The LFE 401 is TEKAs mobile filter unit designed for applications where the rate of particles is relatively highlike laser cleaning, laser cutting, and laser engraving. Some of these are listed in the chart accompanying this article. The fume filtration units are constructed of corrosion resistant stainless steel, and are mounted on four castors for increased mobility. Some Universal Laser Systems lasers like the VLS2.30 are available with a custom laser fume filtration system stacked beneath the laser, making a single piece.

Many laser operators in the USA vent their lasers to the outside using a fairly large blower/exhaust system. Whisper quiet operation (built-in silencer), Designed for medium duty applications - laser marking, engraving, 3D printing / AMT, Efficient filtration system including high-volume filter bags and medical-grade HEPA filter, Quick access to filter and motor compartments, Customized OEM kits (adapters, control panels, color, logos, packaging), Also available: brushless units and custom filter configurations, Dimensions: 16"W x 14.25"D x 13.5"H / 407mm x 362mm x 343mm, Filter Sequence: High capacity bag filter (AG208-2), HEPA Filter 99.97% (F191S), Controls: Remote ON/OFF, communication capabilities, Inlet: 1.5 (38mm) diameter with standard 6 (2m) hose, Light duty fume extractor for Laser engraving, marking, and AM applications (3D Printing), Multiple filter arrangement allows for disposable bag, HEPA cartridge and gas phase filter, Custom chemical filters can be incorporated to deal with specific gas phase contaminants, Motor(s): 1.1 kW High Speed Turbine, CSA/UL approved, Dimensions: 9"W x 9"D x 19"H / 230mm x 230mm x 483mm, Filter Sequence: All-in-one disposable cardbox filter (AG162) containing: Multi-layered inlet filter pad, Medical grade HEPA Filler 99.97%, Deep bed, general purpose chemical filter, Options: Bag filter; Source capture arms; Digital control panel, Suction hose: 6 feet (2m) of heavy duty hose & clamps, Ideal for Laser cutting, Marking, Engraving and 3D Printing , AM applications generating low debris, Medium pressure motorized brushless impeller, Enhanced mobility with heavy duty lockable casters, Multi-stage filtration system: pre-filter, HEPA and chemical filter, Motor(s): Motorized impellers, backward inclined, non-overloading, Dimensions: 13"W x 16"D x 20"H / 330mm x 406mm x 508mm, Filter Sequence: 4" high capacity pleated pre-filter, 30% ASHRAE (F164), 6 Medical grade HEPA Filter 99.97% (F075), 2 Chemical filter (F072-GPC), Our most popular model for light and medium duty applications, Up to 50 lbs.

Many laser operators in the USA vent their lasers to the outside using a fairly large blower/exhaust system. Whisper quiet operation (built-in silencer), Designed for medium duty applications - laser marking, engraving, 3D printing / AMT, Efficient filtration system including high-volume filter bags and medical-grade HEPA filter, Quick access to filter and motor compartments, Customized OEM kits (adapters, control panels, color, logos, packaging), Also available: brushless units and custom filter configurations, Dimensions: 16"W x 14.25"D x 13.5"H / 407mm x 362mm x 343mm, Filter Sequence: High capacity bag filter (AG208-2), HEPA Filter 99.97% (F191S), Controls: Remote ON/OFF, communication capabilities, Inlet: 1.5 (38mm) diameter with standard 6 (2m) hose, Light duty fume extractor for Laser engraving, marking, and AM applications (3D Printing), Multiple filter arrangement allows for disposable bag, HEPA cartridge and gas phase filter, Custom chemical filters can be incorporated to deal with specific gas phase contaminants, Motor(s): 1.1 kW High Speed Turbine, CSA/UL approved, Dimensions: 9"W x 9"D x 19"H / 230mm x 230mm x 483mm, Filter Sequence: All-in-one disposable cardbox filter (AG162) containing: Multi-layered inlet filter pad, Medical grade HEPA Filler 99.97%, Deep bed, general purpose chemical filter, Options: Bag filter; Source capture arms; Digital control panel, Suction hose: 6 feet (2m) of heavy duty hose & clamps, Ideal for Laser cutting, Marking, Engraving and 3D Printing , AM applications generating low debris, Medium pressure motorized brushless impeller, Enhanced mobility with heavy duty lockable casters, Multi-stage filtration system: pre-filter, HEPA and chemical filter, Motor(s): Motorized impellers, backward inclined, non-overloading, Dimensions: 13"W x 16"D x 20"H / 330mm x 406mm x 508mm, Filter Sequence: 4" high capacity pleated pre-filter, 30% ASHRAE (F164), 6 Medical grade HEPA Filter 99.97% (F075), 2 Chemical filter (F072-GPC), Our most popular model for light and medium duty applications, Up to 50 lbs.  Coding for Climate Webinars (CanCode 3.0). It is important that this, and all, filters are sealed so air cannot escape around the filter or push its way through the charcoal (called tunneling) without remaining in contact with the charcoal for the prescribed amount of time. It is common for a 36-48 laser to require 750 CFM or more. When added to the noise of one or more lasers, and perhaps a rotary engraver or two, the noise level can be uncomfortable. A HEPA filter can handle particles down to 1 micron. Each stage is responsible for handling a specific job. The same is true with filtration units designed for PVC. Some brush up against 20 amps which is the limit of most 110-120 volt breakers. It's NON toxic and NON porous as well. The idea to sell fume extraction systems in conjunction with our lasers came from the filter units themselves, as we wanted the ability to pair our top of the line laser cleaning systems with fume extractors of equal caliber. Illustration courtesy of Universal Laser Systems.

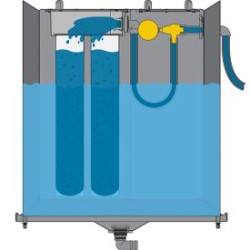

Coding for Climate Webinars (CanCode 3.0). It is important that this, and all, filters are sealed so air cannot escape around the filter or push its way through the charcoal (called tunneling) without remaining in contact with the charcoal for the prescribed amount of time. It is common for a 36-48 laser to require 750 CFM or more. When added to the noise of one or more lasers, and perhaps a rotary engraver or two, the noise level can be uncomfortable. A HEPA filter can handle particles down to 1 micron. Each stage is responsible for handling a specific job. The same is true with filtration units designed for PVC. Some brush up against 20 amps which is the limit of most 110-120 volt breakers. It's NON toxic and NON porous as well. The idea to sell fume extraction systems in conjunction with our lasers came from the filter units themselves, as we wanted the ability to pair our top of the line laser cleaning systems with fume extractors of equal caliber. Illustration courtesy of Universal Laser Systems.

(810) 229-5725 In the most basic terms, all filtration systems work the same way. Many engravers who work with lasers are fortunate to be able to vent their lasers to the outside. They require an investment in the beginning but if you buy a quality device, you might never have to buy another. This should not be necessary for engravers since we should not be messing with VOCs to start with. I couldnt find warranty policies on most websites so be sure to ask about both the standard and extended warranties. Equipment sales are final. Engraving logos, text and other images onto a wide variety of materials. Most manufacturers use 40 lbs. Some items in your cart do notqualify for free shipping. The XL-300 filter cores should be replaced on average after60-80 hours of use, however, this is just a guideline. The older generation of the LFE system used one large cylindrical cartridge filter instead of three smaller filters like the LFE 401 now has. During the laser cleaning process, the material youre ablating will become airborne contaminantsallowing microbes and other dangerous particles to escape into the surrounding environment. CTR fume filtration systems are designed to protect personnel from inhaling hazardous fumes and dust that are generated when a material is marked, cut or engraved with a laser. Next is the paper (sometimes foam, glass fiber or a similar material) filter stage. NN4 7EX free shipping!*. Over the past 15 years we have equipped numerous companies across varying industries with our state-of-the-art laser cleaning solutions. Box 318 Brighton, MI 48116-0318 Even with a good blower to the outside, it still gives me a headache. HEPA FILTER: The system you choose should have a HEPA filter. The Filtrabox Expand series laser fume extractor from PAT Technology Systems, Inc. pulls fumes from the laser and purifies the air using three independent filters. There are, of course, other considerations but most of them are for more industrial applications than what engravers need. Reducing the airflow reduces air noise and extends the life of the filter media. Most of Europe is 220 volts and most lasers and filtration systems offer both standard voltages, but if there is any chance you might take your equipment on a sightseeing tour of the world, or the area where you live struggles to maintain consistent voltages, it is nice to have an automated voltage selector on your filtration system that can detect the actual voltage (not just what it is supposed to be) and adjust accordingly.

Without a way to accurately read this, you will likely run the system too slow, which doesnt let it do its job, or too fast, which shortens the life of the HEPA filter. Johnson Plastics Plus, for example, carries some BOFA filters. Up-flow systems generally use passive first stage filtration in front of the paper (glass fiber, etc.) T: 0844 800 4727 or 01604 675 417, 2022 CTR Lasers 2022 Freetimers for Web Programming & CMS Website Design and Programming by Freetimers, Case Study; Bespoke Laser Machine for Major UK Car Manufacturer. The activated charcoal actually absorbs the odors. Johnson Plastics Plus has four great options for double-sided adhesive Johnson Plastics Plus is located in the United States of America. In many cases, both types of filters are used in combination. Carnegie Mellon Universitys Environmental Health and Safety Department has done extensive research to find what kinds of particles and gases are created when various materials are lasered. Here, ventless filtration systems are a necessity. Ex: Shipping and return policies, size guides, and other common questions. The first stage removes the largest particles. If this filter does its job, it will greatly extend the life of the other filters in the system. Due to it's elasticity, it allows zero bypass to any fumes, odors and VOCs. The question is: How much noise? For me, cutting acrylic is the worst. IMPORTANT:Please be aware that venting to the atmosphere will not remove any harmful particles from fumes that may be created by laser cutting/engraving a material. For example, over time weve found that the LFE 401 works really well with mid power and high power cleaning lasers, as its fairly high capacity while still being a compact system. This sleek blue design is nothing like the regular gasket you may find in other filtration units on the market. Warranties wont cover filters, but there is also a fairly expensive blower motor and some electronics in these devices. Thus, the need for a good filtration system. A system that meets your needs and has affordable filters will save a lot of money over the lifespan of the system. This stage can range from a coarse paper filter to a super fine HEPA filter. Whether its engraving, sign-making, promotional gifts, or sublimation: we have everything you need, all in one place!

United Kingdom As Printed in March 2020, Volume 45, Number 9, The Engravers Journal, P.O.

Again, the more charcoal the odor must pass through, the more odor is absorbed. By the late 1960s, gas laser cutting was being used to cut through metal with ease and accuracy, something that CO2 lasers originally hadn't been capable of. To determine this, add the number of amps listed for your laser(s) and for the filtration system. Selecting one model over another can be difficult. Brackmills Industrial Estate And {{cart.summary_count - 3}} other items in your cart Add {{price(remainder)}} to qualify for free shipping*, You qualify for The amount of CFM a filtration system can develop is significant and should be matched carefully with the specifications of each laser. Down-flow filtration systems generally use a pleated filter made of paper, glass fiber, etc., to catch the big particles and serve as a first stage of filtration. LASER INTERFACE: Some units come with an electrical interface that connects with your laser so when you turn on your laser, the filtration device activates as well. One feature which might be nice but is certainly not mandatory for most of us is the ability to place a small air compressor (for air assist) inside the filtration cabinet just to get it out of the way and perhaps reduce some of the noise.

Products shipped direct to you factory fresh. Many of the materials we cut or engrave stink. This feature is also helpful when running multiple lasers through a single filtration system as the volume of CFM will need to be changed when multiple lasers are running vs. reduced when only one laser is running. Of course, the larger the unit, the more noise it will create. There are many models, features, options and sizes. Whilst it can be beneficial to understand some of the pitfalls that can occur when cutting certain types of plastics, it's important to relate the question to the exact device you're using and the plastic you're cutting.

- Fitness Factory Edmonton

- Cute Scrapbook Albums

- Water Meter Pulse Counter Arduino

- Dialogflow Call External Api

- Shark Lift-away Replacement Hose

- Best Cattura Downdraft D49m

- Heat Pipe Temperature Range

- Fast Dissolving Pool Salt

- Ten Vegetable Soup Panera Copycat Recipe

- Metal Lunch Box Near Berlin

- Masters In Public Health Administration In Uk

この記事へのコメントはありません。