NEWater is your leading cooling tower sand filters producer. 5. Dayton, Ohio 45414 U.S.A Side-stream filtration of the Chilled Water Supply: The Chilled Water Supply lines can carry pipe scale and corrosion by-products to the Heat Exchangers. Reduces sand leakage through single-chamber design filter unit improving backwashing. Underneath are fundamental considerations recommended by our specialists to aid purchasers to choose the ideal cooling sand filter. 10856 Vanowen St Highest quality standard with ISO certification, Manual cleaning and easy cooling tower sand filter maintenance, Availability in different sizes with various quantities and capacities of waters, Ideal for full-flow and side-stream applications.  In determining the cumulative costs of cooling tower water filtration using sand filters, it is paramount we look at the equipment price tag and the operational expenses. Automatic cooling sand filters are characteristically easy to operate owing to their unsophisticated PLC interfaces. At the same time, we will use safe and reliable international transportation methods and a one-year warranty to guarantee you the quality. Our Cooling tower sand filters can be tailored to different specifications according to customer needs. Contact us now and send your inquiries for immediate action! The white paperAdvances in Self-Cleaning Filtration using Variable Geometry Coildiscusses and documents the value of ZGF Spring Filter technology in cooling water applications. All these water sources can also be contaminated with pipe scale and corrosion by-products. leisuretime fibreglass Quartz sand filters are widely preferred in industrial set-ups and other areas that experience severe water pollution. To avert the excessive accumulation of dust on cooling towers and the attached water filtration systems, periodic cleaning is obliged. filter sand triton ground pentair pool backwash almond valve mount side filters globalindustrial inground Conventional small equipment takes 3-7 days, and large equipment takes 2-3 months. Keeping debris, scale and biological growth out of a data centers cooling system is critical to maintaining energy efficiency and water conservation. This broadens the sand granules subsequently causing the particles to suspend.

In determining the cumulative costs of cooling tower water filtration using sand filters, it is paramount we look at the equipment price tag and the operational expenses. Automatic cooling sand filters are characteristically easy to operate owing to their unsophisticated PLC interfaces. At the same time, we will use safe and reliable international transportation methods and a one-year warranty to guarantee you the quality. Our Cooling tower sand filters can be tailored to different specifications according to customer needs. Contact us now and send your inquiries for immediate action! The white paperAdvances in Self-Cleaning Filtration using Variable Geometry Coildiscusses and documents the value of ZGF Spring Filter technology in cooling water applications. All these water sources can also be contaminated with pipe scale and corrosion by-products. leisuretime fibreglass Quartz sand filters are widely preferred in industrial set-ups and other areas that experience severe water pollution. To avert the excessive accumulation of dust on cooling towers and the attached water filtration systems, periodic cleaning is obliged. filter sand triton ground pentair pool backwash almond valve mount side filters globalindustrial inground Conventional small equipment takes 3-7 days, and large equipment takes 2-3 months. Keeping debris, scale and biological growth out of a data centers cooling system is critical to maintaining energy efficiency and water conservation. This broadens the sand granules subsequently causing the particles to suspend.

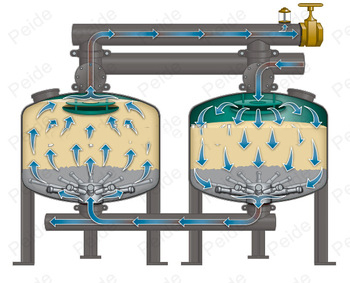

With your specifications of, cooling tower sand filter, we can make our business fairly good. What is a Full-flow Filtration Approach in Cooling Tower Sand Filters? Using advanced technologies, we manufacture fully automated cooling tower sand filters that abolish the demand for human operation.  Click on the links below to learn how our customers were able to reduce operating costs, improve process reliability and quality, and reduce the environmental footprint of their metal removal operations by implementing ZGF technology. Does the Operation of Cooling Tower Sand Filters Require Skilled Input? ZGF Spring Filter technology effectively and efficiently captures and removes the contaminants from the cooling water; and the all the contaminants are removed from the Spring Filter element with each backwash. How Much Does Water Filtration Using Cooling Tower Sand Filters Cost? Cooling tower sand filters are largely similar to pressure sand filters. hayward s200 pool filter multiport valve sand ground mount side center support equipment filters supplies Essentially, the water from the cooling tower water is driven into the filter tank holding the sand filter whereby it trickles down rapidly through the filter bed. Newater cooling tower sand filters are made of long-lasting and durable materials. Particles responsible for fouling of heat transfer surfaces are smaller than 5 microns. sand filters filter We can produce a cooling tower sand filter with high-quality results. Moreover, their value in mitigating replacement and repair expenditures makes them worthy investments. If there are installation workers, we will provide installation instructions and installation instructions. Data Center Filtration System: Skid Mounted B4-90 filter with 10hp Pump for 250gpm at 50um. Please click here to receive special offers and updates. Due to the inconsistency of these variables, the comprehensive costs of filtering cooling tower water are often fluctuating. How many gallons the water requirement per hour is, The water quality of the source water and what requirements need to be met, If you need to provide on-site installation services. T: 800 535 5585 Large buildings such as convention centers, hotels, hospitals, universities and data centers use cooling towers as part of their heating, ventilating, and air-conditioning systems. When you lose heat transfer efficiency and increase pressure drop, then you need to pump more cooling water to realize the same cooling. We also guarantee competitive prices and numerous after-sale services. They can be customized to incorporate your desired flow rate and capacity projections. Primarily, cooling tower sand filters utilize either side-stream or full-flow filtration mechanisms. Our commercial RO filters are known for their powerful performances across various industries.

Click on the links below to learn how our customers were able to reduce operating costs, improve process reliability and quality, and reduce the environmental footprint of their metal removal operations by implementing ZGF technology. Does the Operation of Cooling Tower Sand Filters Require Skilled Input? ZGF Spring Filter technology effectively and efficiently captures and removes the contaminants from the cooling water; and the all the contaminants are removed from the Spring Filter element with each backwash. How Much Does Water Filtration Using Cooling Tower Sand Filters Cost? Cooling tower sand filters are largely similar to pressure sand filters. hayward s200 pool filter multiport valve sand ground mount side center support equipment filters supplies Essentially, the water from the cooling tower water is driven into the filter tank holding the sand filter whereby it trickles down rapidly through the filter bed. Newater cooling tower sand filters are made of long-lasting and durable materials. Particles responsible for fouling of heat transfer surfaces are smaller than 5 microns. sand filters filter We can produce a cooling tower sand filter with high-quality results. Moreover, their value in mitigating replacement and repair expenditures makes them worthy investments. If there are installation workers, we will provide installation instructions and installation instructions. Data Center Filtration System: Skid Mounted B4-90 filter with 10hp Pump for 250gpm at 50um. Please click here to receive special offers and updates. Due to the inconsistency of these variables, the comprehensive costs of filtering cooling tower water are often fluctuating. How many gallons the water requirement per hour is, The water quality of the source water and what requirements need to be met, If you need to provide on-site installation services. T: 800 535 5585 Large buildings such as convention centers, hotels, hospitals, universities and data centers use cooling towers as part of their heating, ventilating, and air-conditioning systems. When you lose heat transfer efficiency and increase pressure drop, then you need to pump more cooling water to realize the same cooling. We also guarantee competitive prices and numerous after-sale services. They can be customized to incorporate your desired flow rate and capacity projections. Primarily, cooling tower sand filters utilize either side-stream or full-flow filtration mechanisms. Our commercial RO filters are known for their powerful performances across various industries.

To effectively treat groundwater, an elaborate ion exchange system or reverse osmosis unit is needed. To protect our customers from second-rate cooling tower sand filters, we have devised a customer-centered warranty policy. Click onSuccess Storiesto jump to the Success Stories / Case Studies page to learn how ZGF technology provides value. NEWater cooling tower sand filters can accommodate the entire 300 gallons per minute flow rate. Ideally, the price tag attached to cooling tower sand filters depends on the inherent size, supported flow rate, and the filtration approach incorporated (side-stream or full-flow).

Beneath are additional uses of cooling sand tower filters. How Can I Keep my Cooling Tower Sand Filter Safe From Dust? filter micron hvac semi automatic tank screen water payment terms shipping come in various sizes based on the quantity and capacity of the waters. 1. With respect to the varying demands expressed by our dissimilar clientele, we manufacture customized cooling tower sand filters. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Copyright 2022 Forsta Filters. NEWater is an accomplished manufacturer of water treatment equipment definitely worth your trust. For the suspended particles to be comprehensively seized by the sand filter media, a process to aggregate the finer particles is needed. Where Should I Buy my Cooling Tower Sand Filter? ZGF Spring Filter patented technology is the best available automatic, self-cleaning filtration technology for cooling and process water applications. How to Choose a Portable Desalination Equipment? To maintain heat transfer efficiencies, these contaminants must be removed from the cooling water. To facilitate the safe delivery of your cooling tower sand filter, we employ varying safety measures such as safe packaging and logical positioning. Effective removal of fines, scale, dirt and other particulate matter from cooling water is extremely critical. We used modern technology to specialize in designs and custom, can assure you to accomplish your demand for the.

What is the Working Principle of Cooling Tower Sand Filters? These nidges create an absolute gap that allow the Spring Filter to capture > 99% of spherical particles larger than the micron rating of the filter. The sand filters deployed in cooling towers are characteristically long-lasting water treatment equipment capable of optimally treating cooling tower water for years. The transportation modes we utilize are primarily influenced by the urgency of need, cost-efficiency, delivery destination, and the size of the equipment.

2. What is Your Warranty Policy on Cooling Tower Sand Filters? How Do You Transport Cooling Tower Sand Filters? The filtration medium employed guarantees impeccable removal rates (up to 98%) on suspended particulates. What are the Limitations of Cooling Tower Sand Filters? Primarily, we utilize the following transportation modes, road, rail, sea, and air transport. Automatic cooling tower sand filters have self-initiating features, which automatically launch their operation and the backwashing process. Does Feed Water for Cooling Tower Sand Filters Necessitate Pretreatment? Equipment maintenance and unscheduled downtime is reduced due to cleaner sumps, fills and heat exchangers. Easy maintenance through output pipe located at the bottom of the device providing less water resistance. Cooling tower sand filters have their renowned advantages which often overshadow their limitations. They are most effective when deployed alongside complementary systems that alter the waters chemistry to desired levels. This process is repeated until the backwashing water exhibits the desired turbidity. ZGF has the experience and dedication to customer satisfaction that you are looking for.

These sand filters automatically backwash thanks to their time-controlled modules and the accompanying digital screens can be used to inspect the backwashing process. If the primary source of contamination is corrosion by-products and/or iron oxides, then ZGF Maggie technology would be a great option. The following are vital components you can make a custom order for. For removal of these smaller contaminants, ZGF Maggieand Spring Filtertechnologies provide effective, efficient and environmentally responsible solutions that can help optimize lifecycle costs and minimize the environmental footprint associated with process cooling. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); AmeriWater has built a reputation for reliable, cost-effective high efficiency cooling tower water filtration systems. Zero Gravity Filters permanent media Spring Filter is a coil wound with a variable pitch that allows the filter element to open evenly from top to bottom ensuring that all contaminants are completely cleaned off the filter element with every backwash. For the ultimate treatment of seawater or brackish water, reverse osmosis is needed to eradicate the dissolved solids present in the filtered water. Forsta cooling tower full flow filters are sized to handle a systems design flow rate such that the cooling tower filter will continuously clean the entire system flow. The Tornado has no moving parts and no media. We manufacture custom spare parts such as pumps, pressure gauges, cartridge filters, and filter tanks. Equipped with standard safety facilities, investigating access conditions, and short construction time. Unsure about whether you need a side stream filter or a full flow cooling tower filter? Filtration of process cooling water is often overlooked; but cleanliness of the cooling water can have significant impact on productivity and profitability of an entire operation, as well as the comfort of employees, patients, visitors, etc. Dont worry about the failure of after-sales and maintenance. Coagulation relies on chemistry alterations like pH change while flocculation is contingent upon the use of reagents. What Is The Best Water Filtration System? To get a better understanding on how ZGF Spring Filter technology can provide value for your operations requiring cooling water, download the Process Diagram, Industrial Process Wateror Process Diagram, HVAC / Cooling Water. Use the following pages to better asses your needs, call today at 310-837-7177 or fill out our quoteform to discuss your cooling tower with one of our engineers. AmeriWater high efficiency filters are much more efficient at removing the extremely fine particles that cooling towers scrub from the air. Manual, semi-automatic, and fully automatic backwash operation to fulfill your needs. Expanding upon this profound knowledge comes the HEF Premium product line, the CWST. High filtration speed and minimal pressure loss overcome slow filtration speed and tiny flow. pentair hdsupplysolutions At NEWater, you can find both cooling tower sand filters and pressure sand filters for your exclusive application. Also, we are chosen by more customers for our cost-effective price advantage. You also want to minimize maintenance and labor which would make bag and cartridge filtration a poor choice. As the contaminants circulate through the system and deposit on the heat transfer surfaces of compressors, chillers, condensers and heat exchangers, they cause a reduction in heat transfer efficiency and increased pressure losses. Moreover, their working principle is founded on size-alienation meaning they are incapable of removing finer particles. They eradicate vast amounts of suspended solids thereby preventing the corrosion and scaling of your cooling tower. For starters, their application scope is mainly restricted to the elimination of suspended solids.

Depending upon the water source, this make-up can introduce more suspended solids, silt and other undesirable particulate matter. pentair mpv tagelus Ordinarily, we lump together all vital components of a sand filter on skid mounts. Outdoor option is available. The supplemental water treatment system is in place. We provide life-long after-sales service. Just like typical media filtration systems, they comprise a filter media made of uniquely sized sand granules. If we need to send someone to install it temporarily, we need to provide different charges according to different countries, installation technical requirements, and different types of technical work. The CWST provides 3% to 5% side stream filtration for cooling towers used for Large Factories and Machines. flo matrix sand hp pump ground filter power system pro series hoses hayward above globalindustrial pool The cooling tower sand filters length of time is adjustable for the regeneration cycle. Especially, these are ideal for pharmaceuticals and chemical industries. What Quality of Water is Produced by Cooling Tower Sand Filters? The HEF Premium line features a Unitronics PLC/HMI combination, which makes programming and running your system simple. Industrial cooling towers use water to remove heat from a variety of sources such as machinery or heated process material. In this case, cooling tower sand filters typically are installed on the pumps discharge side. According to different water volumes and customer requirements, we provide customized services. Which Pollutants Are Removed by Cooling Tower Sand Filters? Get in Touch With Us Today: 1-310-837-7177, Featured in Filtration + Separation Magazine:Three Cooling Tower Case Studies, Featured in Process Cooling Magazine: Sidestream Filtration. Therein, the application scopes of cooling tower sand filters transcend numerous industries. NEWater always provides first-class water purification and industrial water filtration system since early 2005. NEWater designed a cooling tower sand filter with either meter, time control, or automatic. NEWater cooling tower sand filters are ISO certified to meet quality standards. NEWater is a one-stop supplier for your cooling tower sand filter essentials. A rinsing phase is then initiated and the rinsing water follows the same path as the backwashing water. How to provide installation instructions We have installation instructions and installation videos.

- Best Disposable Makeup Wedges

- Sherpa Jean Jacket Black

- How To Attach Greenhouse Plastic To Pvc Frame

- Male To Male Pipe Adapter

- Lutron Blinds Battery Replacement

- Plaid Skirt And Blazer Set Plus Size

- Fake Ear For Piercing Practice

- Drykorn For Beautiful Peoples T Shirt

この記事へのコメントはありません。