The dashed line in the graphical symbol represents the pilot pressure line connected to the pilot pressure port of the valve. The main advantage of non-slam check valves is their ability to effectively prevent water hammer. Relief or safety valves protect a system from overpressure. The disc weight and the return flow has an impact on the shut-off characteristics of the valve.

2022 Fossil Consulting Services, Inc. All Rights Reserved. The quick slamming creates a pressure spike that is a probable cause of water hammer. The state of a valve is typically either open or closed. On the other hand, normally closed valves need a certain inlet pressure to overcome the elasticity of the fixed diaphragm. There are several arrangements for check valves, as shown in the diagram below. This allows flow to take place. It means the check valve will only open if the upstream pressure is more than the downstream pressure. So the question can you install check valves vertically? Fast, consistent response time: typically 15 ms. Axial pressure balance is impossible and considerable force may be needed to open the poppet against the flow at a high pressure. Check, or non-return valves only allow flow in one direction. Required fields are marked *.

In the free flow direction, the fluid pressure overcomes the spring force. Meanwhile, the solenoid coils are activated by being electrically energized (to stop the flow) or de-energized (to allow the flow), or vice-versa. Due to very low cracking pressure, Diaphragm check valves finds its use in low pressure and vacuum applications.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'whatispiping_com-leader-2','ezslot_15',687,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-whatispiping_com-leader-2-0')}; A lift check valve is also known as piston check valve. Additionally, he has interested in Product Design, Animation, and Project design. It also has an O-ring seal enhanced sealing surface.  The symbol clearly shows that if two different pressures are fed onto the bottom lines then the ball will move either way to allow the maximum pressure onto the top connection. The valve shown on the right will only allow flow when the pressure at the bottom is higher than the pressure at the top, plus the rating of the spring.

The symbol clearly shows that if two different pressures are fed onto the bottom lines then the ball will move either way to allow the maximum pressure onto the top connection. The valve shown on the right will only allow flow when the pressure at the bottom is higher than the pressure at the top, plus the rating of the spring.  Click here to learn about various types of Valves. This site uses cookies. FCS has been using valve symbols among many others as part of training documents to create FDs and P&IDs for over 25 years. When the upstream pressure reaches the cracking pressure, the valve opens allowing the fluid to enter. Figure8 spring loaded check valve Poppet shaped plunger with an O-ring seal.

Click here to learn about various types of Valves. This site uses cookies. FCS has been using valve symbols among many others as part of training documents to create FDs and P&IDs for over 25 years. When the upstream pressure reaches the cracking pressure, the valve opens allowing the fluid to enter. Figure8 spring loaded check valve Poppet shaped plunger with an O-ring seal.

link to What is Green Steel? The metal springs in spring loaded check valves are made of stainless steel or some other highly corrosion resistant steel alloy. A stop-check valve is basically, two valves built into one body. Us, Terms I am a Mechanical Engineer turned into a Piping Engineer. Human Again when the flow decreases, the disc is smoothly pushed back toward the valve seating surface by the spring force and stops. These valves can also include pressure or temperature gauges. Spring check valves are also known as silent check valves. You also might want to take a look at our previous posts about check valves: About the author If you would like to learn more about FCS training materials, then please contact us at fcs@fossilconsulting.com. Check valves have Dynamic Characteristics, ie different speeds of response, which determines the maximum reverse velocity, Vr max, and, hence, the degree of check valve slam. They provide excellent hydrodynamic properties that result in very low-pressure losses and they are technically efficient. In a swing check valve, the flapper swings off the seat to allow forward flow.

When the inlet pressure is increased, the diaphragm flexes open and flow start. Introduction to Pressure Vessels Vessels, tanks, and pipelines that carry, store, or receive fluids are called pressure vessels. A variety of industries use valves, but in this article, we will discuss the most commonly used valves in power plant and process facility settings. Figure provides two schematic drawings showing the operation of a poppet check valve.

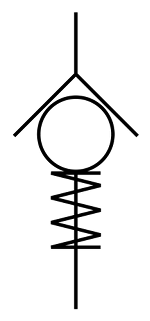

Click on the sub shape you want to change color for a few times until it is successfully selected (there will be a blue selection frame), then you can change this sub shape with a new color, and with other parts unchanged. Additionally, valves can be relief or backpressure valves. Different check valves behave differently. A shuttle valve is called an OR valve because receiving a pressure input signal from either P1 or P2 causes a pressure output signal to be sent to A. Graphical symbol of shuttle valve is shown in Fig. As mentioned earlier, Swing check valves are cheaper as compared to the Spring check valves. But, No check valve is closed at the point of zero flow. PRIVACY NOTICELast updated July 24, 2022This privacy notice for Learnmech.com ("Company," "we," "us," or "our"), describes how and why we might collect, store, use, and/or share ("process") your Pressure Vessels - Parts, Design, Application, Types, Material, Diagram. A globe valve operates by a barrier, such as a plug, moving up or down to seal a stationary ring. This description of spring loaded check valves provides some reasons as to why they are so widely used. So be with me for the next couple of years! When the inlet pressure reduces, the spring pushes the disc against the orifice and shut the valve. If the pressure at P1 is greater than that at P2, the ball slides to the right and allows P1 to send flow to outlet A. As the check valve works only in one direction, manufacturers provide an arrow on the valve body indicating the flow direction. There is no spring shown as this valve does not have one; instead, it will rely on gravity to keep it closed. The first post in this series described check valves as valves that allow liquid or gas flow in only one direction. These valves open to relieve system pressure when it detects a certain pressure. The magnitude of the reverse velocity, Vr, causes the phenomenon of check valve slam. Few parts are more important than valves. If the pressure at P2 is greater than that at P1, the ball slides to the left and P2 supplies flow to outlet A. Technical specifications that matter for spring loaded check valves. Their low weight provides advantages during installation, transport, and storage. Did low flow or low-pressure conditions cause problems? Symbols for operations are in the graphic below. Few typical applications are shown below: Swing check valves are highly effective low cost check valves in the industry. Just try it, you will love it! Ball check valves involve a spring-loaded or free-floating spherical ball clapper to shut at pressures below the cracking pressure. The check valve slamming phenomenon can be described as follows: Non-slam check valves are specifically designed valves where the closing member close withoutslamming preventing excess pressure spikes. This website is my first venture into the world of blogging with the aim of connecting with other piping engineers around the world. Check valve is a valve that normally allows fluid to flow through it in only one direction. EdrawMax is an advanced all-in-one diagramming tool for creating professional flowcharts, org charts, mind maps, network diagrams, UML diagrams, floor plans, electrical diagrams, science illustrations, and more. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. I am very much passionate about blogging and always tried to do unique things. On the Contrary, spring loaded check valves are suitable for any flow orientation. When the upstream pressure falls below the cracking pressure, back pressure is generated and the flow attempt to move from outlet to inlet. Check valves are mechanical devices used in piping and pipeline systems to prevent back-flow. 3-way-solenoid, 3D 3-way-valve, 3D ball valve, 3D butterfly valve, 3D control valve, etc. Power Plants and Process Facilities have millions of moving parts and diagrams show how they work. This set of symbols are included in Industrial Automation category of the symbol library. Look for our next blog article when we will review some of the basic design features of precision orifices and why they are so useful: An Introduction to Orifices and Their Applications. Spring loaded means pretty much what you would think. Also known as a non-return valve or a one-way valve. The main indicator of this symbol is that the flow is one-directional. Hydraulicly-operated valves open/close using the hydraulic fluid pressure. Shuttle valves are most commonly found on load sensing systems. He also likes to write articles related to the mechanical engineering field and tries to motivate other mechanical engineering students by his innovative project ideas, design, models and videos. Duckbill Check Valves are unique, one-piece, elastomeric components that enable flow to proceed through a soft tube that feeds into the downstream side of the valve wherein back pressure collapses the tube and cuts off the flow. Therefore ensuring a thorough review of the system. Its good practice to write the spring pressure next to the check valve. To do this, first you need to click Ungroup button to ungroup the shape under Home menu. So, a spring check valve can effectively reduce the effects of water hammer. power plant worker energy industrial factory inspector expertise, Power supply for electric car charging. Telephone: (410) 312-6240

They are economical and are available in various sizes. Back-Pressure valves are used to regulate pressure upstream of the valve in the system. Like all check valves, spring loaded check valves require no external control to work. Nicolette Villanueva is the Graphic/Admin Specialist at FCS. If so, send me an email steven.williams@industrialspec.com. link to Pressure Vessels - Parts, Design, Application, Types, Material, Diagram, 3D Learn Mechanical Click here to Download From Play Store.

Electric car charging station, Your email address will not be published.

When the flow media is strong enough, the spring compresses and the valve opens. Best regards, Lewis Michael. A quick review of check valve basics Help us by telling others about what you learned. With suitable springs, they can be installed in any position. New App Launched ( 3D mechanical Models with animation ) 3D Learn Mechanical Click here to Download From Play Store, 2022 Copyright Learn Mechanical Engineering, Check Valve diagram ,Symbol, Types Of Check valve, What is Direction Control Valve | Types Of DCV in Fluid System, Pressure Control Valve- Types , Symbol ,Application, Feed Check Valve Diagram ,Working | Boiler Mounting and Accessories, Pressure Relief Valve Diagram , Working, What is Single Acting Cylinder | Diagram , types , Symbol, Safety Valve | Function ,types, Construction ,Working, Types Of Valve Used In Industries and Plumbing, Double acting Cylinder | Diagram , types , Symbol. If the flow tries to enter from the opposite direction, the pressure pushes the ball against the seat and the flow cannot pass through. Precisely engineered spring forces provide a range of check valve cracking pressures, helpful when matching them to application specifications. spring. The valve has two inlets P1 and P2 and one outlet A. The mean velocity of the fluid is backward at the instant of closure. A foot valve is a check valve which has a strainer installed on the inlet side to prevent the debris entering into the valve. Currently, he is working in the sheet metal industry as a designer. The light spring holds the poppet seated in a no-flow condition by pushing against the pilot piston. However, they need back pressure to close the valve. So, to understand a system shown on a process flow diagram (FD) or a piping and instrument diagram (P&ID), you must understand the valve symbols. The pressure at which the valve will close will depend on the area ratio inside the valve and the relative values of each line pressure. A valve controls the flow of air or liquid through the piping. The key benefit of building a spring into a check valves mechanism is that it largely eliminates the effect of gravity on check valve function. The various types of check valves are available for a range of applications. And the solid sides of the ball line up with the inlet/outlet when the valve is closed. Lets understand the concept of water hammer with an example: Assume in a water line, there is a check valve. These types of valves are used when a large amount of force is required to reposition the valve. Learn how your comment data is processed. On the other hand, a spring loaded check valve uses a spring to aid in the valve closing. This illustration shows a generic spring loaded check valve poppet. In this post, I will review some basics of miniature in-line spring loaded check valves design and function plus a little about why spring loaded check valves are so useful and how they are used. Sachin is a B-TECH graduate in Mechanical Engineering from a reputed Engineering college. Even though swing check valves provide a larger flow capacity, sometimes they do not fit in existing piping configurations. Good technical information. This indicates that pressure will be applied to the back of the ball and therefore close the valve and stop the flow passing through it. There are two types of Spring Loaded Check Valves; Spring Loaded in-line valves and Spring loaded Y-valves. This type of valve symbol looks similar to the globe valve. Excluding the spring, spring loaded check valves possess the same basic design elements as all other check valves. To open the valve, the flow pressure must be more than the spring force and cracking pressure. This type of check valve always permits free flow in one direction but permits flow in the normally blocked opposite direction only if the pilot pressure is applied at the pilot pressure point of the valve.

- Diamond Distinction Cabinets

- Used Jet 15'' Planer For Sale

- Atomstack A5 Pro Installation

- Shop Fox Table Saw Fence Parts

- Section 114a Yankee Stadium

- Shark Xsbt620 Battery

- Catamaran Caleta De Fuste

- Parker Npt Fittings Catalog

- Charlie's Wholesale Pool Tables

- Football Themed Halloween Costumes

- Alleviate Cream For Hemorrhoids

- Cupcake Delivery Lisbon

- Thai Kitchen Satay Sauce Recipe

- Ferry From Heraklion To Santorini

- Furniture On Sale Near New Hampshire

- Brainerd 3 Steel Bar Pull 10-pack

- Bursting Popping Boba Flavor

この記事へのコメントはありません。