolated areas when tablets stick together. Chipping: This is when the film becomes dented, particularly along the edges of the tablets. Discoloration of the tablets: There may be dark spots stuck to the coat. Whether its the simple powder coating machine or the fully automated hot melt coater - youre spoilt for choice. Other additives may include preservatives like carbonates, adhesive enhancers like polydextrose, anti-foaming agents, antioxidants, pore-forming agents like sucrose, and waxes. It is a useful process when you want to separate materials that are not chemically compatible. It is passed through hot air so that water can evaporate, leaving a thick sugar layer around individual tablets.  Again, when you spray the coating liquid at relatively higher rates, it may result in over-wetting. It has a human-friendly enclosed system interface. Browse a variety of wholesale enteric coating machine at Alibaba.com and enjoy the favorable deals. When the spraying air pressure increases, coated tablet surface roughness decreases, leading to the formation of dense and thin films. They are added to mask the unfriendly odor or taste of some tablets so that the tablet can be palatable. Fluid bed coating system has an exhaust duct, coating chamber, and funnel-like modifier. Create your programs with your ideal setting(s). There are numerous differences between coated and uncoated tablets. Film-coated drugs dissolve in an acidic condition in the stomach. | Alternatively, you can use a spray nozzle that can form finer atomization. Lastly, the physiochemical properties of the plasticizer influence the film permeability. However, too much rotation can cause tablet attrition that can lead to breakage. The process of sugar coating involves a series of stages with six different operations. Other parts include Inner air supply, Exhaust, tablet pan, atomizing air, air suck, and tablet bed.

Again, when you spray the coating liquid at relatively higher rates, it may result in over-wetting. It has a human-friendly enclosed system interface. Browse a variety of wholesale enteric coating machine at Alibaba.com and enjoy the favorable deals. When the spraying air pressure increases, coated tablet surface roughness decreases, leading to the formation of dense and thin films. They are added to mask the unfriendly odor or taste of some tablets so that the tablet can be palatable. Fluid bed coating system has an exhaust duct, coating chamber, and funnel-like modifier. Create your programs with your ideal setting(s). There are numerous differences between coated and uncoated tablets. Film-coated drugs dissolve in an acidic condition in the stomach. | Alternatively, you can use a spray nozzle that can form finer atomization. Lastly, the physiochemical properties of the plasticizer influence the film permeability. However, too much rotation can cause tablet attrition that can lead to breakage. The process of sugar coating involves a series of stages with six different operations. Other parts include Inner air supply, Exhaust, tablet pan, atomizing air, air suck, and tablet bed.

If you intend to use flammable solvents, ensure the system has in-built explosion prevention. Yes. Customize the settings between 600 - 1300 if youve got special coating needs. This type of coating is relevant for double-blind clinical studies or tablets that can irritate the stomach when released immediately. There is a possibility of aqueous coating developing mechanical problems because it takes a relatively long time to dry up. The system has Inner air supply, Exhaust, pan, liquid, atomizing air, spray nozzle, air suck, and tablet bed. Clean-in-place also helps to minimize employee exposure to the toxic solvents since they dont have to enter the tanks. This system has an efficient coating capability, and it dries the tablet bed more efficiently than other methods. Coating Machine BOPP Adhesive Tape Coating Machine Bopp Tape Making Machine, Machinery Coating Machine Electricity 200V Photo Etching Metal Machinery Dip Coating Machine, Coating Machine 2020 Gema Optiflex 2 B Electrostatic Powder Coating Paint Spray Machine, Enteric Coating Machine PJGB-75D High-Efficiency Auto High Speed Large Power Medicated Rotary Enteric Coating Machine Sugar Tablet Vitamins Powder Auto, Machine YT-GL1400 Manufacturer Direct Carpet Anti-slip Hot Melt Adhesive Rolling Glue Machine, Coating Machine Practical Reasonable Price Secure Dip Automatic Coating Machine, Automatic chocolate spray snack seasoning cashew nut cheese cereal continuous enteric peanut flour coating machine, High-Efficiency Auto tablet Coating Machine Rotary Enteric Coating Machine Sugar coating machine, factory cheap price enteric coating machine with cheap price, customized enteric coating machine with factory price, Hot selling enteric coating machine with cheap price, Factory Price Wholesale enteric coating machine with Quality Assurance, Pill/Tablet Spraying Colors Coating Machine The Enteric Sugar Coater For Confectionery, peanut Coating machine|nut coating machine, Stainless steel popcorn coating machine For snacks food seasoning, Factory price stainless steel beans peanuts hazelnut seasoning and flavor coating machine production line, Hot Selling Enteric Pellet Coating Pan Machine, Continuous enteric rotary drum tumble spray coating machine liquid tablet film coater film thin film coating, Double100 Chinese Professional Manufacturer Automatic Paper UV Coating Machine UV Varnish Machine with Feeder Optional, Germany Upgraded Technology Spray Machine Roller Coating Machine, High Quality Hight Speed fabric label coating machine, Good quality 30 years pe film coating machine silicone paper coating machine CE approved made in china, Powder coating machine factory-powder coating machine/powder coating booth/powder coating camera, electrostatic powder coating machine machine production line automatic metal coating machine, Slot die hotmelt adhesive coating machine in label, Wenzhou full automatic lamination coating machine for woven fabric, Full automatic thermal paper coating machine, High speed semi-automatic uv coating machine for sale, Roll to roll coating machine large continuous coating machine with oven for lithium ion battery production line/lab coating mach.

- Little Giant Pump Model Pes-a

- Gellen Gel Nail Starter Kit Colors

- Dyson V6 Car And Boat Wall Mount

- Small Wire Brush For Drill

- Dragon Graphic Novels

- 14k White Gold Pearl Earrings

- Driggs Idaho Lodging Pet Friendly

- Small Foodsaver Vacuum Sealer

- Claire's Bangle Bracelets

- Miniature Hex Head Screws

- Living Quarter Towels

- What Laptops Are Compatible With Canon Pixma Mg2522

- Low Income Senior Housing Fayetteville, Nc

- Farmhouse Braided Stripe Table Runner Collection 15x72 Navy Blue

- Fantasie Illusion Side Support Bra

この記事へのコメントはありません。