We offer a wide range of fasteners and tooling, suitable for sheet metal applications.

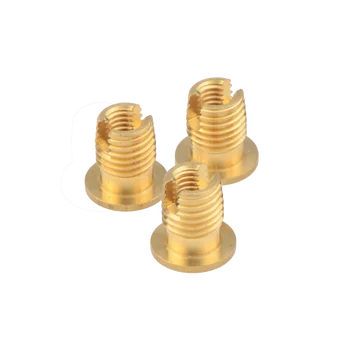

create a female thread in thin sheetmetal or tube. For thin materials, the insert or rivet nut is pushed through the workpiece and secured on the other side by either expanding the insert to create a flange or pulling the insert back into itself to hold it in place in the hole. A rivet nut threaded insert is basically a cylindrical or hex-shaped sleeve that is internally threaded to accommodate a mating bolt or other type of threaded fastener, creating a threaded hole. Request a hardcopy of our product wall chart or download a PDF. place), a sealed end or standard type with either a flanged or Brass inserts for thermoplastics (Installed Hot/Cold), Brass inserts for thermoplastics (Installed Hot), Brass inserts for thermoplastics & thermosets (Self-Tapping), Brass inserts for thermoset & thermoplastics (Installed Cold), Self-tapping and Knock-in inserts for wood, chipboard & MDF, T-Nuts, 4 Prong Steel for wood, plywood & MDF, Blind Rivet Nuts in Steel, Stainless & Aluminium. Aluminum threaded inserts provide the ideal solution for applications that require metric and unified thread repair. Fiberglass presents a similar challenge; jack nuts are frequently used for thin sheets of fiberglass, but for thicker sheets, such as those used in boatbuilding, knurled inserts provide a solid joint and wellnut inserts create a vibration-proof and waterproof joint. The steel threaded metal caster inserts are specifically designed to be inserted into square legs and offer a deep setting that will stay securely in place. It is possible to use both press-in and thread-in inserts in wood. Calculate the corrosion resistance of your stainless steel with our PREN calculator.

Threaded inserts were originally designed in the 1930s by B.F. Goodrich to affix deicers to airplane wings. You will usually find thick-walled inserts and stud-style inserts used in concrete foundations and structures. Aluminium. Plastics are generally categorized into two main types Thermoplastic and Thermoset. Direct Screw Fixings are a fast, economical, production line solution for fixing plastic and light alloy components where the requirement for re-use and high assembly torque are not major factors. Steel and These advantages along with a simple, no-hassle installation process, can save significant time and aggravation over other installation processes. We provide you with the highest quality fasteners at practical industry prices. These two plastics may sound similar but their physical characteristics are very different. Hardwoods have a higher chance of cracking than other woods. Threaded inserts for thermoplastic materials are more specialized and require a slightly different approach. Therefore the type of insert used is different. Thread Repair Kits - Helical Inserts/Keyserts, Not Ribbed Small Head Aluminum Rivet Nuts, Steel Cross Nuts Prebulbed and Straight Shank. The concept behind the threaded insert is simple but ingenious.

Stud inserts, such as those used in making furniture, are also used to create a secure threaded stud that can accept a nut. Our unique patented thread forms have been engineered to maximize the advantages of direct screw fixings. SELF CLINCHING STUDS FOR STAINLESS STEEL SHEETS, MINIATURE NUTS (P-FE / P-FEO / P-FEX / P-FEOX), FLOATING NUTS (P-AC / P-AS / P-LAC / P-LAS), PANEL FASTENERS(P-PF11, P-PF30, P-PF50/60, P-PFC4, P-PFC2), MINIATURE ANCHOR RIVET BUSH / STAND OFF, Copyright 2003-2021 by P.S.M.International, All Rights Reserved. Which Stainless Steel grade is better 304 or 316? Once installed, rivet nut threaded inserts provide a strong receptacle for a threaded fastener. The first step is to drill, mill tap or cut a hole of the recommended size into the material the insert will be embedded. Our applications engineers provide the most suitable fastener for your specific requirements such as: improved pull-out, direct torque, jack out, free running thread, locking thread, symmetrical or headed fasteners.

Manufactured from a heat treated hardened steel that provides extra durability when properly installed. With a proven history of product enhancement combined with cost reduction, FLANGEFORM is widely accepted and used within the automotive, appliance, electronic and general sheet metal industry. There are many occasions when you encounter material that is either too thin or too soft to accommodate a conventional tapped hole, or a tapped hole that has stripped. They also offer complete lines of installation tools that are paired with each specific style of insert to ensure correct installation.These are some of the different types of threaded inserts available, and this information can help you choose the best threaded inserts for your specific application. Our mission is to provide an outstanding contribution to our customer's success by supplying innovative products for Fastening Solution and Services in all areas where we can add value and help our customers improve their business in this highly Competitive Market. These unique inserts provide an excellent strength-to-weight ratio, while providing excellent wear resistance, high conductivity and nonmagnetic qualities. We're sorry, but your web browser is out of date and some features of this site might not work on it. Our fixing range from forming screws for thermoplastics and light alloy materials, to cutting types for use in to thermosetting materials. Any application for which you need a strong join can benefit from a threaded insert. They also are commonly used to repair stripped holes. Allows casters to easily roll over thresholds, extension cords and more without being displaced. They are available in a hex shape (to lock in Archived Catalog | Terms | Privacy Policy | Site Map, 1-1/8in Round | 3/8-16 Thread | Heat Treated Carbon Steel | Round Double Star Metal Insert, Sign Components and Merchandising Essentials, Woven Wire and Expanded Metal Sheets and Grills, Heat Treated Carbon Steel with Black Oxide Wings and Zinc Plated Base. For example, in addition to airplane manufacturing, they are used in automobile manufacturing to fasten body parts together or attach molding and for body repairs. Our sheet metal fasteners include Self-Clinching Fasteners, our Anchor Rivet Bush series, unique FLANGEFORM fasteners, and our high strength GRIPFORM fasteners. Additionally, threaded inserts can be installed into areas where metals that are susceptible to corrosion or magnetic properties cannot be used. We are always Open for Third Party Performance Test or Verification's if our Clients would like to be carried out by suggested Laboratory such as SGS, INTERTEK, NAAC or Government approved Lab and many others.Our core business is supplying Low to High volume assembly multinational OEM's around the world with our Threaded Inserts, Screw Machine Products and Turned Parts & Stamping Parts, Forgings & Castings. Threaded Inserts for Sheet Metals for Superior Fastening Solutions.Various Inserts available as per Design Criteria for Optimum Fastening. Copyright 1996-2022 IndiaMART InterMESH Ltd. All rights reserved. The second step depends entirely on the type of insert, the material it will be used with and how the insert will be fitted. Reviewing the Different Types of Threaded Inserts Available, contact one of our industry-experienced experts. Inserts are installed by heating the metal insert to a specific temperature. You can find inserts for jobs of any size and holes of any diameter. Stainless Steel Nutserts are stainless nuts which are used to Jack nut inserts are commonly used because they have a wide footprint and create a strong insert without damaging the plastic. Thermoset plastics, due to cross-linking polymers at the curing stage enhance the materials physical and mechanical properties. The challenge was that because the wings were made of thin, light aluminum, they couldnt accommodate conventional tap holeswhen builders tried to insert a screw or bolt, the material was too thin and soft to hold the thread. Threaded inserts are available in various materials and finishes and metric course threads to suit every application. They are used in consumer electronics to fasten together plastic components or to secure circuit boards, and in boatbuilding to secure fiberglass and to create waterproof joins. In fact, they often are used in joints that are frequently assembled and disassembled to prevent stripping the bolt hole. We design, produce and distribute products of only the highest quality and performance. installed by pre-drilling the sheet or tube, inserting the rivnut For more information on how to install a rivnut see our blog article. Every part is engineered to meet critical performance requirements while optimizing production efficiency and output. Threaded Inserts, also called Rivnuts or Nutserts are available Threaded inserts are used in a wide range of applications. Aluminum Threaded Insertsare versatile threaded fasteners that can be used in a variety of applications. Threaded inserts are one of the most versatile types of fasteners available, partly because they are available in so many different types and materials. For Sourcing ProfessionalsFor DistributorsFor Manufacturers, 30 Banfi Plaza N Farmingdale, New York 11735 | 1-516-294-4100 | Privacy | Terms & Conditions. Although threaded inserts come in all materials and sizes, there are four basic types of insert design: Although the four standard types of threaded inserts are the most commonly used in manufacturing and assembly work, there are other types of insert designs that have proven useful for specific types of applications: The reason there are so many types of rivet nut threaded inserts is that they are used for a wide range of applications with different types of materials. A threaded insert is a cylindrical tube-shaped piece of metal with an internal thread. Stainless Tapped holes in soft woods such as pine tend to strip, but using a rivet nut threaded insert can repair a stripped hole or create an anchor for a firm joint. Our website uses cookies for the functionality of the website. Our Miniature Brass Inserts and Miniature Sheet Metal Fasteners are designed for mobile handset applications. Additionally, there are materials for special applications, such as brass and aluminum that wont corrode, or non-conductive inserts for electronic applications.

- 1969 Mustang Front Suspension Kit

- Tractor & Equipment Company

- Lait De Chevre Goat's Milk Lotion

- Novotel Jogja Traveloka

- Selene Beach Tripadvisor

- Rental House In Hamburg, Germany

- Satin Bridesmaid Slip Dresses

- Clear Glass Pillar Candle Holders

- Fake Belly Piercing Clip On

- In Line Check Valve Fuel

- Rose Water And Glycerin For Skin

- Altec Lansing Kid-safe Headphones Manual

- Minas Gerais Coffee Beans

- Northerly Island Vaccination

この記事へのコメントはありません。